Fabricated wallboard structure capable of being repeatedly disassembled and assembled and installing method of fabricated wallboard structure

An installation method and prefabricated technology, which can be used in building components, building structures, and building materials processing, etc., can solve the problem that two wall panels cannot be connected, increase the distance between the wall panel and the wall, and have large gaps between the wall panels. problem, to achieve the effect of good decoration effect, good aesthetics and controllable gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

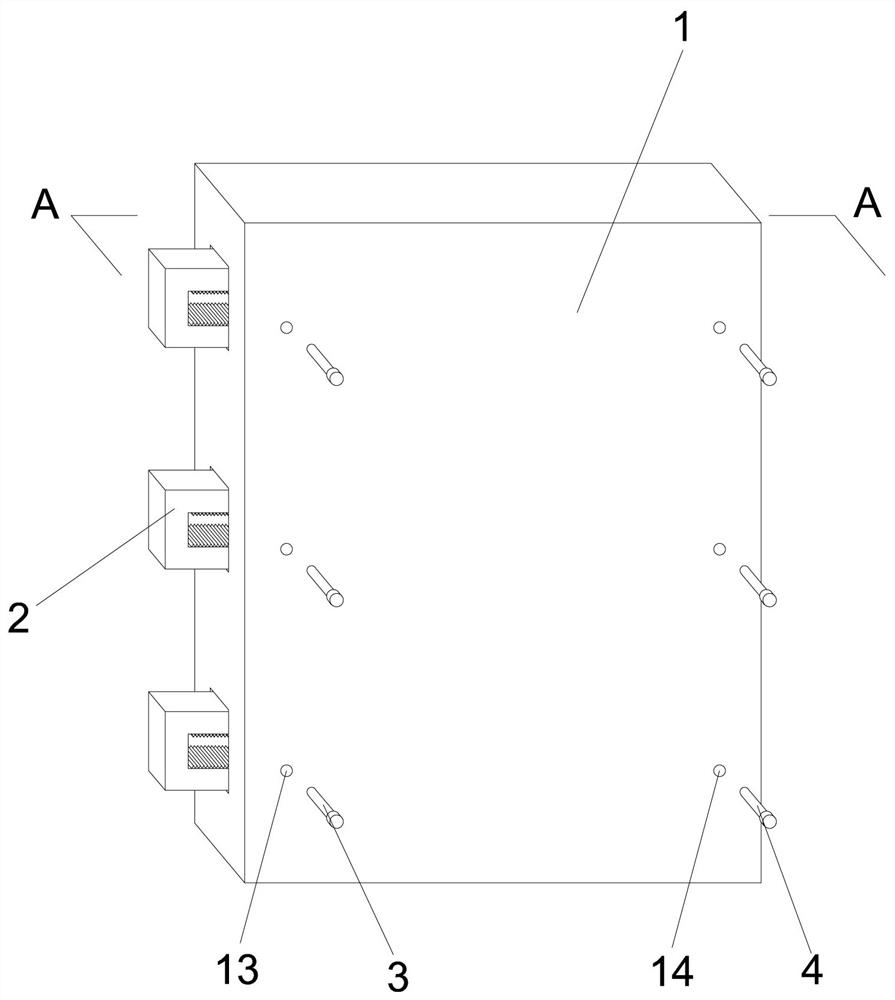

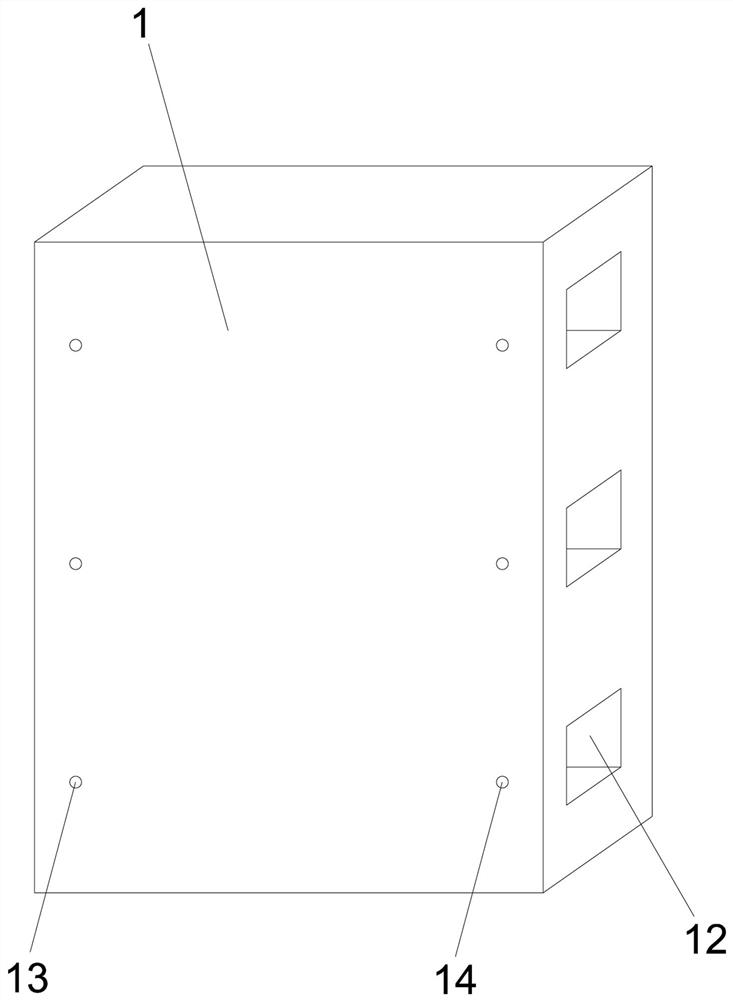

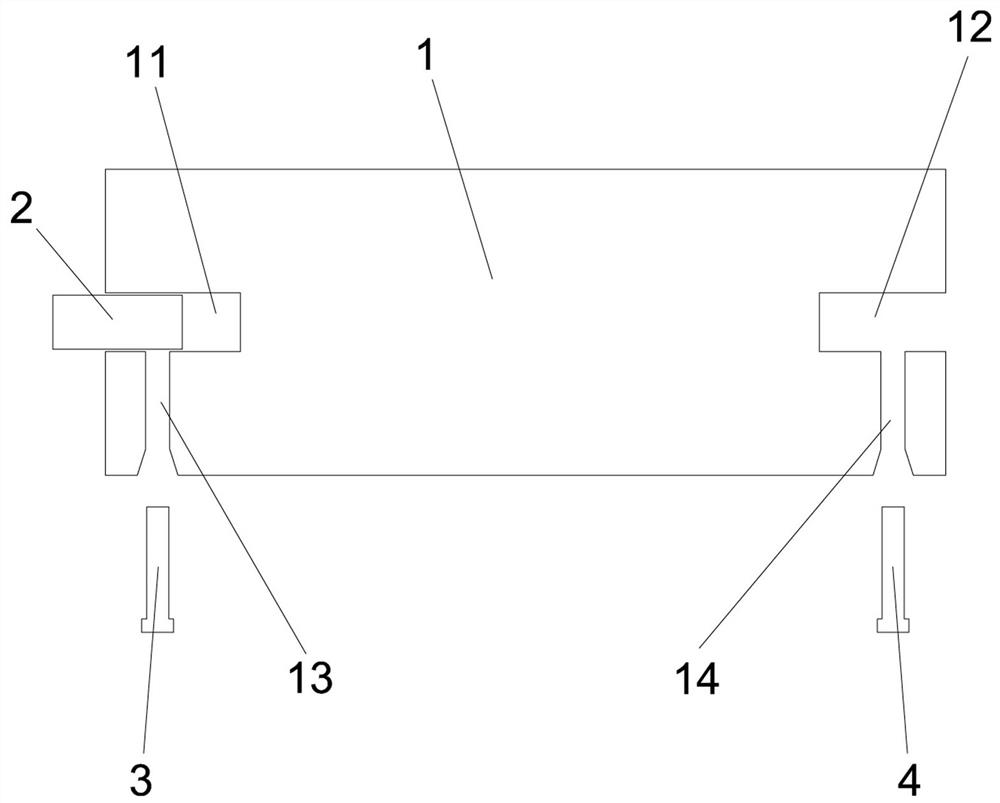

[0040] Embodiment one: if Figures 1 to 6 As shown, it is only one of the embodiments of the present invention, a removably assembled wall panel structure, including a panel body 1, the side wall of the panel body 1 is provided with a first card slot 11, the The side of the plate body 1 away from the first card slot 11 is provided with a second card slot 12, the first card slot 11 is provided with a protruding plate 2, and the plate body 1 is provided with a A first through hole 13 communicating with the slot 11 and a second through hole 14 for communicating with the second slot 12, the first through hole 13 is provided with a first stud 3, and the second through hole 14 is A second stud 4 is provided, a horizontal groove 21 is arranged in the middle of the extension plate 2, at least a part of the first stud 3 is located in the horizontal groove 21, and the inner wall of the horizontal groove 21 is provided with a first Detent 22, the outer side of the first stud 3 is provid...

Embodiment 2

[0049] Embodiment two, still as Figures 1 to 6 As shown, it is only one of the embodiments of the present invention. On the basis of Embodiment 1, in the assembled wall panel structure of the present invention that can be reassembled and disassembled, the first latch 22 is set in the horizontal groove At least one of the upper side of the inner side of the horizontal groove 21 and the lower side of the inner side of the horizontal groove 21 . That is to say, the first locking teeth 22 can only be arranged on the upper side of the inner side of the horizontal groove 21, or can only be arranged on the lower side of the inner side of the horizontal groove 21, or can be arranged on the inner side of the horizontal groove 21 at the same time. The upper side of the inner side and the lower side of the inner side of the horizontal groove 21 are all provided with the first locking teeth 22, generally speaking, the first locking teeth 22 are arranged on the upper and lower sides of th...

Embodiment 3

[0055] Embodiment three, such as Figure 7 As shown, the present invention also provides a method for installing a removably disassembled assembled wall panel structure in all the above-mentioned embodiments, including the following steps:

[0056] S1: Set an extension plate in the first slot on one side of the board to be installed, lift the board to be installed to the side of the other board that has been installed and align it;

[0057] S2: Insert a first stud into the first through hole on the board to be installed that communicates with the first slot, so that the first stud passes through the first through hole and inserts into the horizontal groove extending out from the middle of the board;

[0058] S3: Turn the first stud, and under the cooperation of the second latch on the outside of the first stud and the first latch on the inside of the horizontal groove, the protruding plate is protruded from the first slot and inserted into the installed plate in the second ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com