Screwdriver

A screwdriver and helical wheel technology, applied to screwdrivers, manufacturing tools, etc., can solve problems such as low efficiency and inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

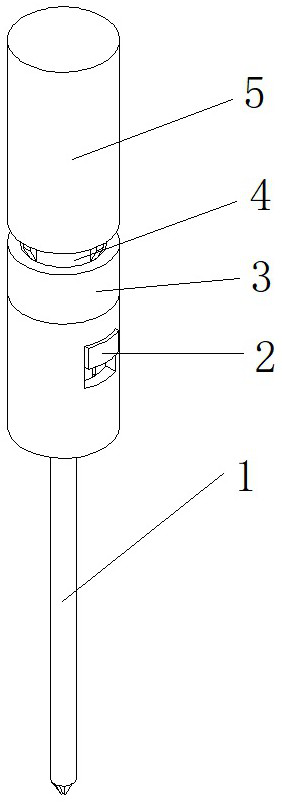

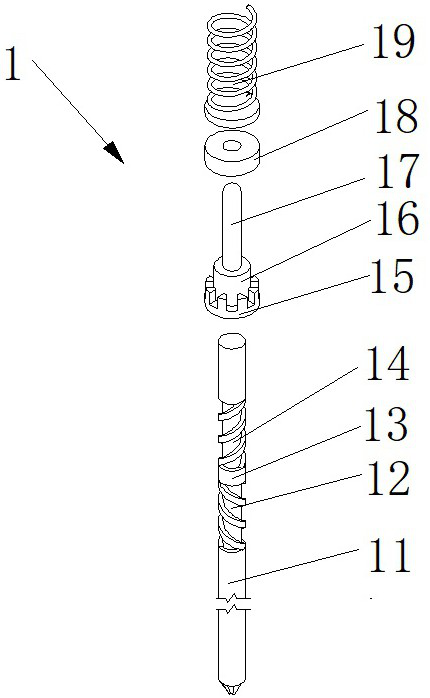

[0031] A screwdriver, comprising a shaft barrel 4, a wheel train 2 installed in the shaft barrel 4, a shaft system 1 installed on the wheel train 2, a dial ring 3 set outside the shaft barrel 4, and a casing fixed outside the shaft barrel 4 5.

[0032] The shaft cylinder 4 includes a cylindrical cylinder body 41, a screw wheel mounting nail 42 installed on the cylinder body 41, a 7-shaped stop claw 43 fixedly installed on the lower end of the cylinder body 41, and fixedly arranged in the cylinder body 41. The retarder cylinder 44.

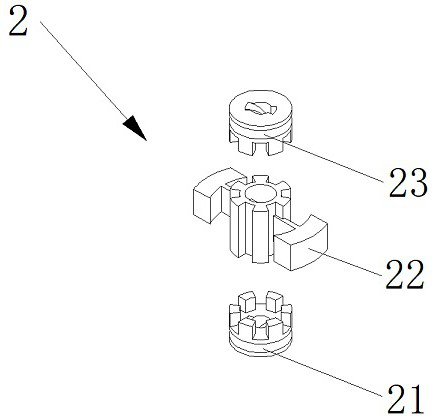

[0033] The gear train 2 includes a lower helical wheel 21 and an upper helical wheel 23 mounted on the lower end and upper end of the shafting 1 respectively, and a clutch spline sleeve 22 fitted on the shafting;

[0034] The inner sides of the lower h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com