Novel traction motor connecting line structure and binding method

A traction motor and wiring technology, applied in the field of electric motors, can solve the problems of poor impact resistance, difficult wiring binding, reduced wiring weight and impact resistance, etc., to achieve strong impact resistance, low wiring weight, and reduced wiring. Effects of Axial Space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In view of the problems of large axial size and weak motor performance in the current in-line structure of traction motors, it is difficult to obtain the best of both worlds in terms of the axial size of the motor and the performance of the motor. This embodiment proposes an optimized and improved solution to solve the problems existing in the prior art.

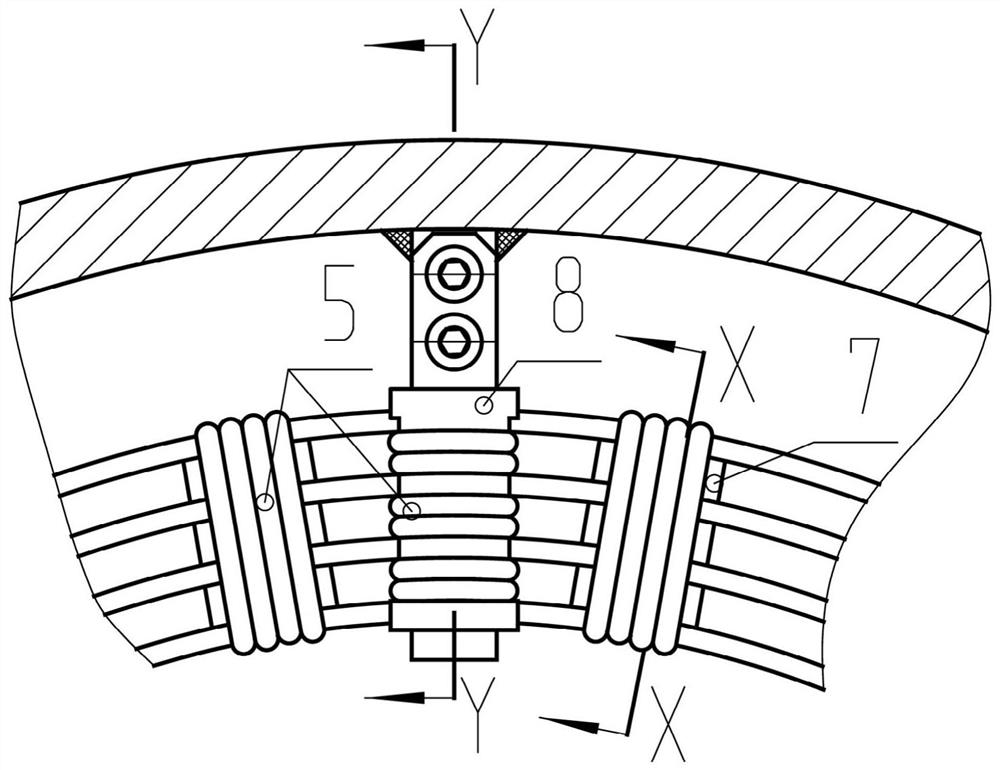

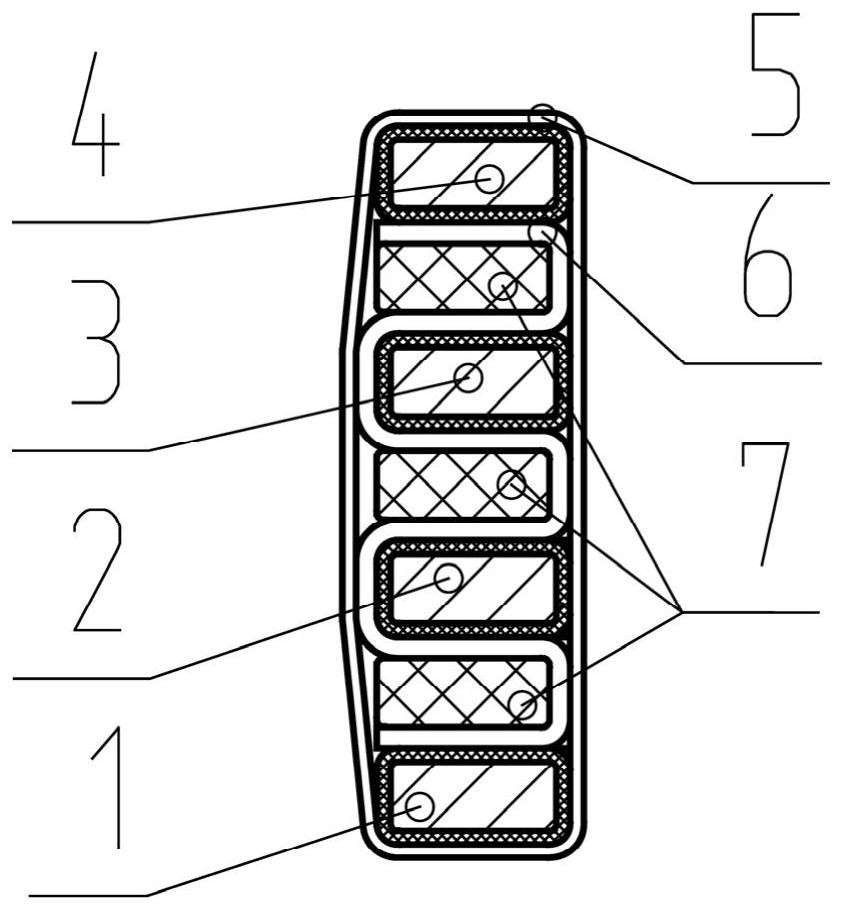

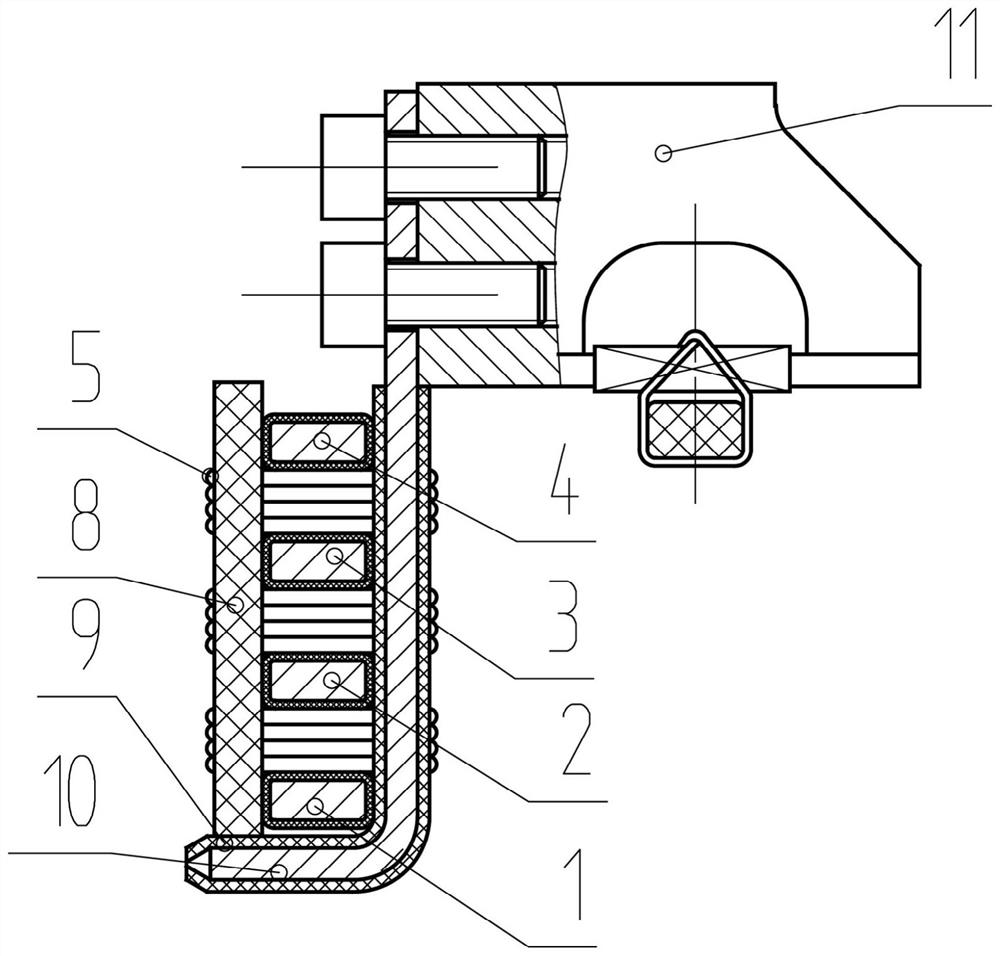

[0038] Specifically, such as Figure 1 ~ Figure 3 As shown, this embodiment discloses a new type of traction motor wiring structure, including several confluence rings coaxially arranged on the same plane, and several confluence rings are connected as a whole through several first binding structures arranged along the circumference, and It is fixed by several second binding structures arranged along the circumference; the first binding structure includes a first insulating member 7 arranged between two adjacent collector rings, and a plugging felt is also arranged between the first insulating member 7 and the collecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com