High-temperature-resistant plastic piece and preparation method

A technology of plastic parts and high temperature resistance, applied in the field of plastics, can solve the problems of plastic toughness decline, easy to break, easy to bend and deform of plastics, etc., to achieve the effect of improving quality, improving performance and saving the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

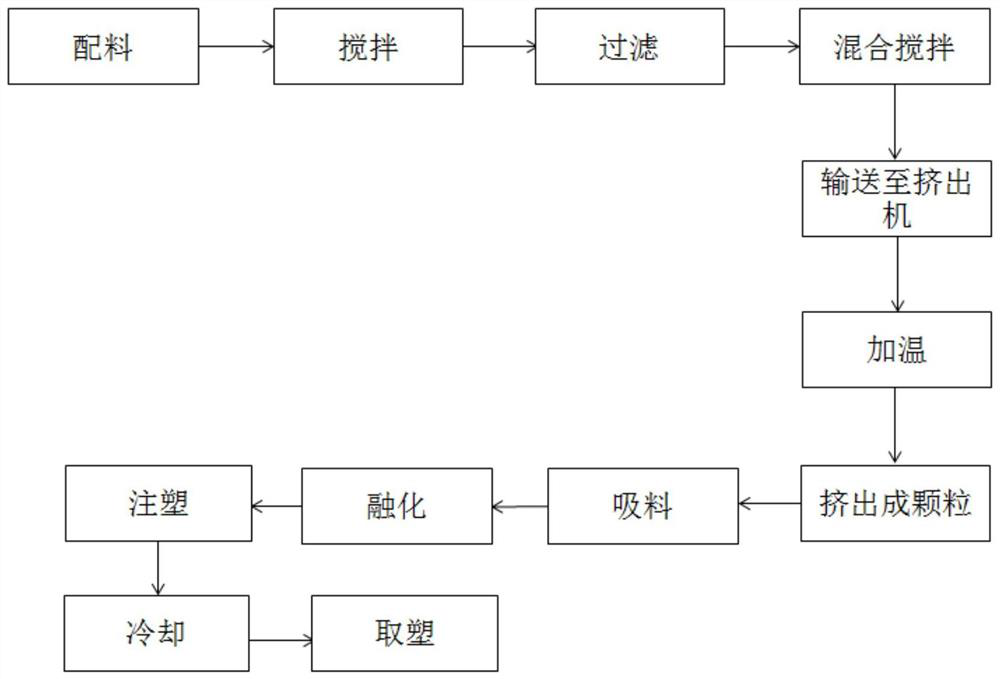

Embodiment 1

[0033] Step 1, take 5 parts of mica, 4 parts of silane coupling agent, 2 parts of antioxidant, 1 part of plasticizer, 15 parts of low density polyethylene resin, 40 parts of high density polyethylene resin, 8 parts of vinyl chloride polymer, 8 parts One part of amino-terminated polymer A is put into a mixer and stirred for 30-60 minutes;

[0034] Step 2, the stirred liquid is filtered through a filter to obtain a filtrate;

[0035] Step 3, put the filtered filtrate ingredients into the mixer and fully mix and stir evenly;

[0036] Step 4, after mixing and stirring evenly, the ingredients are transported to the extruder through the delivery pipe, wherein the temperatures of the first zone, the second zone, the third zone, the fourth zone, the fifth zone, and the sixth zone of the extruder are respectively 55°C, 65°C, 75°C, 85°C, 85°C, 95°C, extruded into granules through an extruder;

[0037] Step 5, and then melt the extruded particles by heating up to 150°C through a plasti...

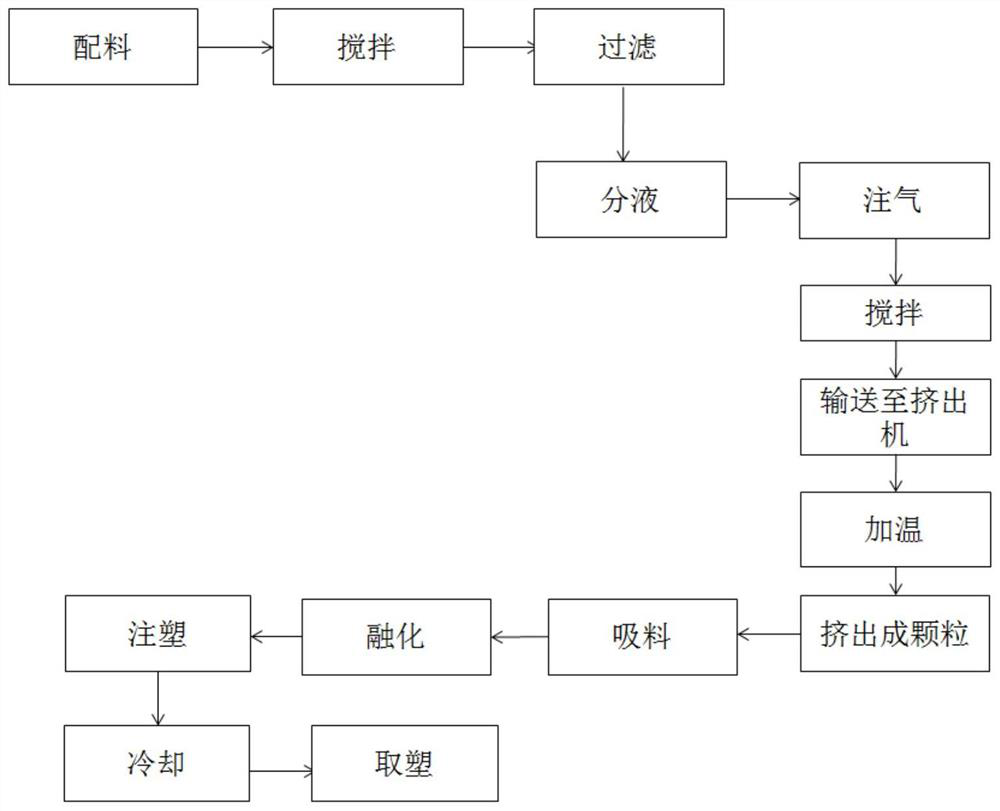

Embodiment 2

[0044] Step 1, get 8 parts of mica, 6 parts of silane coupling agent, 5 parts of antioxidant, 4 parts of plasticizer, 30 parts of low density polyethylene resin, 45 parts of high density polyethylene resin, 15 parts of vinyl chloride polymer, 10 parts One part of amino-terminated polymer A is put into a grinder and ground and stirred;

[0045] Step 2, the stirred liquid is filtered through a filter to obtain a filtrate;

[0046] Step 3, put the filtered filtrate ingredients into the mixer and fully mix and stir evenly;

[0047] Step 4, after mixing and stirring evenly, the ingredients are transported to the extruder through the delivery pipe, wherein the temperatures of the first zone, the second zone, the third zone, the fourth zone, the fifth zone, and the sixth zone of the extruder are respectively 70°C, 80°C, 90°C, 95°C, 100°C, 110°C, extruded into granules through an extruder;

[0048] Step 5, and then melt the extruded particles by heating up to 180°C through a plastic...

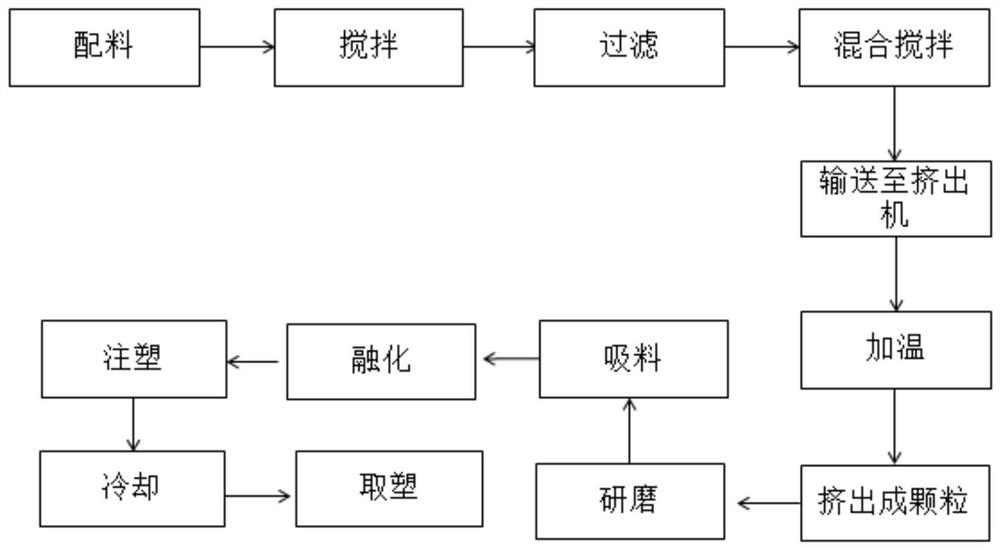

Embodiment 3

[0055] Step 1, get 7 parts of mica, 5 parts of silane coupling agent, 7 parts of antioxidant, 3 parts of plasticizer, 25 parts of low density polyethylene resin, 42 parts of high density polyethylene resin, 11 parts of vinyl chloride polymer, 9 parts One part of amino-terminated polymer A is put into a grinder and ground and stirred;

[0056] Step 2, the stirred liquid is filtered through a filter to obtain a filtrate;

[0057]Step 3, put the filtered filtrate ingredients into the mixer and fully mix and stir evenly;

[0058] Step 4, after mixing and stirring evenly, the ingredients are transported to the extruder through the delivery pipe, wherein the temperatures of the first zone, the second zone, the third zone, the fourth zone, the fifth zone, and the sixth zone of the extruder are respectively 60°C, 70°C, 80°C, 90°C, 95°C, 105°C, extruded into granules through an extruder;

[0059] Step 5, and then melt the extruded particles by heating up to 160°C through a plastic su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Operating temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap