Zero-lactose single cream and preparation method thereof

A lactose-free, creamy technology, applied to cream preparations, dairy products, milk preparations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

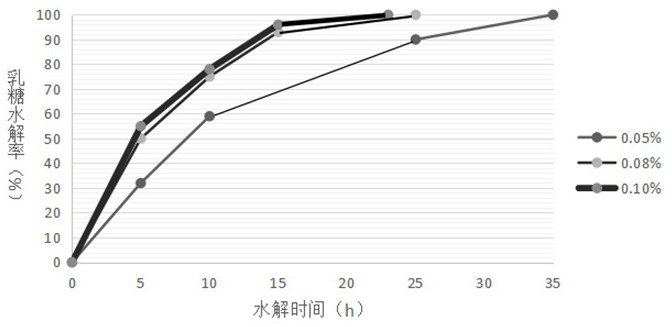

[0016] Embodiment 1: long-term hydrolysis at low temperature

[0017] A preparation method of lactose-free cream, comprising the following steps:

[0018] 1.1) Raw milk is inspected and passed into the milk storage tank, and the temperature is maintained at 6°C;

[0019] 1.2) Add ß-galactosidase to raw milk at an amount of 0.1%, stir evenly; and hydrolyze at 6°C for 24-35 hours;

[0020] 1.3) Re-sampling for testing requires that the lactose hydrolysis rate is above 98% and the lactose residue is below 0.3%, to obtain lactose-free milk;

[0021] 1.4) Separating and cooling the lactose-free milk obtained to produce lactose-free cream; and sampling and testing to meet the national standard zero-lactose requirements.

[0022] Such as figure 1 As shown, the lactose detection results of the cream prepared by the preparation method of Example 1: the hydrolysis rate reaches 99.1%, and the actual detection average value of lactose is 0.2%.

Embodiment 2

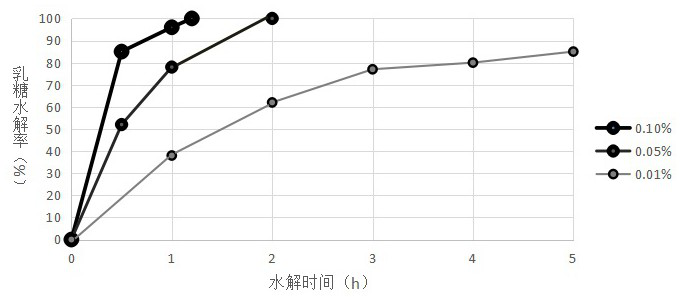

[0023] Embodiment 2: high temperature short time hydrolysis

[0024] A preparation method of lactose-free cream, comprising the following steps:

[0025] 2.1) The raw milk is inspected and passed into the milk storage tank, and the temperature is maintained at 6°C;

[0026] 2.2) Raw milk is pasteurized at 65°C~85°C / 15 seconds, then cooled to 40°C;

[0027] 2.3) Add ß-galactosidase to the raw milk, the addition amount is 0.05%, stir evenly, and hydrolyze at 40°C for 2-4 hours;

[0028] 2.4) Re-sampling and testing require that the lactose hydrolysis rate is above 98% and the lactose residue is below 0.3%, to obtain lactose-free milk;

[0029] 2.5) Separating and cooling the obtained lactose-free milk to obtain lactose-free cream; and sampling and testing to meet the national standard zero-lactose requirements.

[0030] Such as figure 2 As shown, the lactose detection results of the cream prepared by the preparation method of Example 2: the hydrolysis rate reaches 99.1%, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com