High-energy-efficiency milling error dynamic distribution characteristic identification method

A milling and error dynamic technology, applied in special data processing applications, complex mathematical operations, geometric CAD, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

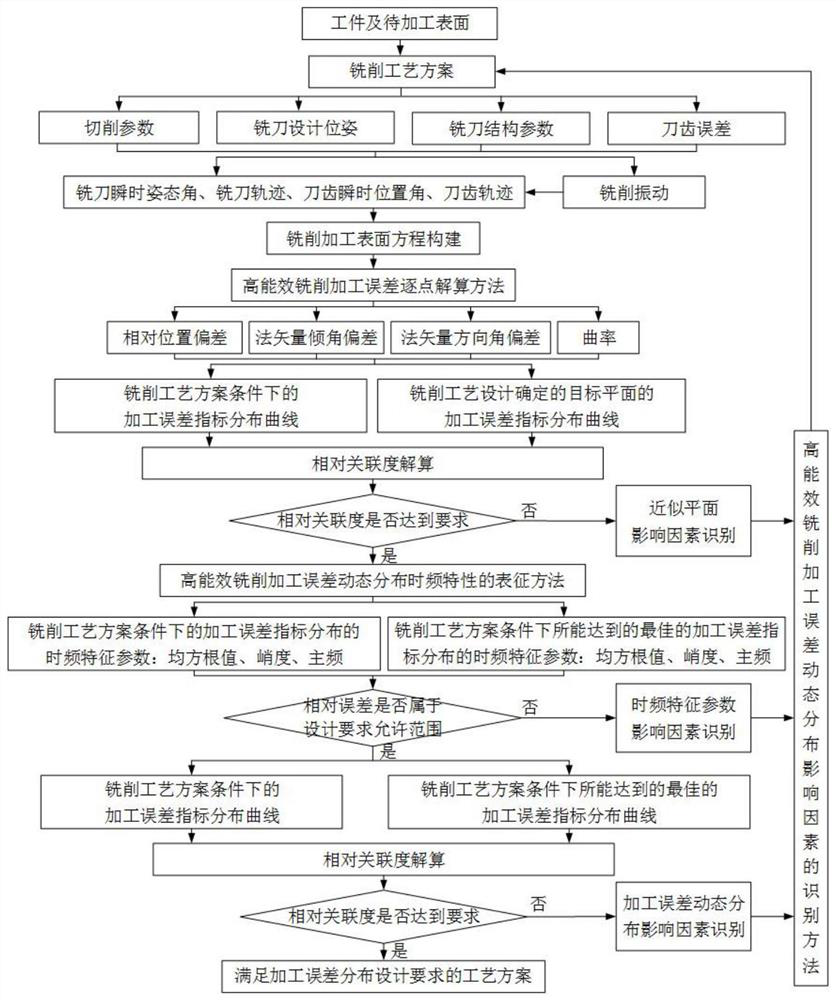

[0105] Specific implementation mode one: combine figure 1 This embodiment is described. The method for identifying the dynamic distribution characteristics of energy-efficient milling errors in this embodiment can identify the dynamic distribution characteristics of milling errors, which can provide a more convenient method for realizing the precise control of the surface formation process of high-energy-efficiency milling. Most of the existing milling error identification methods focus on the overall level of the milling surface geometric parameters and the degree of deviation from the design index. Compared with the existing methods for identifying the overall level of milling processing errors, the present invention uses a time-frequency analysis method to quantitatively describe the dynamic distribution characteristics of milling processing errors.

[0106] Using the change characteristics of the instantaneous cutting behavior of adjacent teeth under the action of the toot...

specific Embodiment approach 2

[0128] Specific implementation mode two: combination Figure 1-Figure 4 Describe this embodiment, the energy-efficient milling error dynamic distribution characteristic identification method of this embodiment, and the high-energy-efficiency milling error point-by-point solution method. The specific calculation steps are as follows:

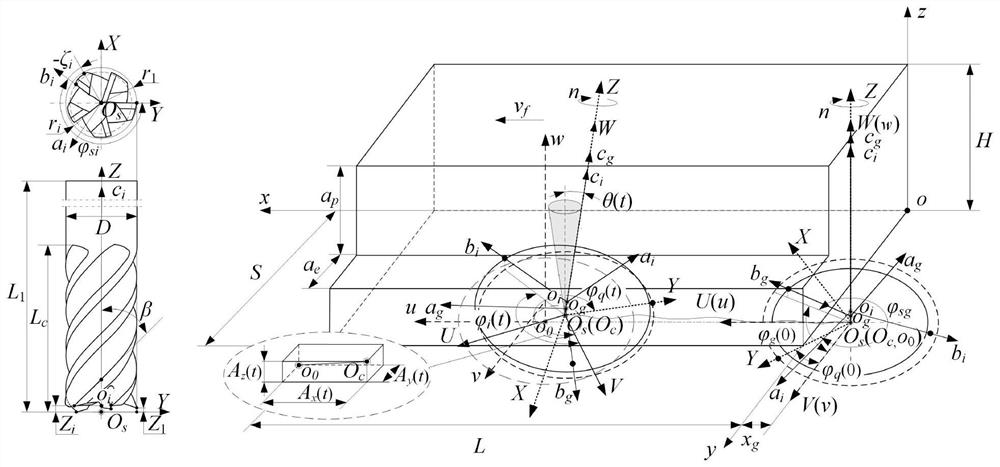

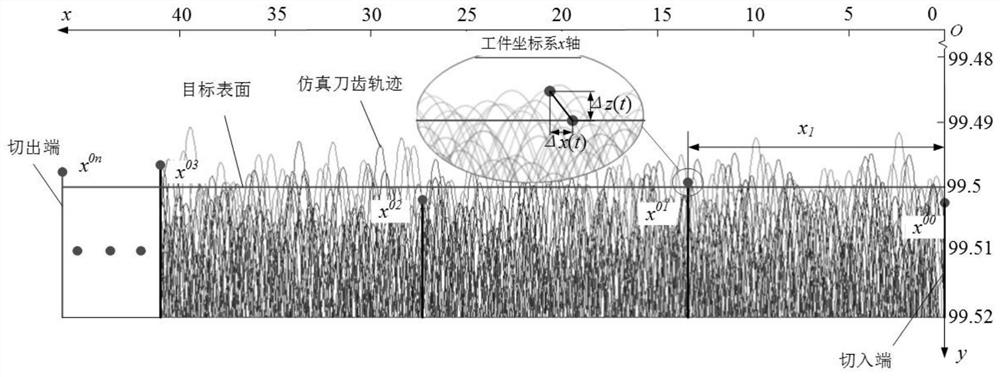

[0129] The instantaneous cutting behavior of high-energy-efficiency milling cutters and their teeth directly affects the formation process of the milled surface, thereby affecting the distribution of milling errors. In the existing milling machining error measurement and characterization, the error maximum method is mainly used to judge the overall deviation level of the milling surface geometric parameters, ignoring the time-frequency localization characteristics of the relative position vector of the remaining milling surface feature points between the teeth. In the technical feature, the relative position vector of the milling surface is calcu...

specific Embodiment approach 3

[0159] Specific implementation mode three: combination Figure 1-Figure 7 Describe this embodiment, the method for identifying the dynamic distribution characteristics of high-energy-efficiency milling processing errors in this embodiment, and the characterization method for the time-frequency characteristics of dynamic distribution of high-energy-efficiency milling processing errors. The specific calculation steps are as follows:

[0160] The time-frequency analysis method plays an important role in quantitatively describing the diversity of milling errors. The existing studies on the dynamic distribution of milling machining errors have neglected the differences in the instantaneous cutting behavior of each tooth and the time-frequency characteristic changes of the position vectors of the residual milling surface feature points between the teeth. In the present invention, the time-frequency characteristic of the milling processing error index is used to characterize the dyna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com