Automatic cutting device and automatic cutting equipment

An automatic cutting device and cutting technology, applied in metal processing and other directions, can solve the problems of low utilization rate of material tape, low cutting efficiency, and high cutting cost, so as to improve cutting efficiency, save cutting process, reduce The effect of cutting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

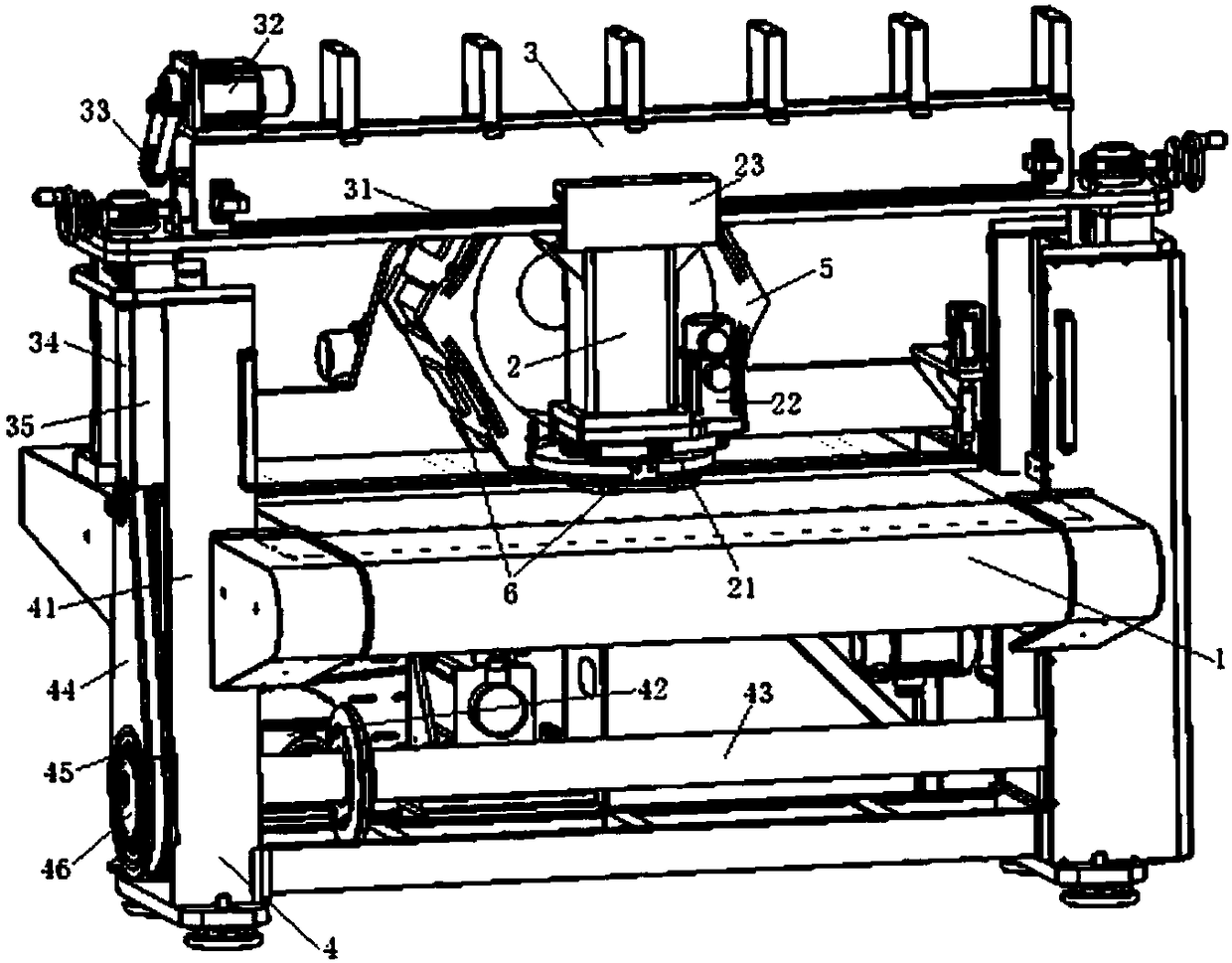

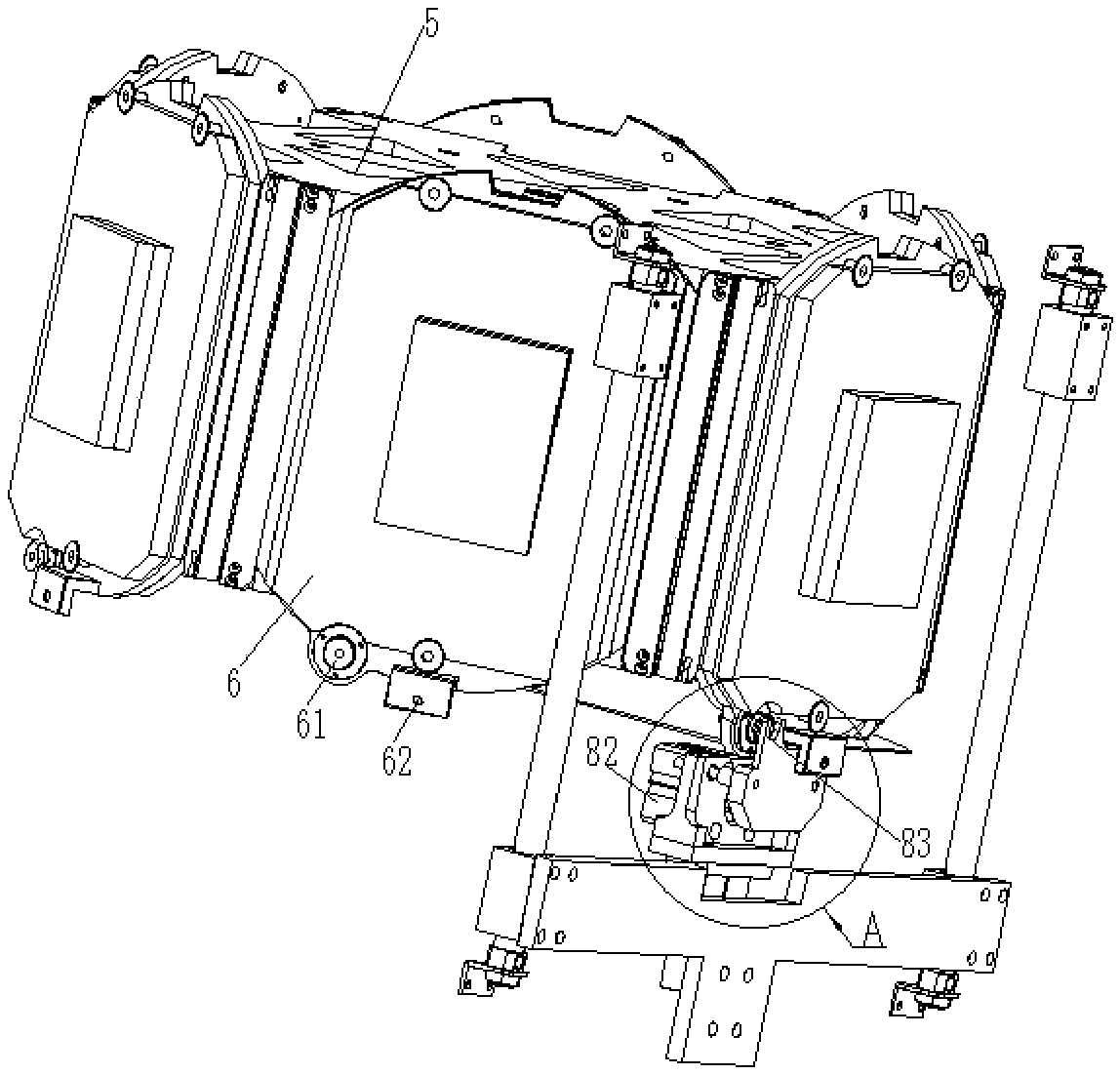

[0038] Such as figure 1 with figure 2As shown, the embodiment of the present invention provides an automatic cutting device, including a conveyor belt 1 for carrying and conveying the material to be cut, a cutting seat 2 capable of installing a knife 6, and controlling the cutting seat 2 to carry out a process on the material to be cut once. Horizontal cutting movement mechanism; the material to be cut is placed horizontally on the conveyor belt 1, the length direction of the material to be cut is the same as the horizontal conveying direction of the conveyor belt 1, and the cutting seat 2 is fixed on the movement mechanism and located above the conveyor belt 1, The conveyor belt 1 can move periodically while the movement mechanism is working.

[0039] The automatic cutting device provided by the embodiment of the present invention includes a conveyor belt 1, a cutting seat 2 and a moving mechanism, wherein the conveyor belt 1 is used to replace the fixed cutting table to ca...

Embodiment 2

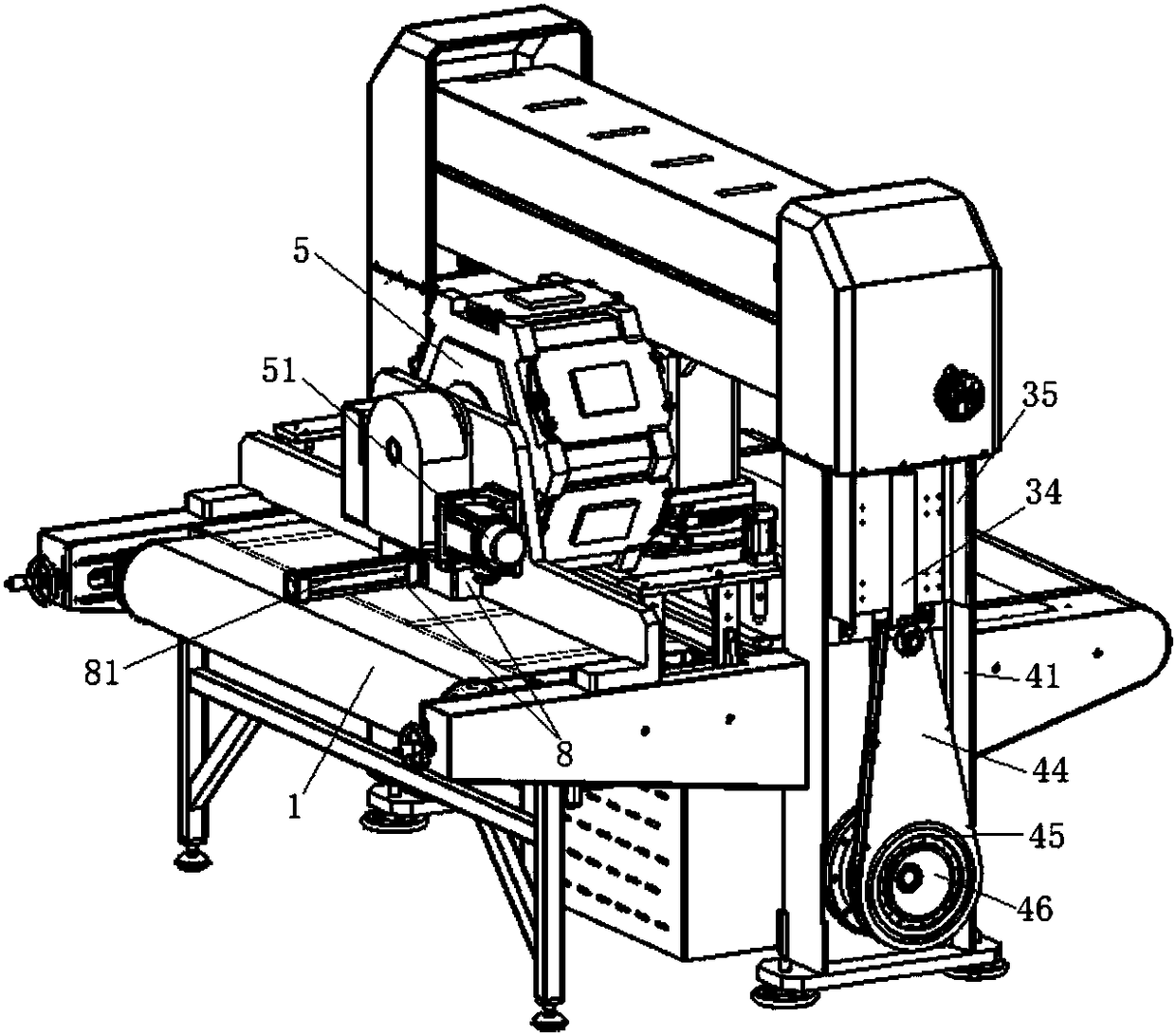

[0063] An embodiment of the present invention provides an automatic cutting device, including the automatic cutting device as described above.

[0064] On the basis of the automatic cutting device, the automatic cutting equipment can also be provided with a tray with materials to be cut and a receiving station for receiving finished products. The tray and the receiving station can be arranged at both ends of the conveyor belt 1 respectively.

[0065]When the automatic cutting equipment provided by the present embodiment works specifically, at first the movable end of the material to be cut on the tray is flattened on the conveyor belt 1, and the corresponding cutter 6 is installed on the cutting seat 2, and then the program is set. Under the premise that the movement mechanism and the cutting seat 2 work, the finished product of the specified shape is cut out on the material to be cut, until the material to be cut is cut in the lateral area of the material to be cut, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com