Water pan special-shaped connecting pipe forming device

A technology of tube forming and water receiving tray, which is applied in the field of special-shaped connecting tube forming device for water receiving tray, can solve the problems of occupying a large space, high equipment procurement cost, injury to staff, etc. The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

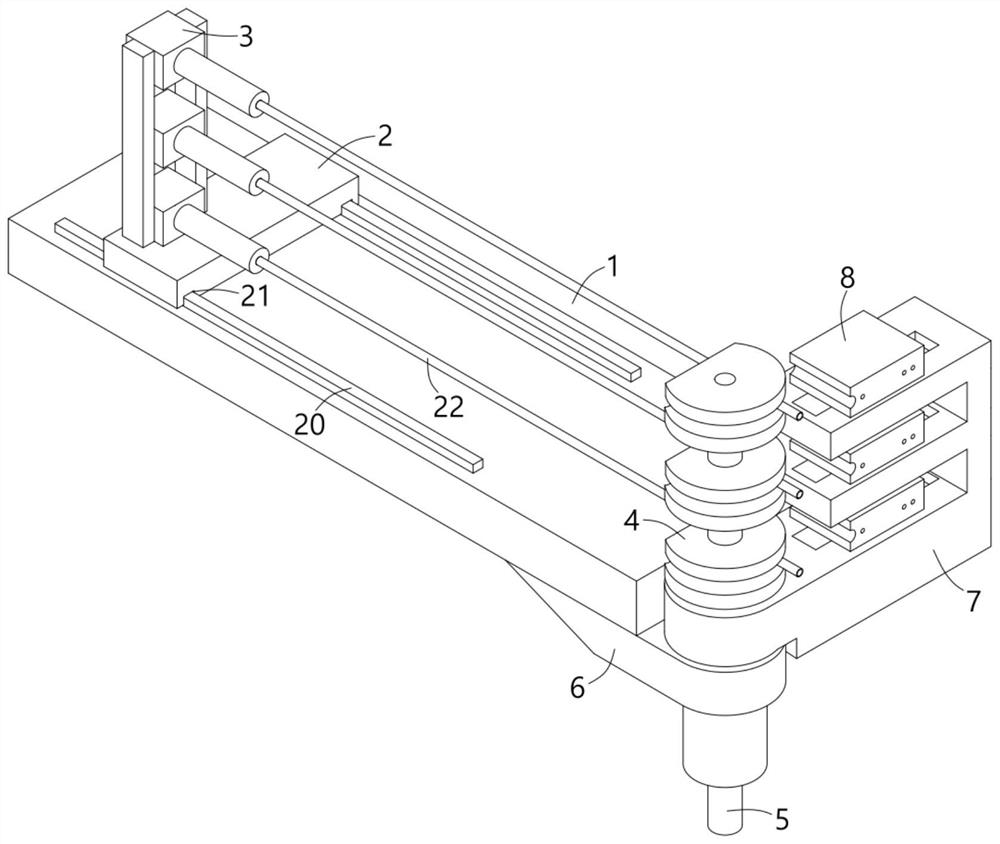

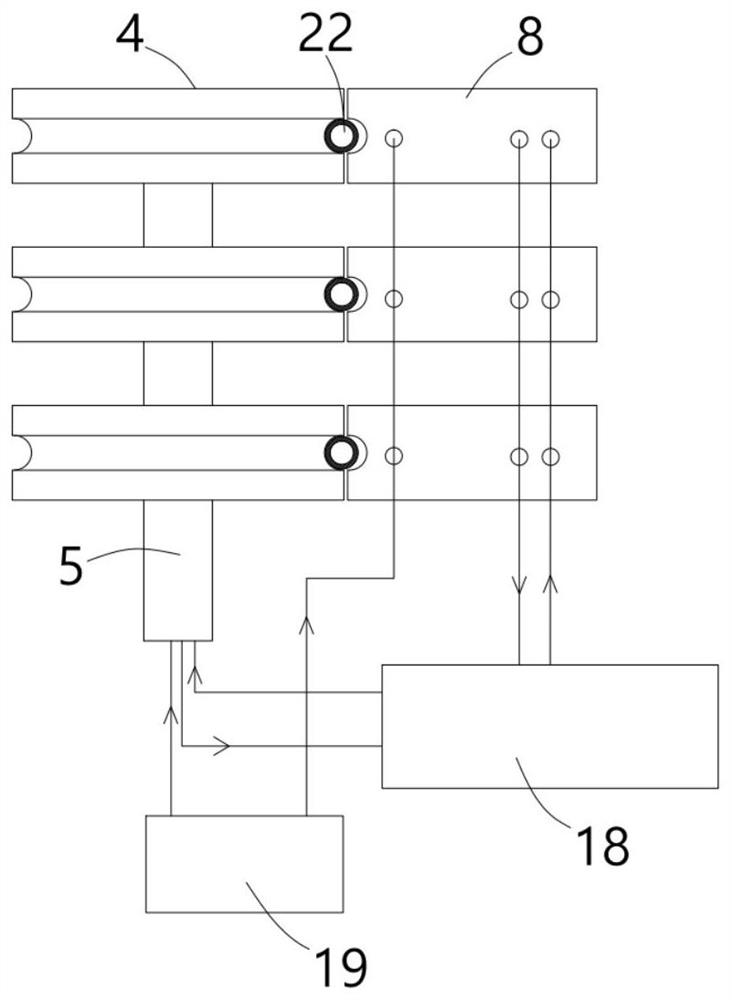

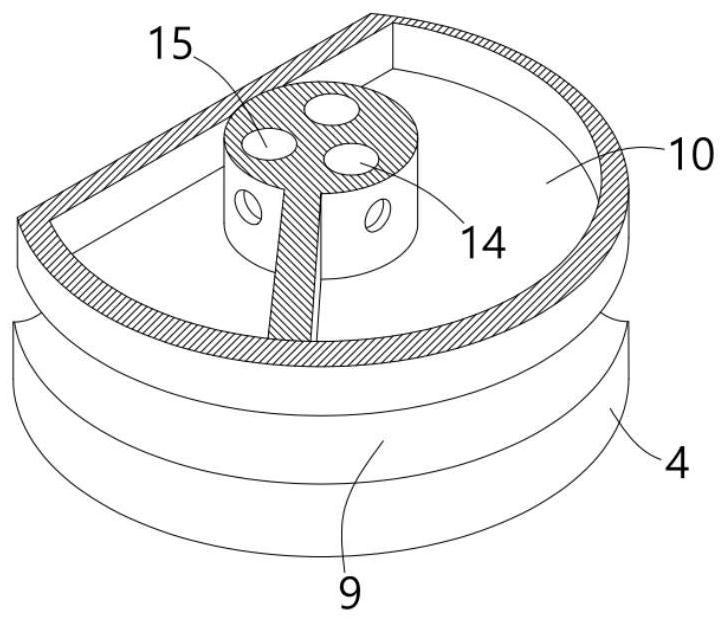

[0026] see Figure 1-7 , the present invention provides a technical solution:

[0027] A forming device for special-shaped connecting pipes of a water tray, comprising a pipe bending machine 1, a translation seat 2 is arranged on one side of the pipe bending machine 1, and a plurality of pipe feeding mechanisms 3 are installed on the translation seat 2 evenly spaced in the vertical direction, and the pipe bending machine 1. A number of special-shaped pipe bending rollers 4 are movable on one side, and several special-shaped pipe bending rollers 4 are fixedly installed on the same rotating shaft 5. Bend pipe seat 7, on the pipe bend seat 7, runs through and is provided with the through hole for rotating shaft 5 to insert, and pipe bend seat 7 carries out circular motion along rotating shaft 5 under the drive of pipe bending motor, and the number and the number of flexible pipe bend seat 7 are provided with The special-shaped pipe bending rollers 4 are consistent and one-to-one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com