Pull-type garlic planting machine

A traction-type garlic machine technology, applied in potato planters, planting methods, agriculture, etc., can solve problems such as low efficiency, inability to ensure that all garlic buds are basically upward, and manual planting is labor-intensive, so as to increase production , improve seeding quality, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

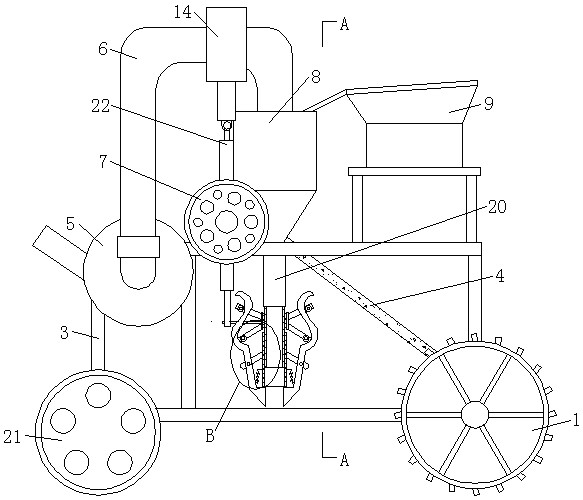

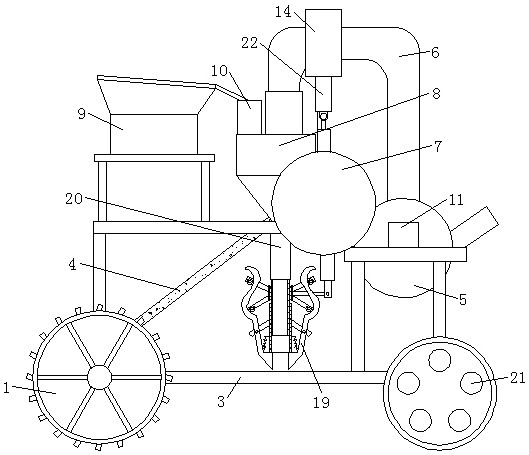

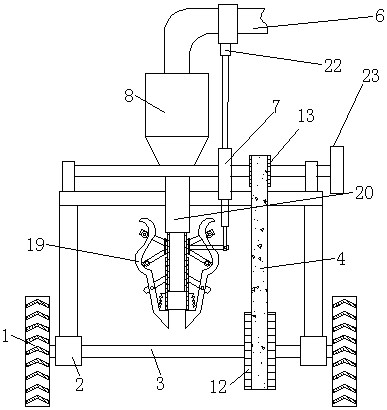

[0022] refer to Figure 1-7 As shown, the present embodiment is described with the structure of sowing a row of garlic seeds. There is a frame 3, the front bottom of the frame 3 supports the front wheel shaft by the sliding sleeve bearing 2, and the two ends of the front wheel shaft are fixed with the front ground wheel 21; or the front bottom of the frame 3 is fixed with the front wheel shaft, the two ends of the front wheel shaft Front ground wheel 21 is supported by sliding sleeve bearing 2, that is to say, two freely rotatable front ground wheels 21 are set to support the front part of frame 3; the rear part of frame 3 is provided with rotatable ground wheel shaft, and The rear ground wheel 1 is fixed at both ends, and the outer surface of the rear ground wheel 1 is welded with a plurality of antiskid teeth, and the antiskid teeth are evenly distributed on the outer surface of the rear ground wheel 1; a rotatable transmission shaft is arranged on the frame 3, and the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com