Cleaning system of shell and tube heat exchanger and control method of cleaning system

A technology of shell-and-tube heat exchangers and cleaning systems, which is applied in cleaning heat transfer devices, lighting and heating equipment, and non-rotating equipment cleaning, etc., which can solve problems such as troublesome operation and untimely cleaning, and avoid cumbersome operations, Judgment results are accurate and avoid inaccurate judgments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

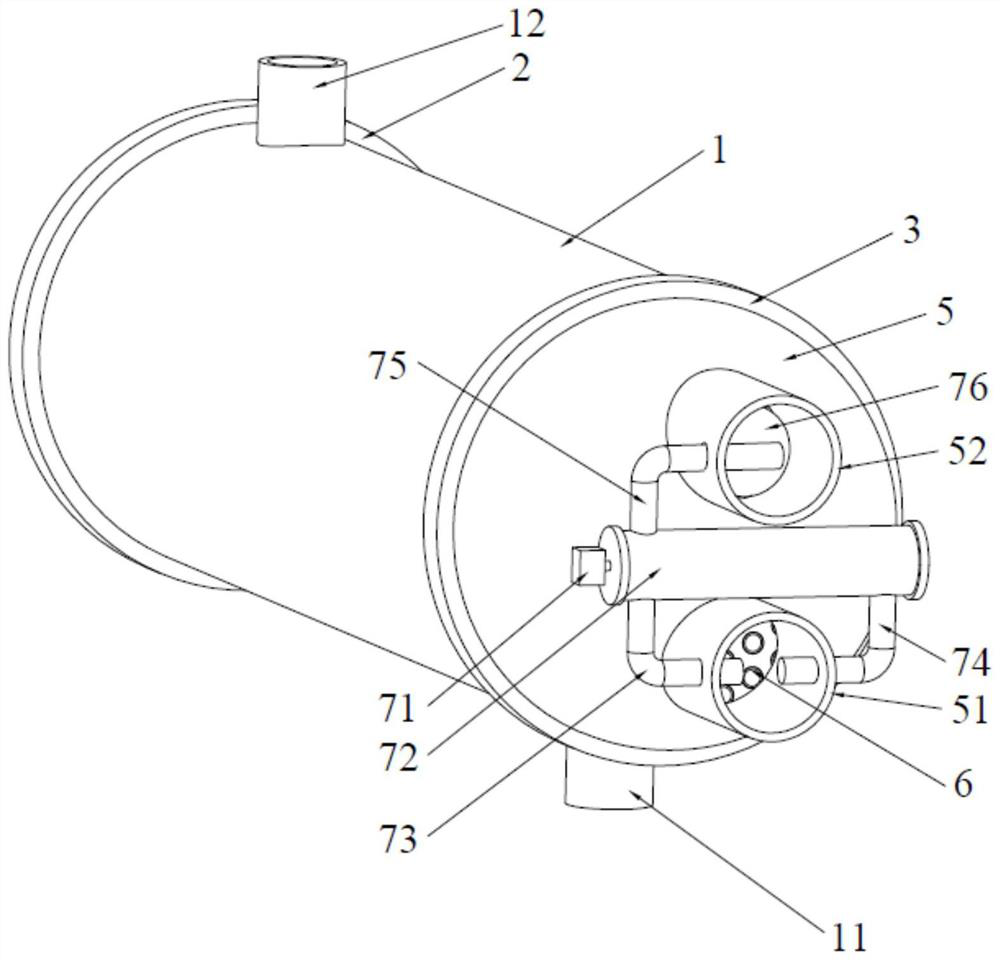

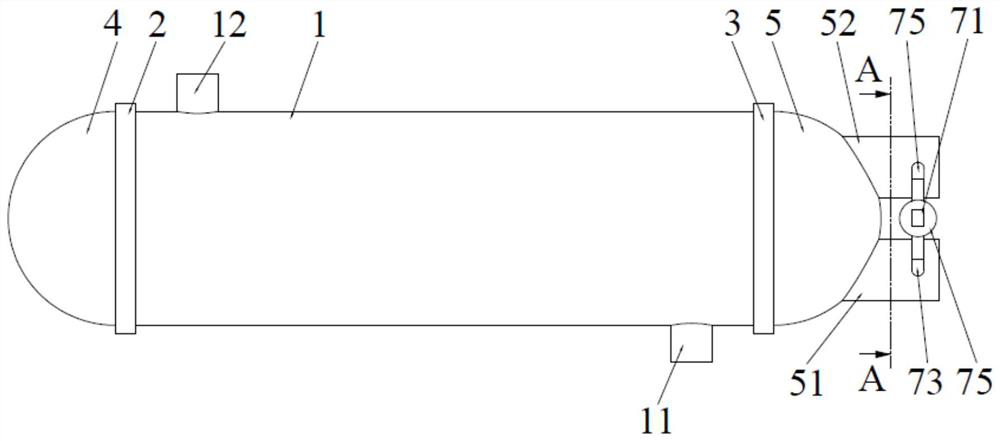

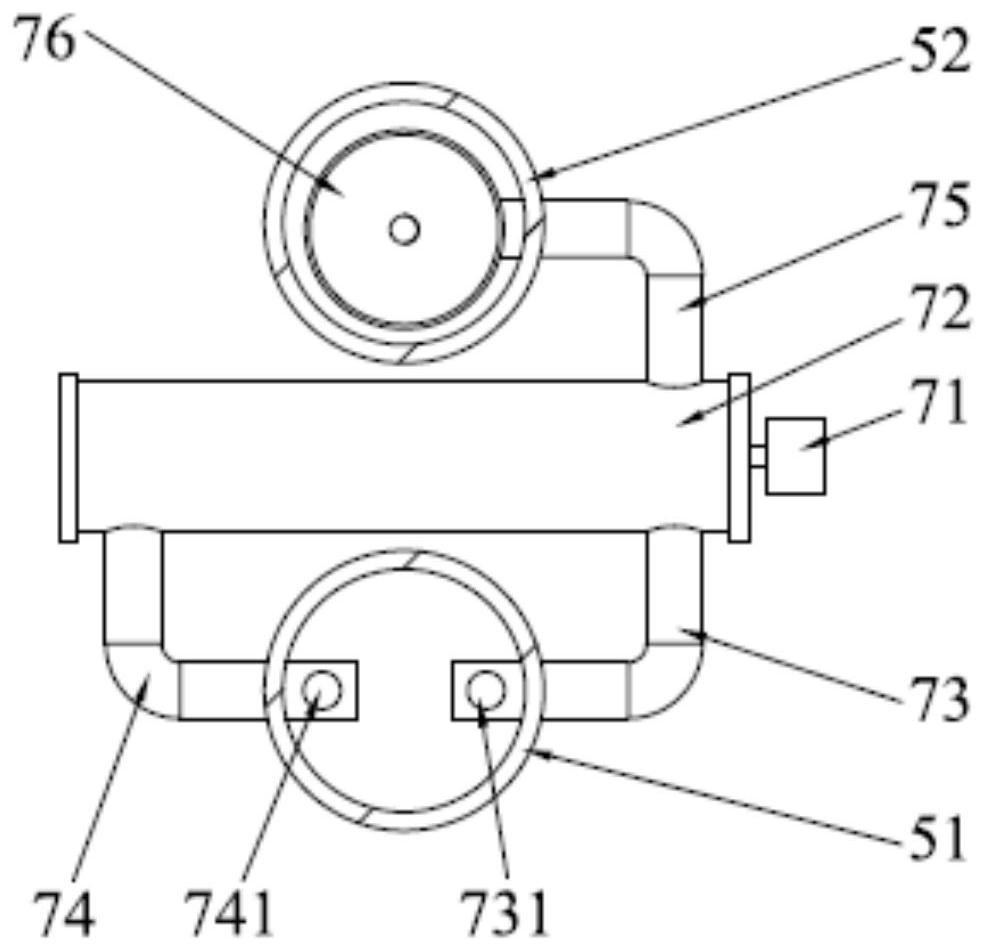

[0026] First of all, those skilled in the art should understand that the embodiments described below are only used to explain the technical principle of the present invention, and are not intended to limit the protection scope of the present invention. For example, although the present invention is described in conjunction with the shell-and-tube heat exchanger of a chiller, this does not limit the scope of protection of the present invention, and those skilled in the art can adjust it as needed to suit specific applications , For example, the shell-and-tube heat exchanger cleaning system and its control method of the present invention are also applicable to other water-cooled shell-and-tube heat exchangers, such as water-cooled shell-and-tube heat exchangers used for cooling in chemical reaction sites. The adjustment to the specific type of the application object does not constitute a limitation of the present invention, and should be limited within the protection scope of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com