Device for measuring permeability of filter

A technology for measuring devices and permeability, which is applied in the direction of measuring devices, permeability/surface area analysis, instruments, etc., can solve problems such as insufficient accuracy, poor stability of air flow meters, and insufficient stability of air source pressure, etc., to improve stability, Improve the reliability of data and the effect of high promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

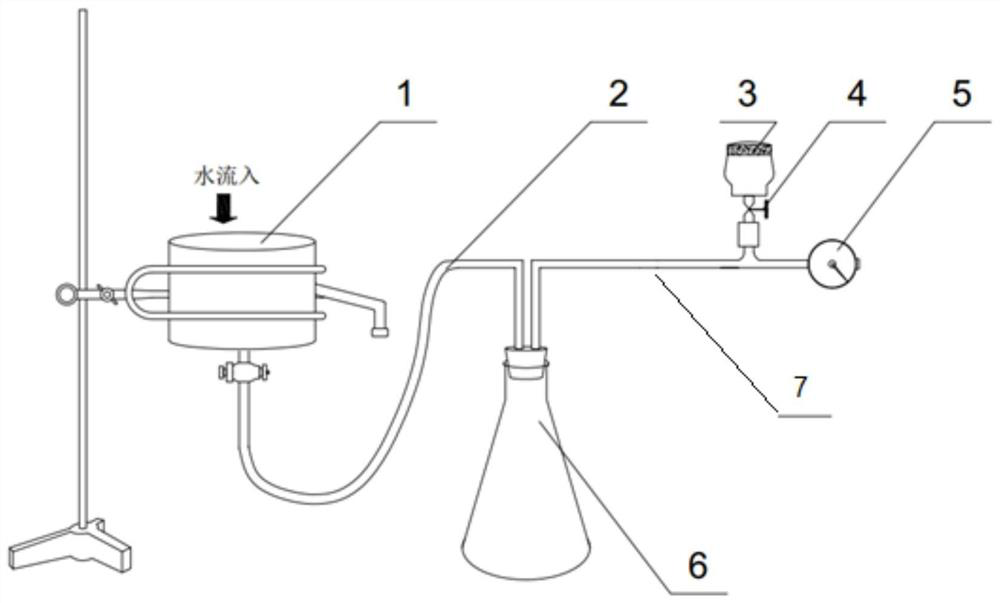

[0018] The device includes a constant current device 1 , a constant current device connecting pipe 2 , a pressure stabilizing tank 6 , a pressure gauge 4 , a valve 5 , a sample container 3 , and a sample connecting pipe 7 .

[0019] The constant current device of the present invention is a cup body made of glass, with two high and low openings on the side. The lower opening is connected to the connecting pipe of the constant current device. During the test, a steady water flow is injected into the constant flow device, and the overflow water flows out through the overflow port.

[0020] The connecting tube of the current regulator is made of glass, and a set of devices is equipped with multiple connecting tubes of the current regulator with different heights. The pressure stabilizing tanks are all sealed connections.

[0021] The pressure-stabilizing tank is made of glass, and there is a sealing cover plate on the upper part. There are two connecting holes on the cover plate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com