Self-flowing energy dissipation concrete pouring method for deep foundation pit and concrete self-flowing energy dissipation structure

A concrete and deep foundation pit technology, which is applied in the direction of infrastructure engineering and construction, can solve the problems of excessive self-flowing speed of concrete, and achieve the effect of simple structure, guaranteed properties, and guaranteed construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

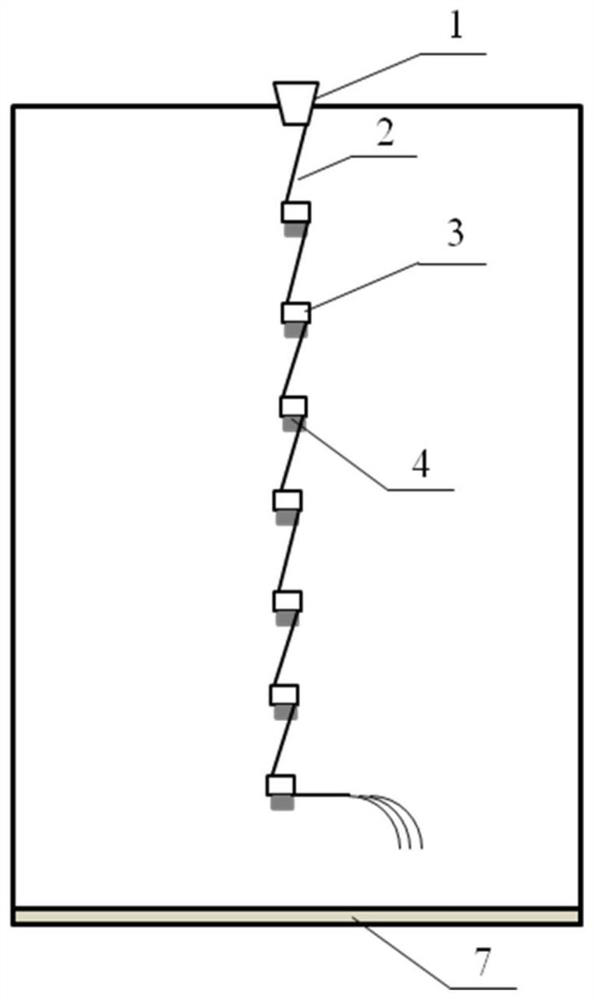

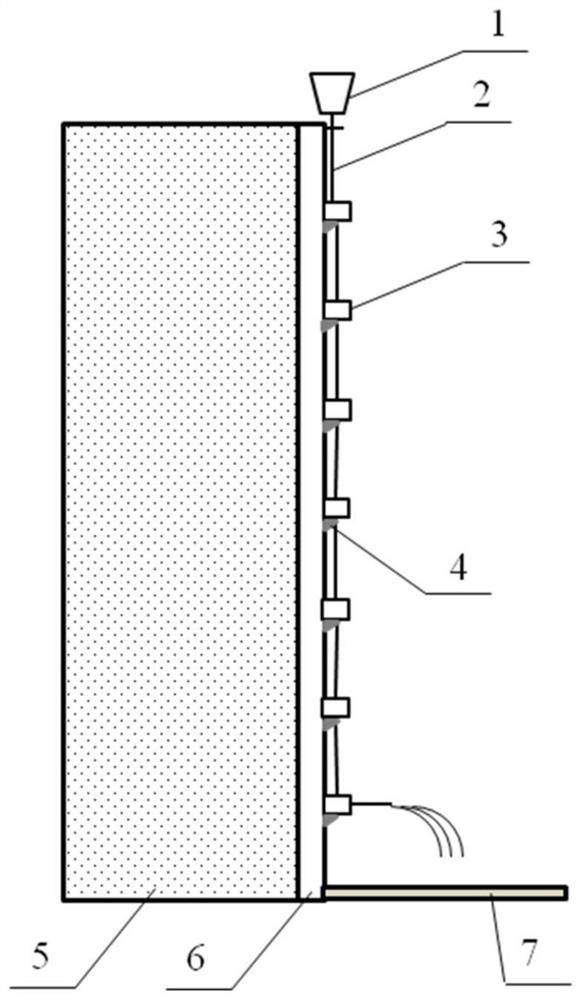

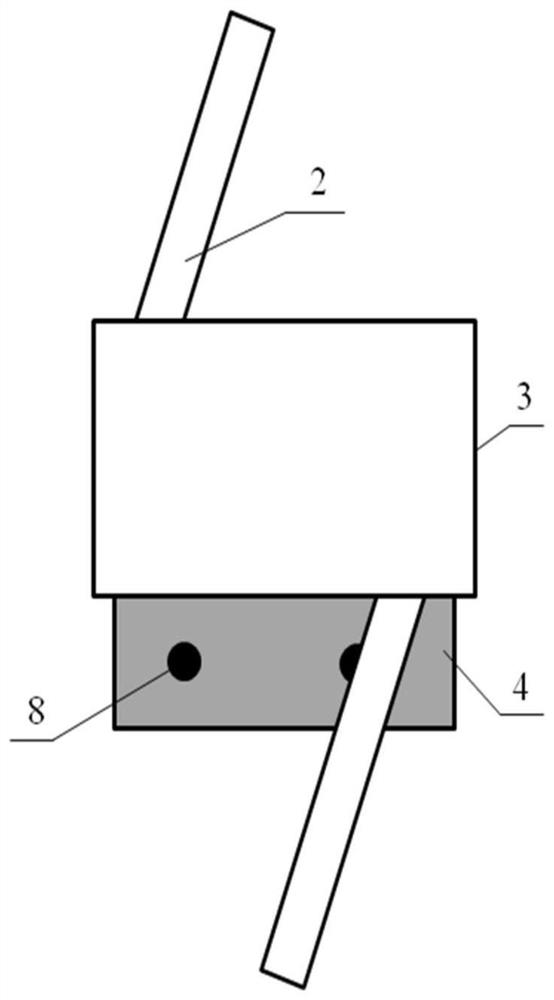

[0027] The design concept of a method for pouring self-flowing energy-dissipating concrete in deep foundation pits proposed by the present invention is: by adopting concrete self-flowing energy-dissipating structures to pour concrete in deep foundation pits, the concrete with higher kinetic energy flowing in from the upper drainage conduit passes through multi-stage energy-dissipating The buffer function of the box reduces the kinetic energy of the concrete, which is transported to the lower part through the drainage conduit at the lower part, and the energy is dissipated step by step. The energy dissipation box is connected with the lining wall through a triangular fixed structure, so as to ensure that the energy dissipation box can still be fixed in position when it bears a relatively large impact force. A drainage funnel is arranged at the entrance of the surface drainage conduit to facilitate the flow of concrete into the drainage conduit and transport to the deep undergrou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com