Intelligent automatic intensive warehousing system

A warehousing system and intelligent technology, applied in the direction of transportation, packaging, storage devices, etc., can solve the problems of inconvenient operation control, chaotic internal connection management, inconvenient conduction and transportation operations, etc., and achieve the effect of convenient storage work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

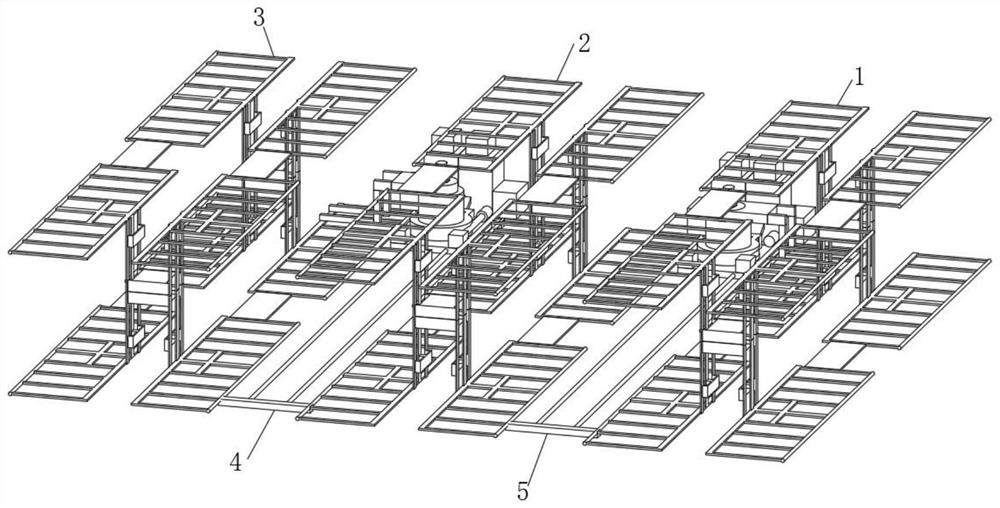

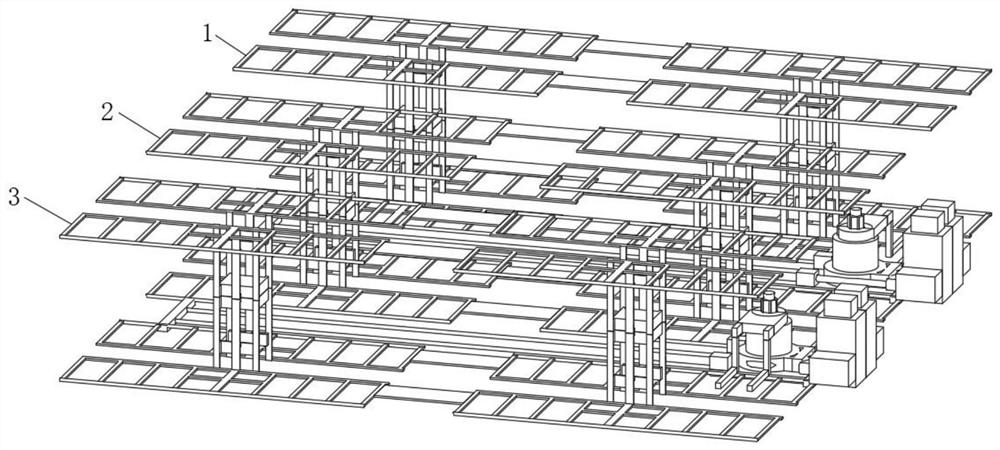

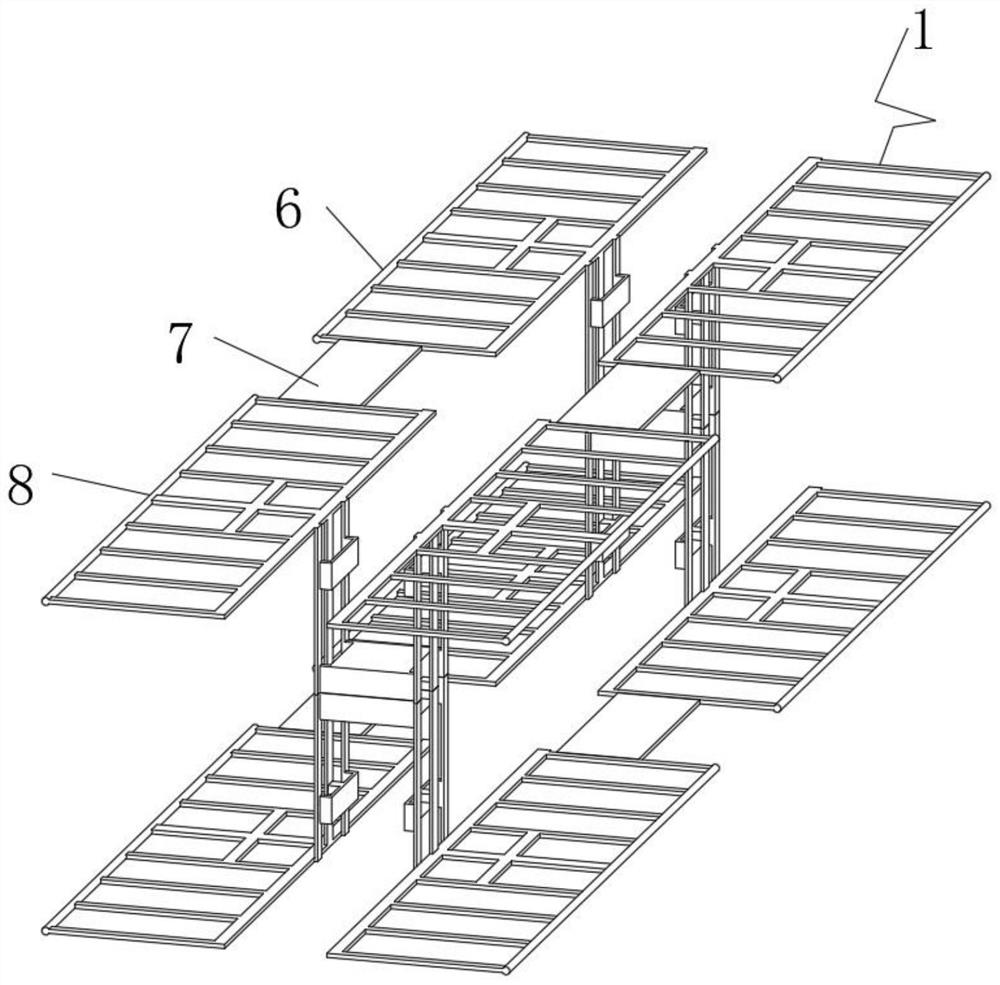

[0035] see Figure 1-7, an embodiment provided by the present invention: an intelligent automated intensive storage system, including a first placement part 1, the side end of the first placement part 1 is fixedly connected with a second transmission part 5, and the side of the second transmission part 5 The end position is fixedly connected with the second placement part 2, the side end position of the second placement part 2 is fixedly connected with the first transmission part 4, and the side end position of the first transmission part 4 is fixedly connected with the third placement part 3, through the first The structural setting of the placement part 1, the second placement part 2, the third placement part 3, the first transmission part 4 and the second transmission part 5 can help form a three-dimensional network space and better carry out integrated production connection work, Convenient for warehousing and transmission;

[0036] The first placement part 1 includes a f...

Embodiment 2

[0046] On the basis of Example 1, such as Figure 8 As shown, the top positions of the first placement part 1 , the second placement part 2 and the third placement part 3 are all fixedly connected with a protective shell frame 24 .

[0047] During the implementation of this embodiment, the protection work of the top positions of the first placement part 1, the second placement part 2 and the third placement part 3 can be realized through the connection and arrangement of the protective shell frame 24, and the barrier treatment work of the top position can be realized. And the structural setting of the protective shell frame 24 facilitates the protection of the top position, which is conducive to the protection of objects.

[0048] Working principle: The user combines and connects the first placement part 1, the second placement part 2, the third placement part 3, the first transmission part 4 and the second transmission part 5 to realize mutual installation and erection work a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com