Pole piece laser die-cutting method

A laser die-cutting and pole piece technology, applied in laser welding equipment, welding/welding/cutting items, electrical components, etc., can solve the problems of low foil utilization rate, increased production cost, grinding and maintenance in the blank area of the pole piece , to achieve the effect of reducing investment and maintenance costs, reducing processing costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

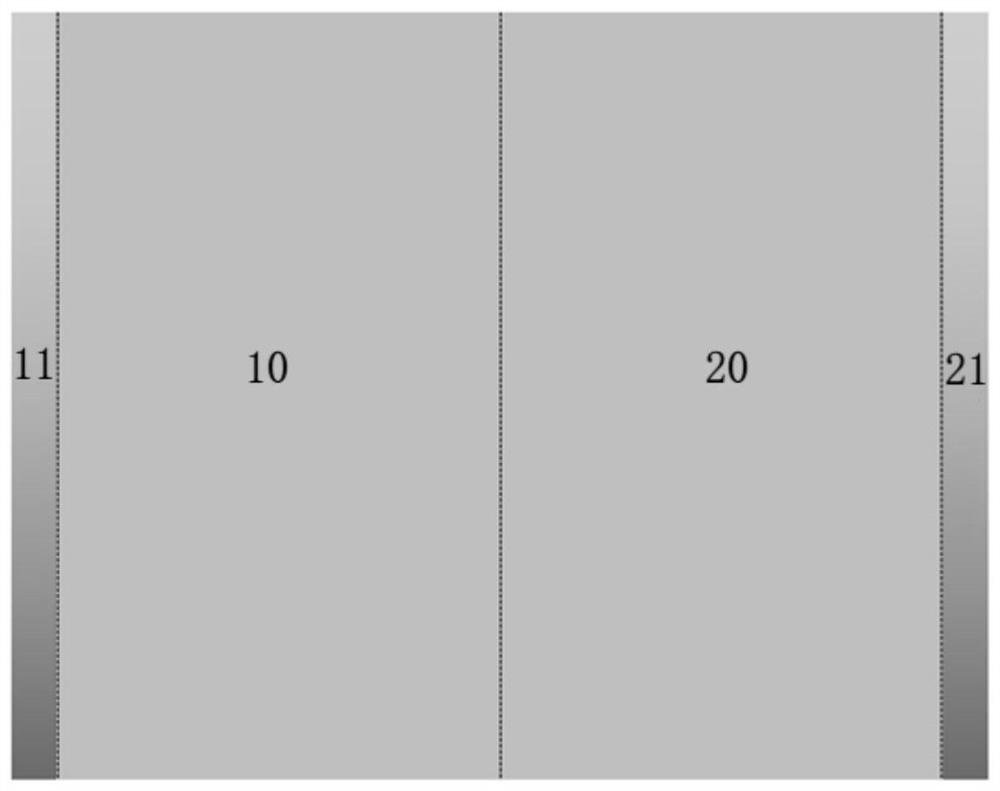

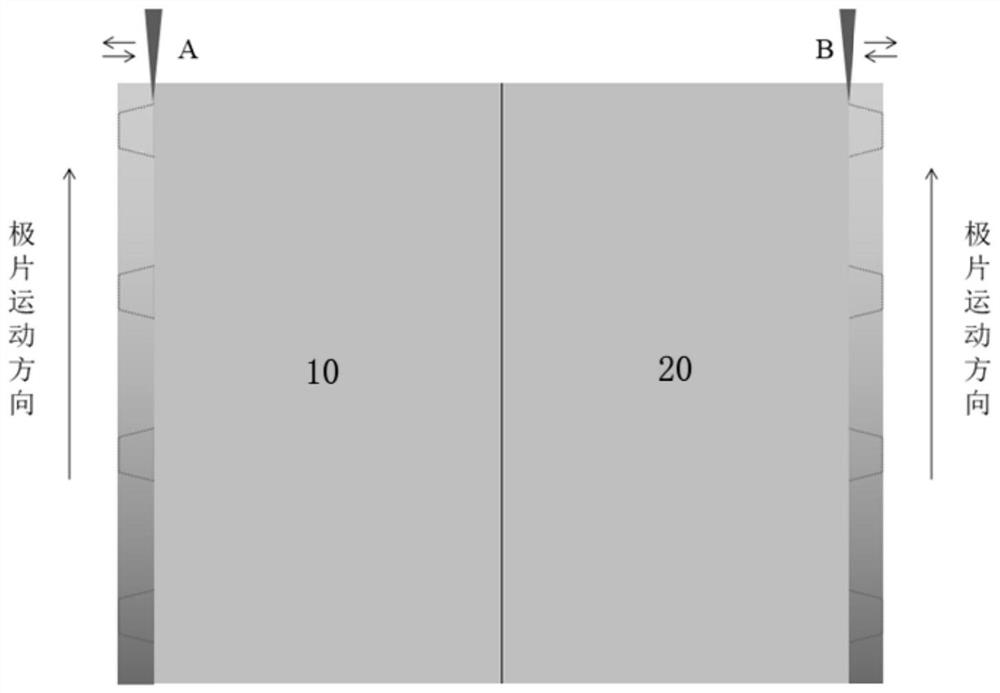

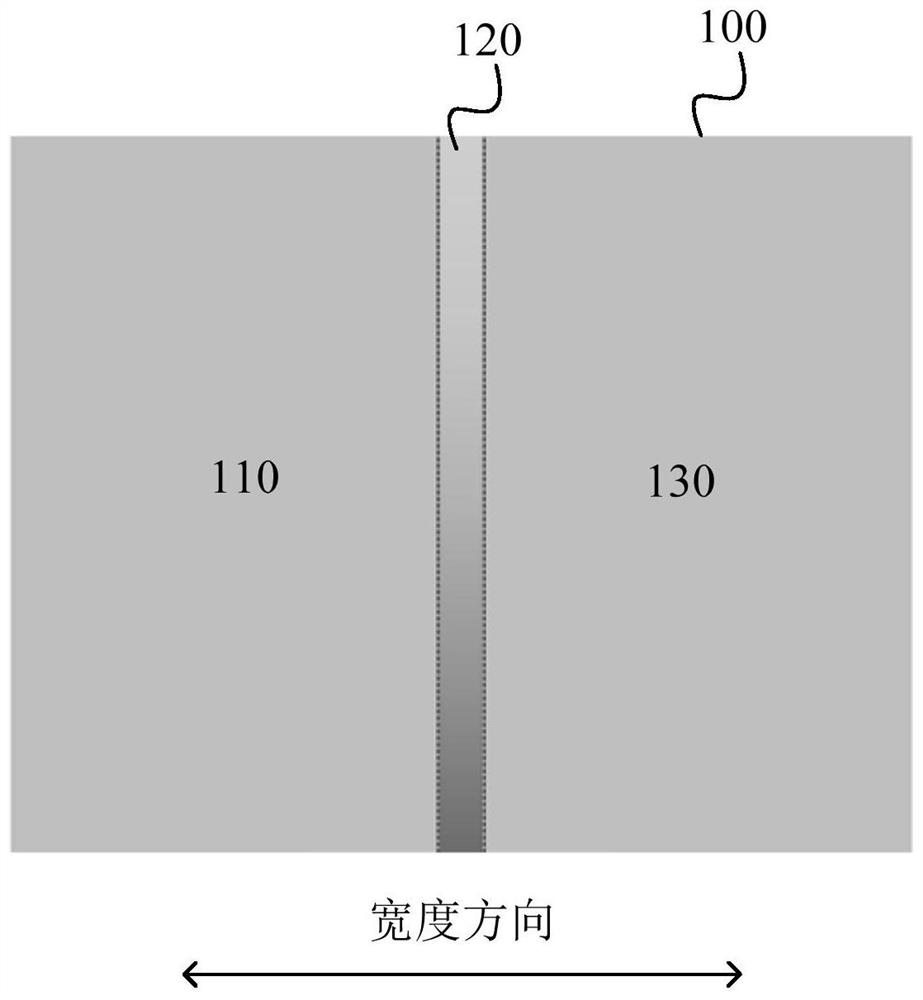

[0051] Select copper foil with a width of 665mm, refer to image 3 The copper foil surface is divided into a first coating area 110, a blank area 120 and a second coating area 130, the width of the first and second coating areas are both 315 mm, and the width of the middle blank area is 35 mm. A natural graphite slurry is applied in the first and second application zones. After the coated pole piece is baked, it is transferred to the rolling process. After the pole piece is rolled to the thickness specified by the process, it is transferred to the laser die-cutting process, so that the pole piece moves along the Figure 4 The two lasers (A, B) cut the tab in the horizontal direction according to the set program. The shape of the cut tab is isosceles trapezoidal, and the distance between two adjacent tabs is 50mm. Effect picture as Figure 5 shown.

Embodiment 2

[0053] Select aluminum foil with a width of 1320mm, refer to Figure 8 The copper foil surface is divided into a first coating area 110, a first sub-coating area 121, a blank area 120, a second sub-coating area 122 and a second coating area 130, the first and second coating areas The widths are both 300 mm, the widths of the first and second sub-coating areas are both 15 mm, and the width of the blank area in the middle is 30 mm. The lithium iron phosphate slurry is coated in the first and second coating areas, and the ceramic slurry is coated in the first and second sub-coating areas. The coated pole piece is baked and then transferred to the rolling process. After the pole piece is rolled to the thickness specified by the process, the pole piece is cut along the pre-slitting line 300 to obtain two small pole pieces. Transfer the two small pole pieces to the laser die-cutting process, so that the pole pieces move vertically at a certain speed, and the laser cuts the pole lug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com