A battery polar plate coating system and method

A battery pole piece and coating method technology, which is applied in battery electrodes, electrode collector coatings, electrode manufacturing, etc., can solve the unfavorable mass production of power batteries, high material costs and labor costs, and low coating efficiency problem, to achieve the effect of saving pole piece cutting process, significant economic and social benefits, and saving process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

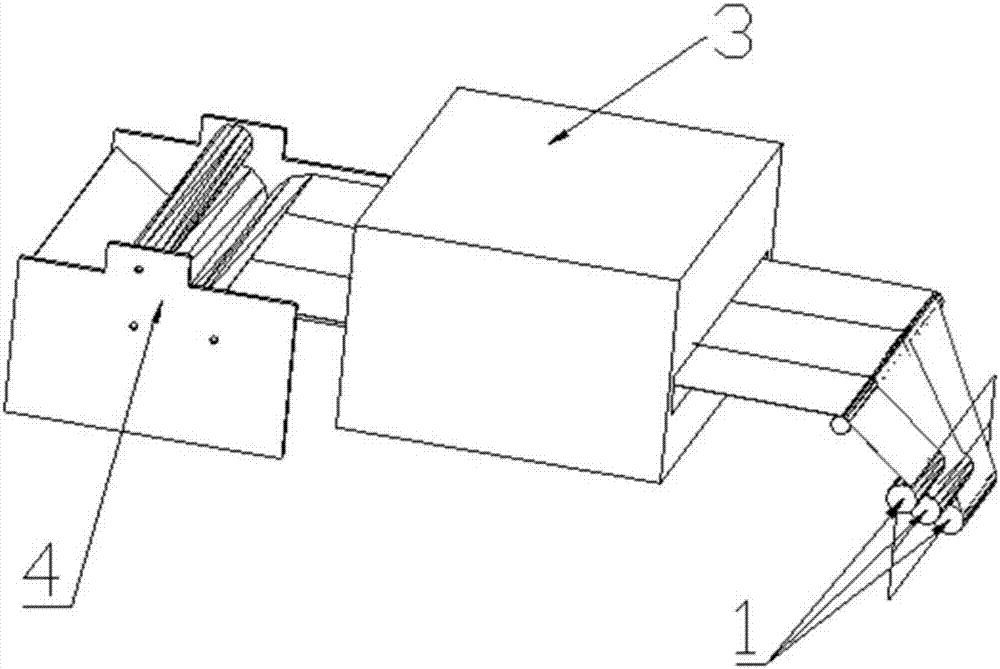

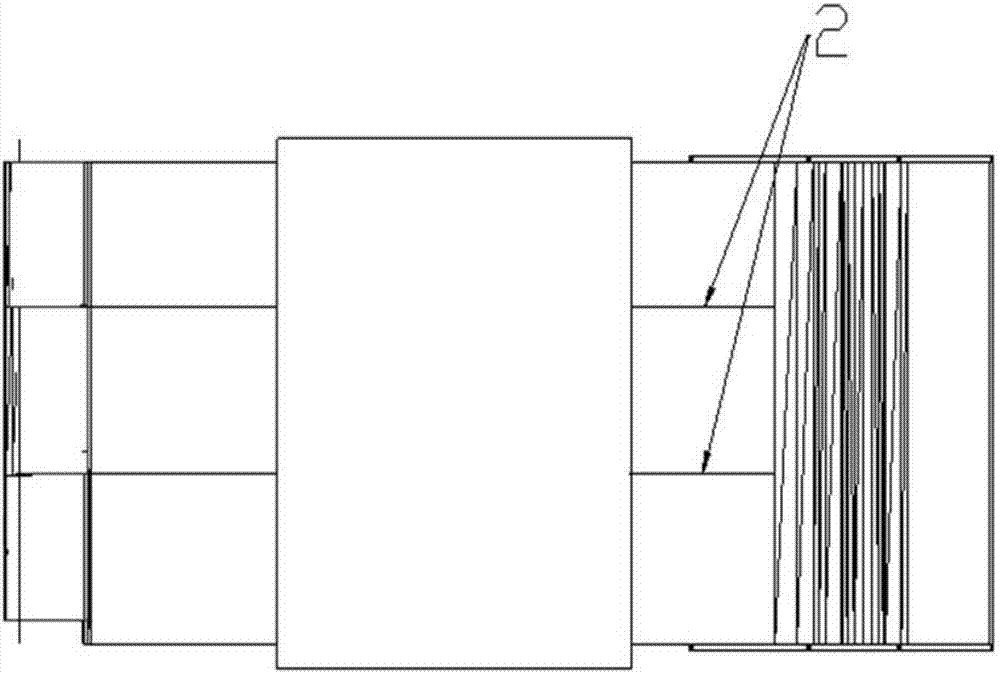

[0048] Embodiment 1: as Figure 1~5 , a battery pole piece coating system, comprising a coating head 4, an oven 3 and a winding device 1; the winding device has 3 independent winding modules;

[0049] Coater head for coating slurry 6 on the foil strip;

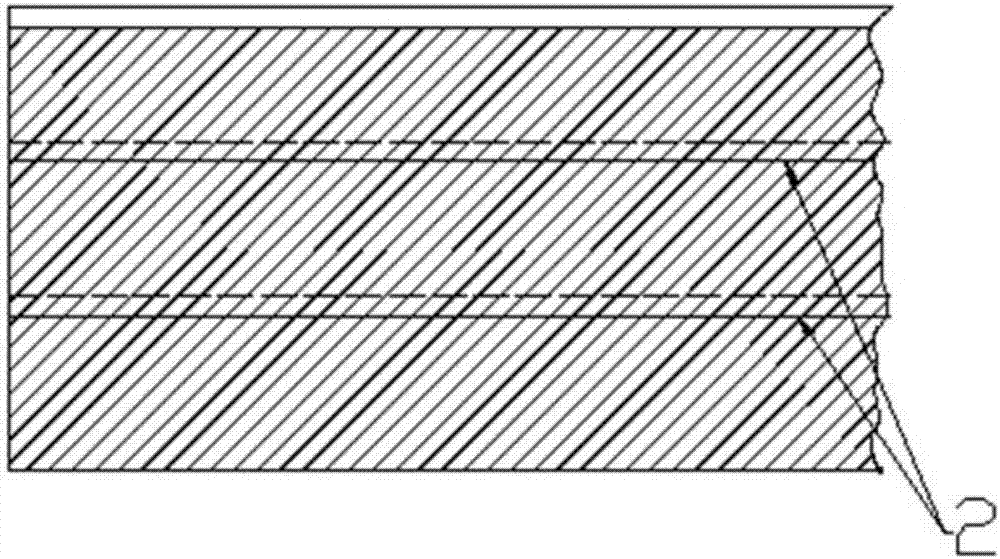

[0050] The foil strip is bonded together by N foil sub-bands through adhesive 2; two adjacent foil sub-bands are spread out in the width direction of the foil strip and partially overlap;

[0051] After the foil strip passes through the oven, the glue loses its cohesive force due to heating, and the three pole pieces are separated and wound up by three independent winding modules of the winding device.

[0052] Glue is adhesive tape.

[0053] The 3 foil sub-tapes have the same width.

[0054] A method for coating a battery pole piece, using the aforementioned battery pole piece coating system for coating.

[0055] The coating steps are as follows:

[0056] Step 1; coating slurry;

[0057] Coating the positive and negativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com