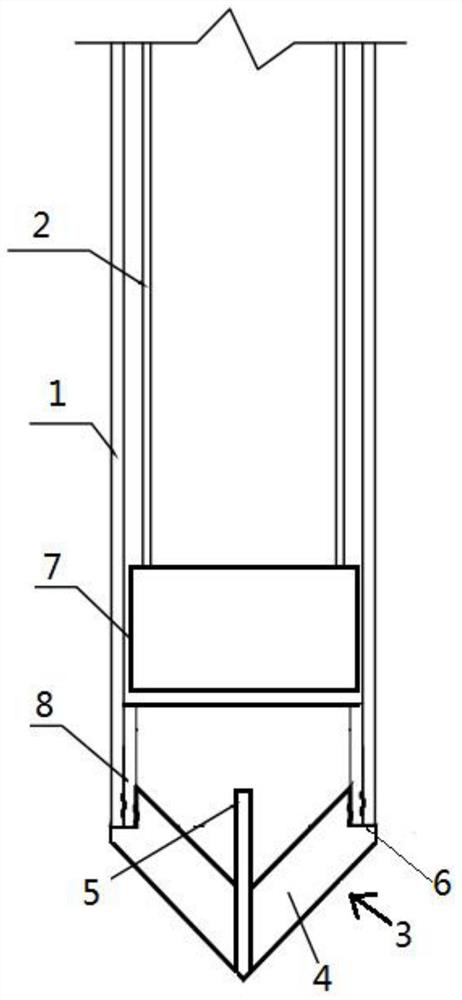

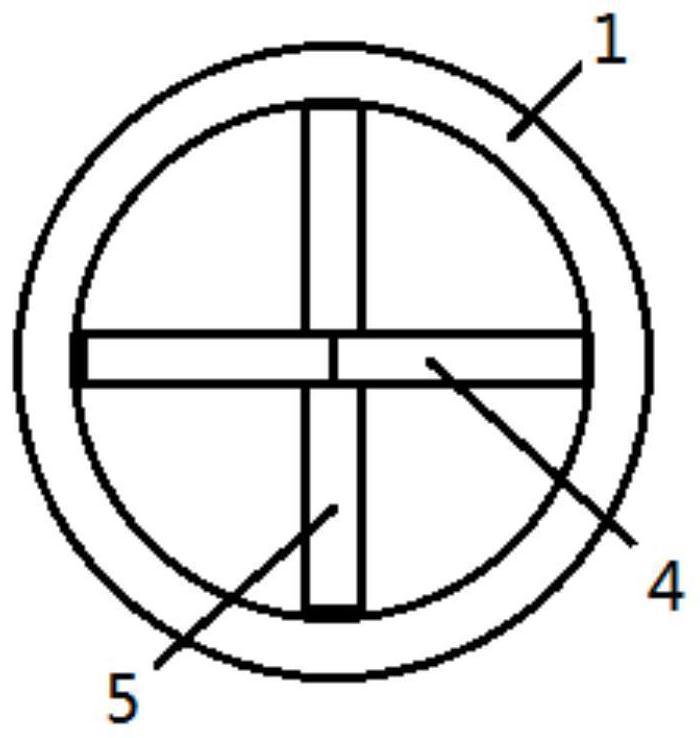

Diameter expanding equipment of cast-in-place concrete pile and construction method of cast-in-place concrete pile

A construction method and concrete technology, applied in drilling equipment and methods, drilling equipment, earth drilling and mining, etc., can solve the problems of low construction efficiency and poor soil-breaking ability, and achieve both soil-breaking ability, increased soil-breaking area, easy soil-breaking and The effect of immersed tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0034] The invention provides a construction method of concrete pouring pile, comprising the following steps:

[0035] a. using the diameter-expanding equipment described in the above-mentioned embodiment 1 to form a hole at the pile position, and sink to the first diameter-expanding position;

[0036] b. pouring flow-plastic concrete at the first diameter-expanding position, and applying a vertical downward force to the flow-plastic-shape concrete at the first diameter-expanding position by operating the diameter-expanding device, Radially extruding and expanding the flow-plastic concrete to form a first diameter-expanding structure;

[0037] c. Using the expansion device to apply a downward force to the flow-plastic concrete at the first expansion position, and to penetrate the flow-plastic concrete while radially expanding the flow-plastic concrete flow plastic concrete body;

[0038] d. sinking the expanding device downward to the second expanding position;

[0039] e. Po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com