Four-column semi-submersible offshore floating platform

A floating platform and semi-submersible technology, applied to floating buildings, ships, etc., can solve the problems of aggravating the vertical movement of the platform, increasing the amount of steel used, and the damage of a single column, so as to facilitate large-scale batch construction and reduce the structure The effect of steel consumption and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

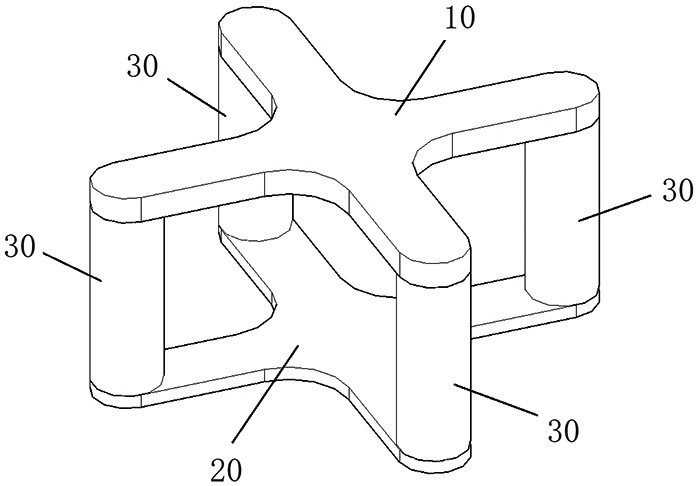

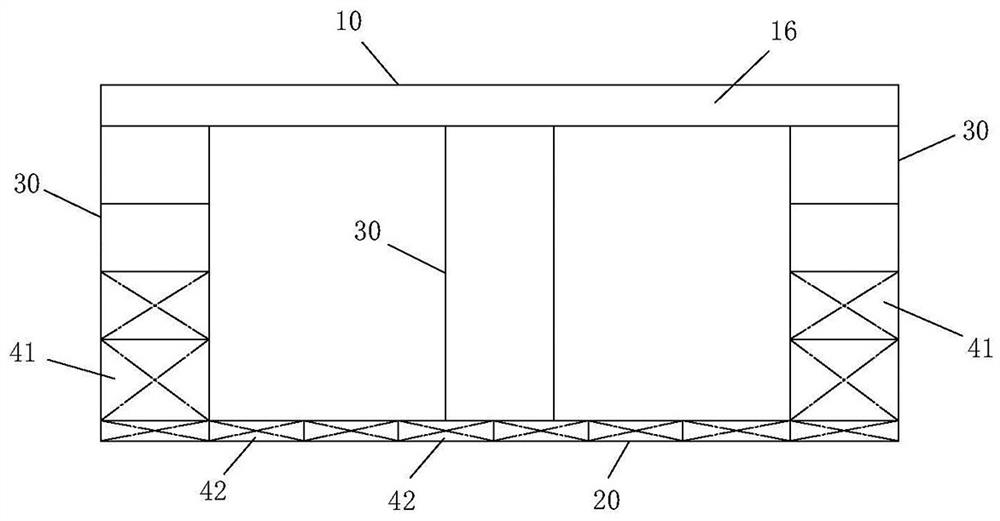

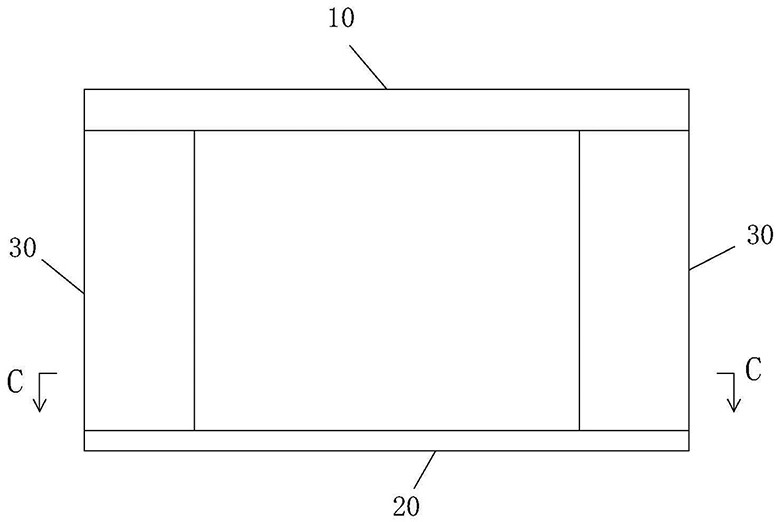

[0040] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, a four-column semi-submersible offshore floating platform includes two box-type components, and the two box-type components are distributed up and down. The two box-like components are specifically: the upper box-like component 10 and the lower box-like component 20 .

[0041] The upper box-like component 10 includes a component body 11 and four laterally distributed arm-shaped pieces 12, and the four arm-shaped pieces 12 are distributed around the component body 11; adjacent arm-shaped pieces 12 are perpendicular to each other.

[0042] The lower box-like component 20 includes a component body 21 and four laterally distributed arm-shaped pieces 22 , and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com