Beveled glass cup machining equipment

A technology for processing equipment and glasses, which is applied to glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., and can solve the problems of low efficiency in manual processing of beveled glasses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

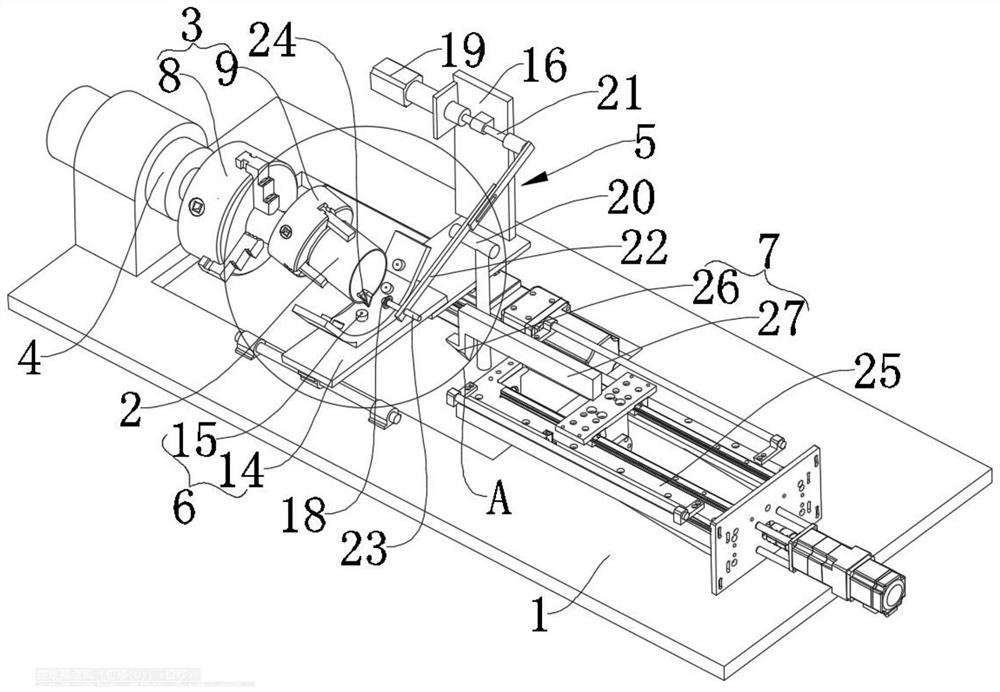

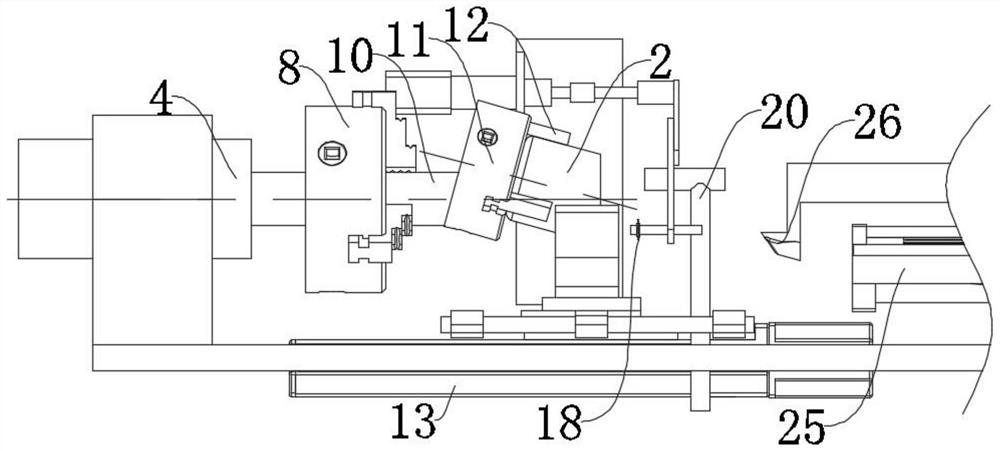

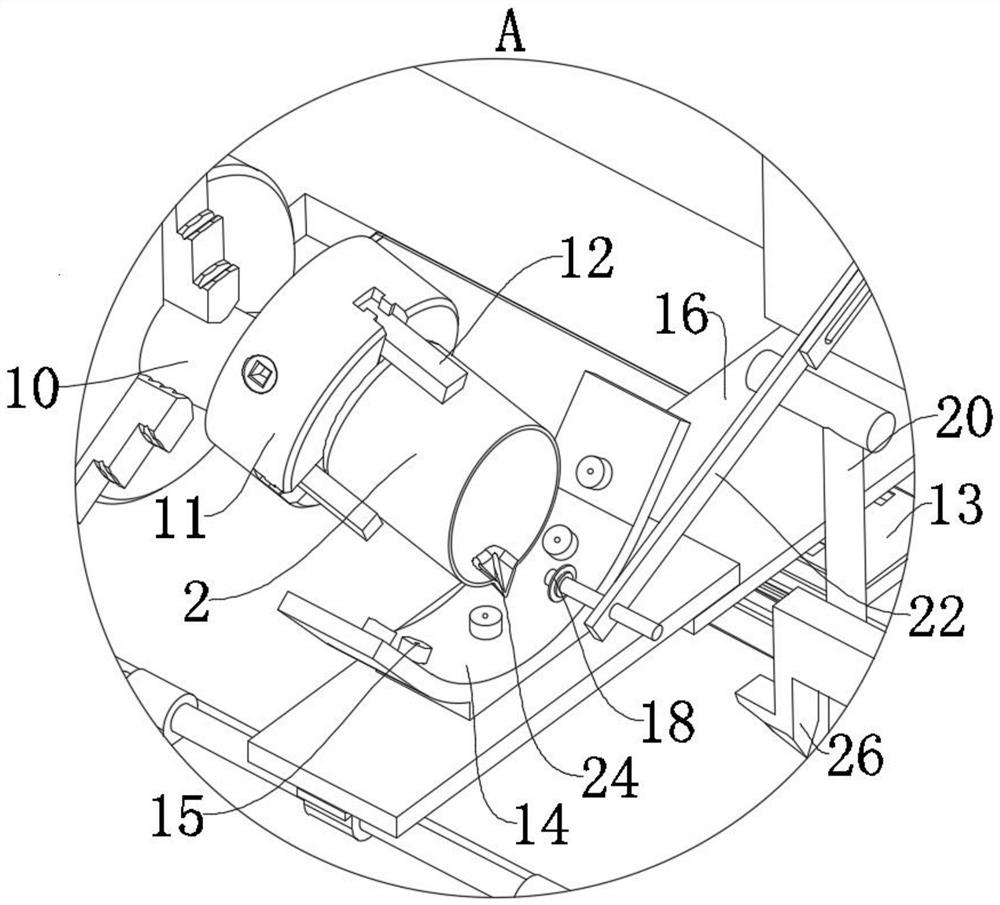

[0034] A beveled glass processing equipment, see first figure 1 and image 3 , including a frame 1, a clamping assembly 3 connected to the frame 1 for clamping the glass cup 2, a driving assembly 4 for driving the clamping assembly 3 to rotate, a cutting assembly 5 for glass bevel processing and a glass The fusing and sintering assembly 6 which is cut and sintered at the incision of the cup 2, the frame 1 is provided with a notch holder 7 which facilitates the formation of the notch 24 of the glass cup 2, the glass cup 2 is first clamped by the clamping assembly 3, and the driving assembly 4 Drive the clamping assembly 3 to rotate, cut the oblique mouth of the glass cup 2 through the cutting assembly 5, and sinter the inclined mouth of the glass cup 2 through the fusing and sintering assembly 6, and pass the waste on the oblique mouth of the glass cup 2 through high temperature along the The gap cut out by the cutting assembly 5 is burned, and after the waste material at the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap