On-line slitting and winding device for wet-process diaphragm of lithium battery

A lithium battery and diaphragm technology, applied in the field of online slitting and winding equipment for lithium battery wet diaphragm, can solve the problems that large rolls cannot be directly coated, cannot flexibly respond to production plan adjustments, and require high equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art.

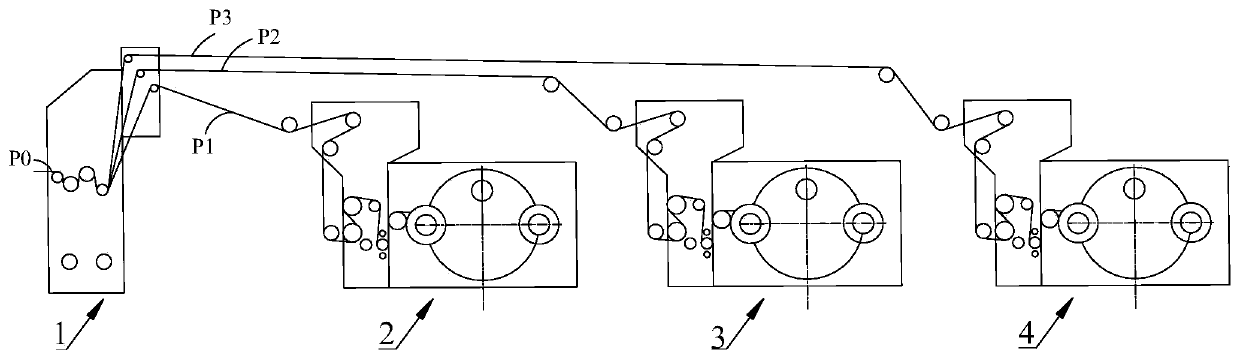

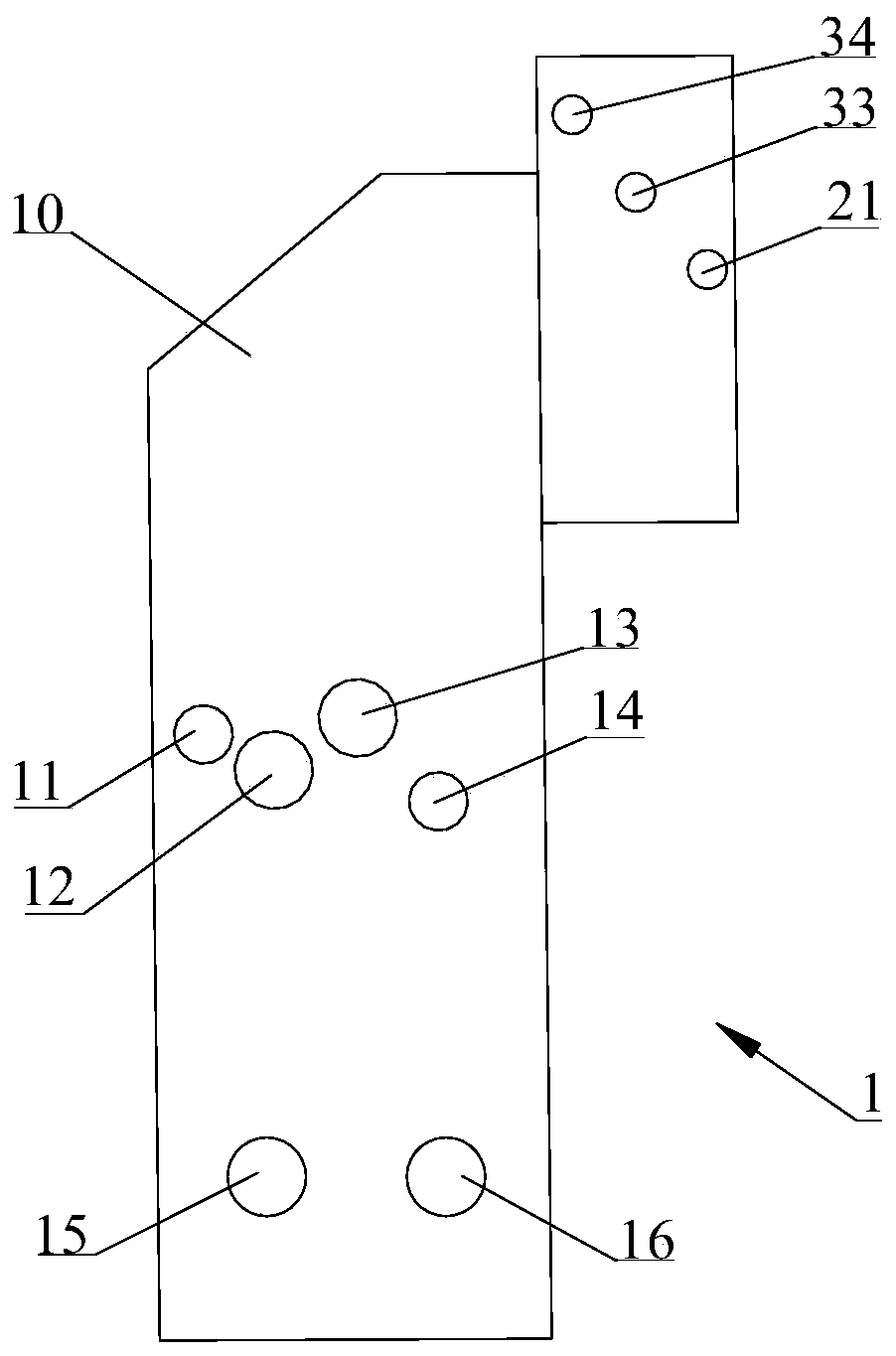

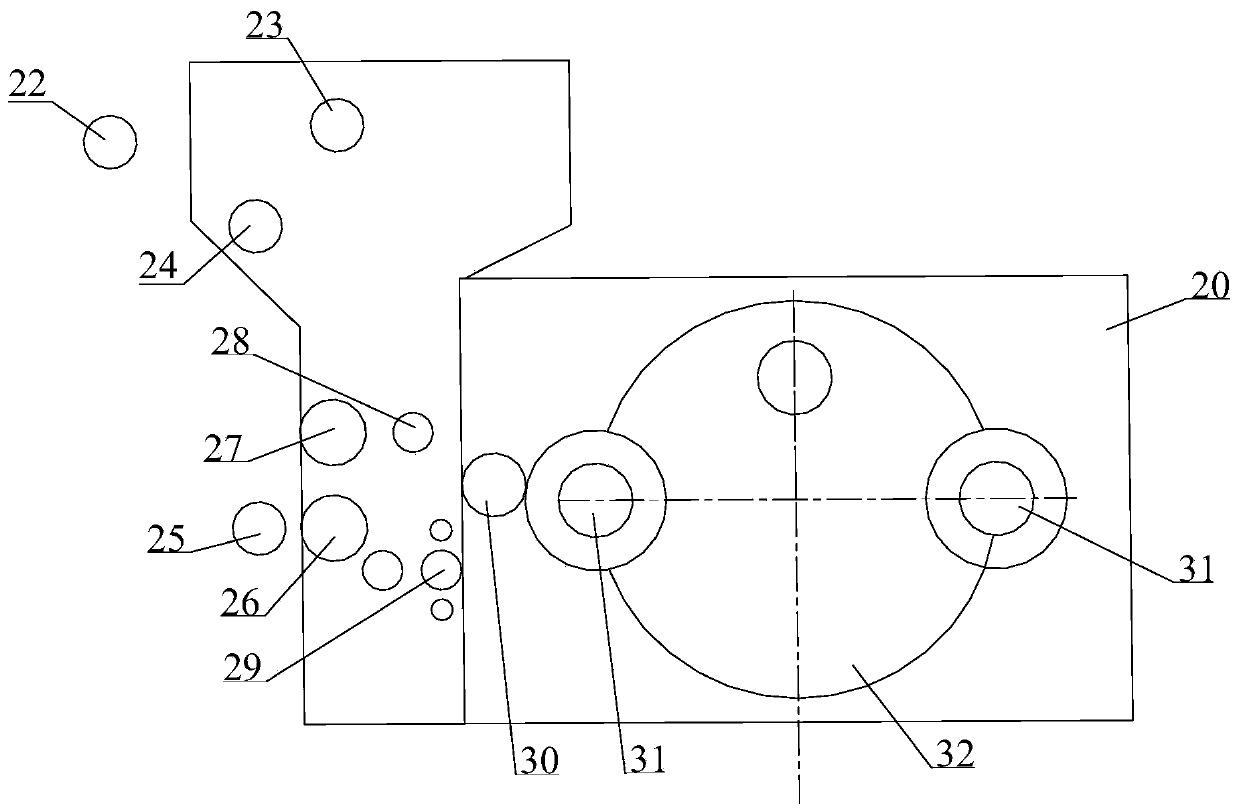

[0030] figure 1 It shows an online slitting and winding equipment for a lithium battery wet separator according to the present invention, which belongs to a part of a lithium battery wet separator production line, and performs cutting and winding for a separator after secondary horizontal stretching. refer to figure 1 As shown, the online slitting and winding equipment includes a slitting mechanism 1 and at least two winding mechanisms, and the number of winding mechanisms in this embodiment is specifically three. The three winding mechanisms are arranged in sequence from front to back and are located behind the slitting mechanism 1, while the slitting mechanism 1 is located behind the secondary horizontal stretching eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com