An injection mold for instrument panel

A technology for injection molds and dashboards, which is applied to household appliances, other household appliances, applications, etc., can solve the problems of difficult to directly remove the reinforcing ribs and difficult to pick up the product, so as to achieve independent adjustment control, reduce the difficulty of picking up, and simplify the The effect of mold structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The following is combined with the attached Figure 1-15 Further elaboration of this application.

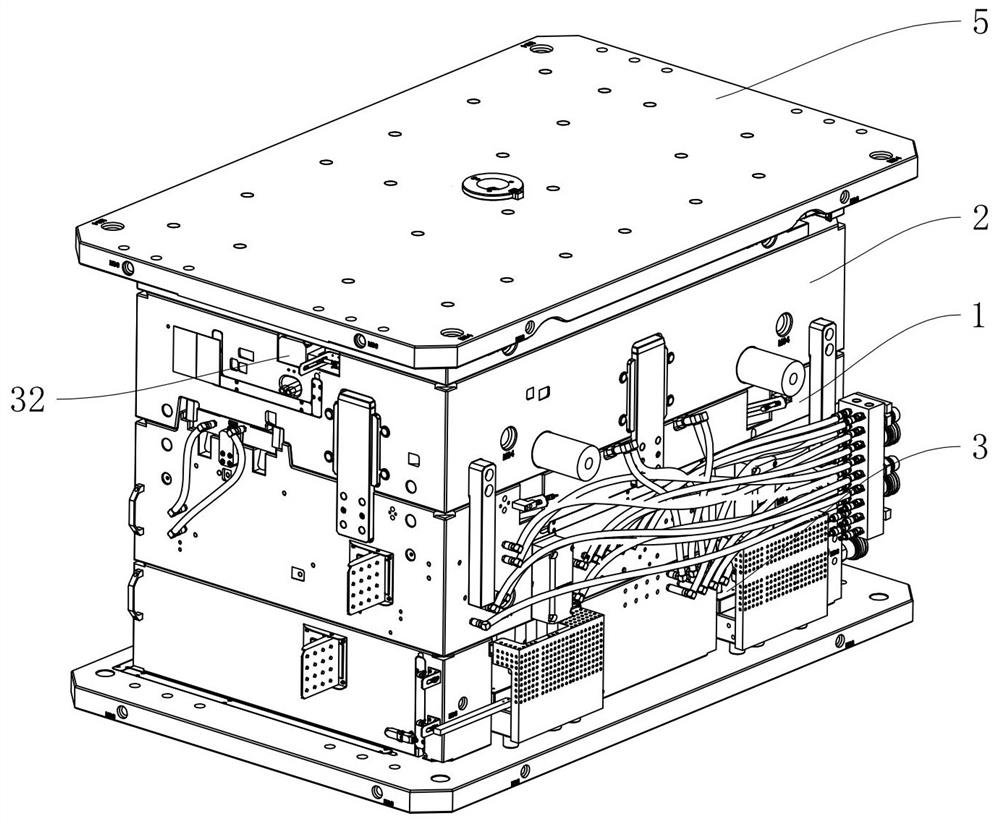

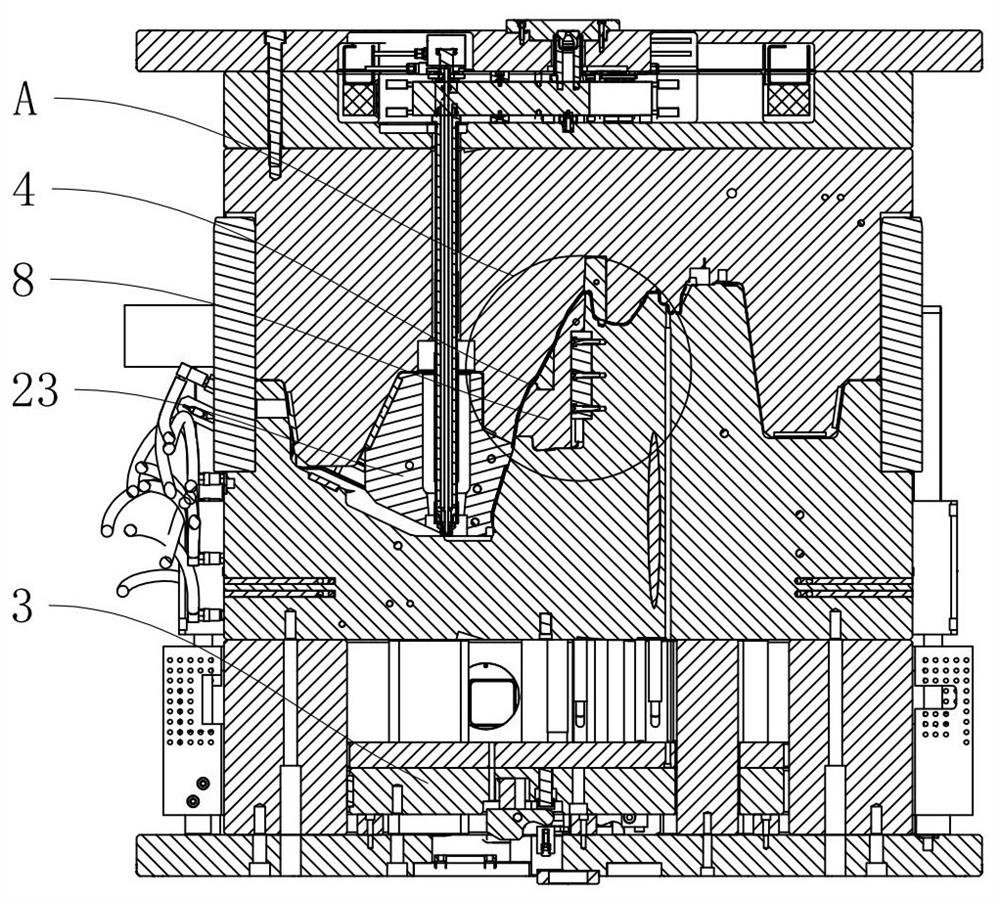

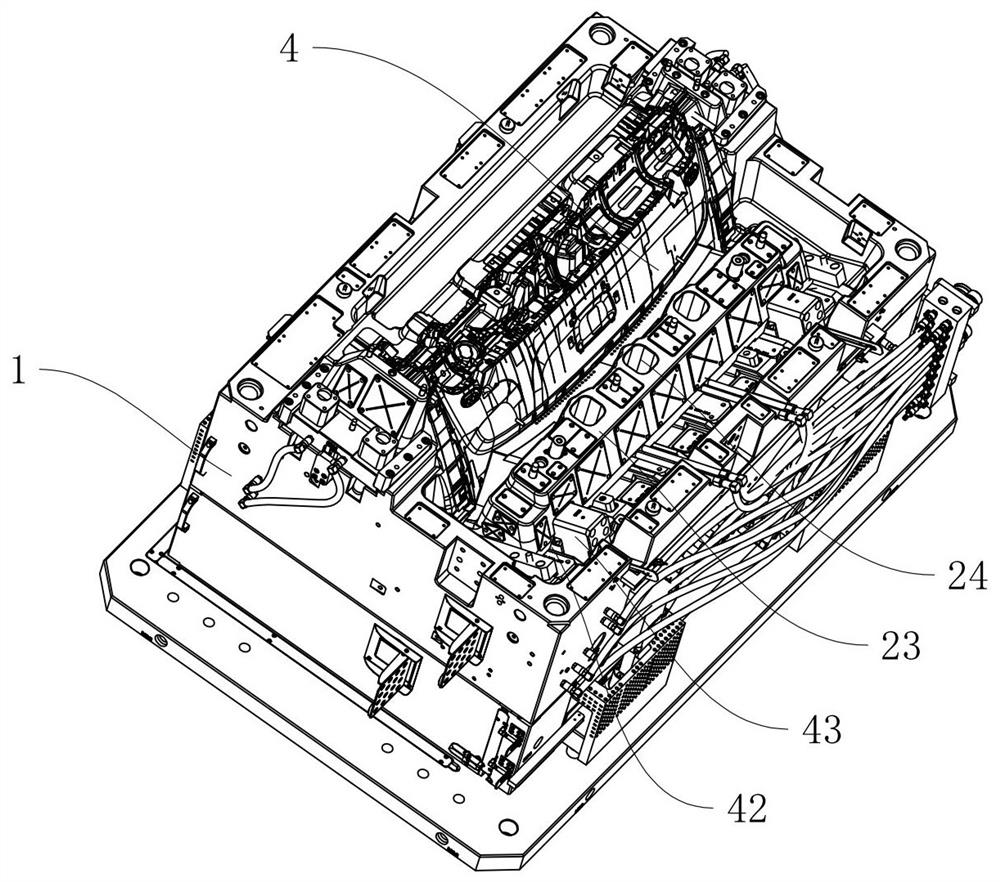

[0052] Embodiments of the present application disclose an injection mold for the dashboard. Reference Figure 1 and Figure 2 The injection mold for the dashboard includes the injection assembly 5, the cavity plate 2, the core plate 1, and the ejection component 3 from top to bottom. Wherein between the cavity plate 2 and the core plate 1 to form a cavity for forming the dashboard 4, on the ejection component 3 is provided for forming the dashboard part of the board surface and for the dashboard out of the cavity 4 of the straight top block 8, on the core plate 1 is provided for forming the dashboard part of the board surface of the forming slider 23, on the cavity plate 2 is provided for forming the shape of the through hole in the dashboard core slider 32.

[0053] Referring to FIG., 3, there are two push cylinders 42 on the core plate 1, the push cylinder 42 is provided on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com