An improved casting sand box

An improved mold and sand box technology, applied in the field of sand casting, can solve the problems of increasing the workload of employees, increasing the difficulty of picking up parts, and rapidly cooling the molten metal, so as to reduce the difficulty of picking up parts, increase the difficulty of picking up parts, and avoid sticking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

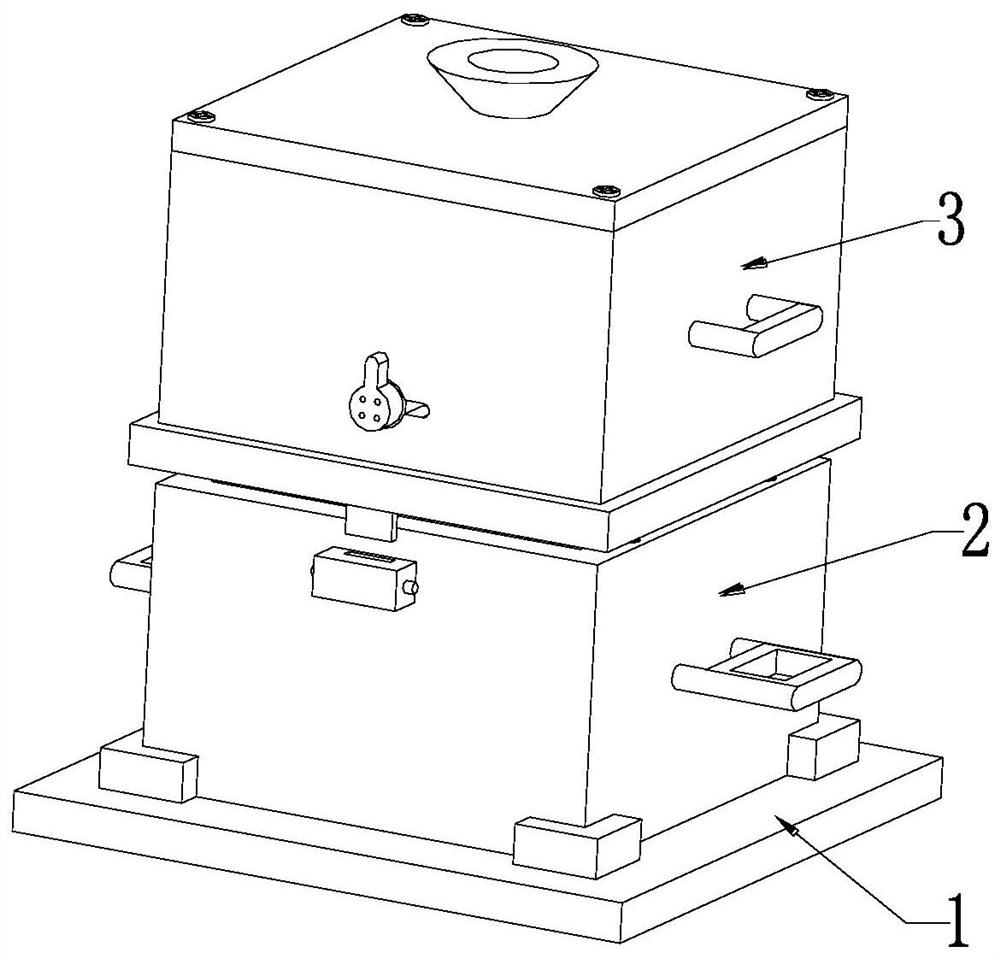

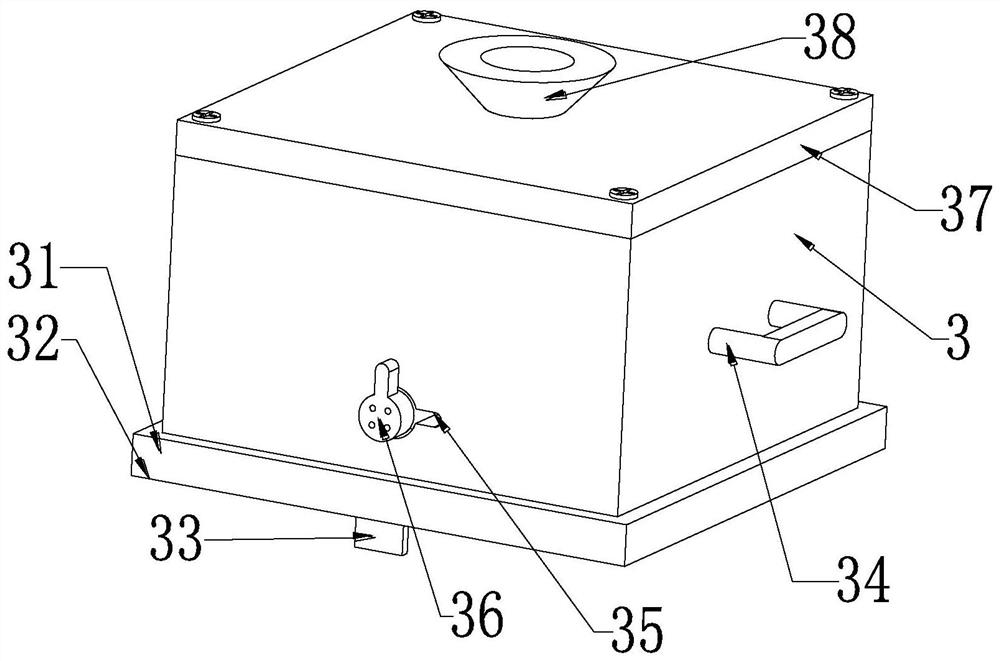

[0028] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 9 , to further elaborate the present invention.

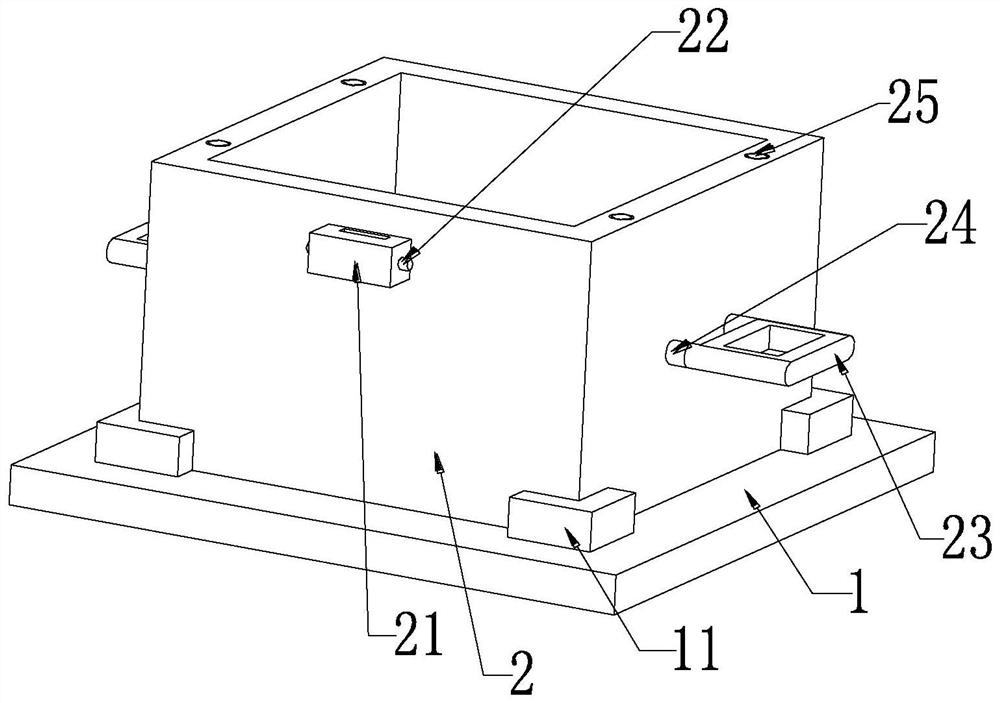

[0029] An improved casting sand box, comprising an installation base 1, a lower sand box 2 and an upper sand box 3, the upper end of the installation base 1 is provided with a lower sand box 2, and the upper end of the lower sand box 2 is provided with an upper sand box 3 for mutual use, in:

[0030] 30. The lower sand box 2 includes an alignment box 21, a locking mechanism 22, a handle ring 23, a connecting column 24 and a lifting mechanism 25. The alignment box 21 is symmetrically installed on the front and rear ends of the lower sand box 2 by welding, The alignment box 21 is provided with a blind hole A, and the inside of the blind hole A is provided with a locking mechanism 22, and the left and right ends of the lower sand box 2 are symmetrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com