System and method for detecting bag stacking state of bagged material loading machine

A technology of state detection and loading machine, which is applied in the direction of radio wave measurement system, conveyor, measuring device, etc., can solve the problem of code packet state without detection system, etc., and achieve good code packet effect, high economic benefit, and high precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

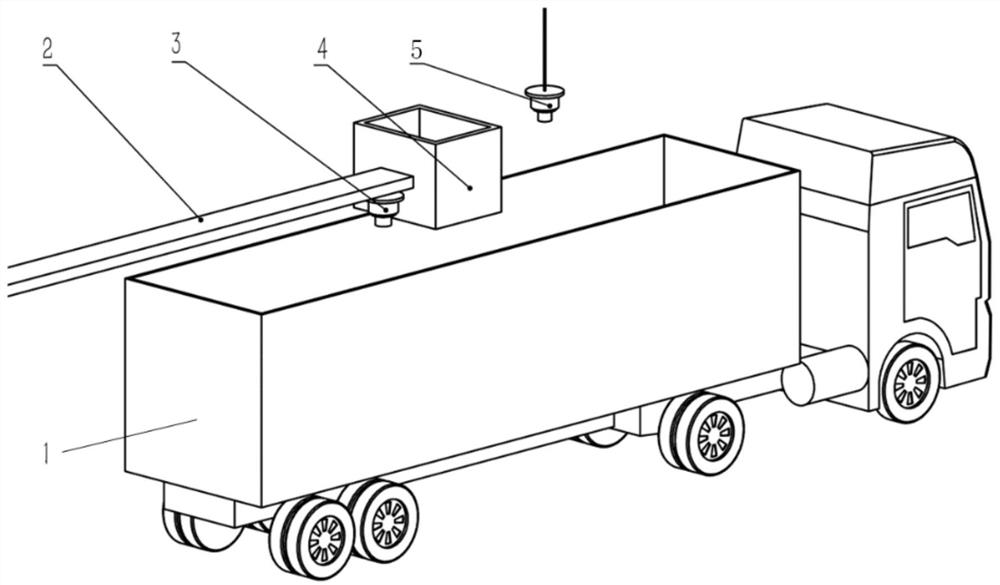

[0034] This embodiment provides a code package state detection system of a bagged material loading machine, such as figure 1 As shown, it includes a bagged material loading machine 1, an upper laser radar 5, a lower laser radar 3, and a controller. The upper laser radar 5 is arranged above the bucket of the bagged material loading machine, and the lower laser radar 3 is arranged The bottom of the stacking head 4 of the material loading machine does not affect the loading position; the controller is arranged inside the bagged material loading machine; the controller communicates with the upper laser radar 5 and the lower laser radar 3 respectively through data transmission lines. The controller of this embodiment can control the start and stop and data processing of the upper laser radar 5 and the lower laser radar 3; the main function of the upper laser radar 5 is to detect the size of the bagged material loading machine and the bagged material loading machine The edge part de...

Embodiment 2

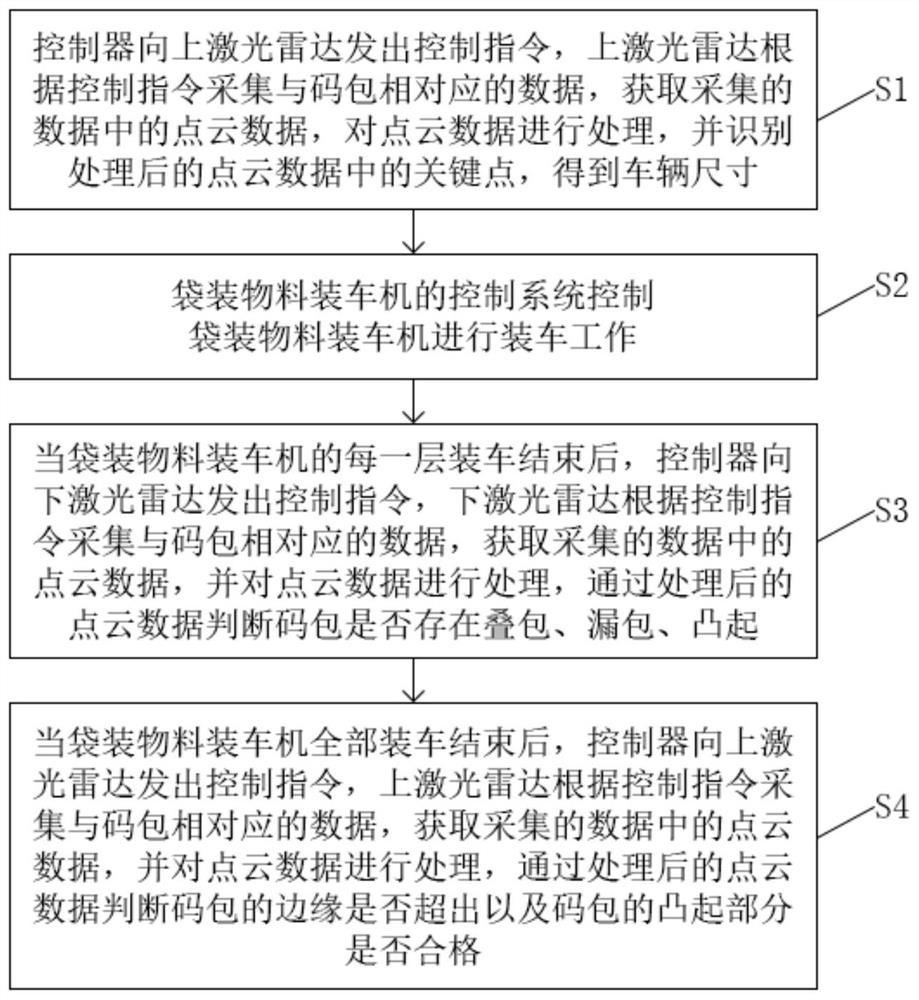

[0057] Correspondingly, there is also provided a method for detecting the status of coded bags of a bagged material loading machine, such as figure 2 shown, including:

[0058] S1. Determine whether the bagged material loader has entered the loading area. If so, the controller sends a control command to the upper laser radar, and the upper laser radar collects the data corresponding to the code package according to the control command, and obtains the point cloud data in the collected data. , process the point cloud data, and identify the key points in the processed point cloud data to obtain the vehicle size;

[0059] S2. The control system of the bagged material loading machine controls the bagged material loading machine to carry out the loading work;

[0060] S3. When the loading of each layer of the bagged material loading machine is completed, the controller sends a control command to the downward laser radar, and the downward laser radar collects the data correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com