A kind of threading hole sealing device and sealing method for negative pressure device

A technology of negative pressure device and sealing device, applied in the field of wind tunnel test, can solve the problems of poor sealing and poor stability, and achieve the effects of increased sealing performance, good sealing effect and great applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

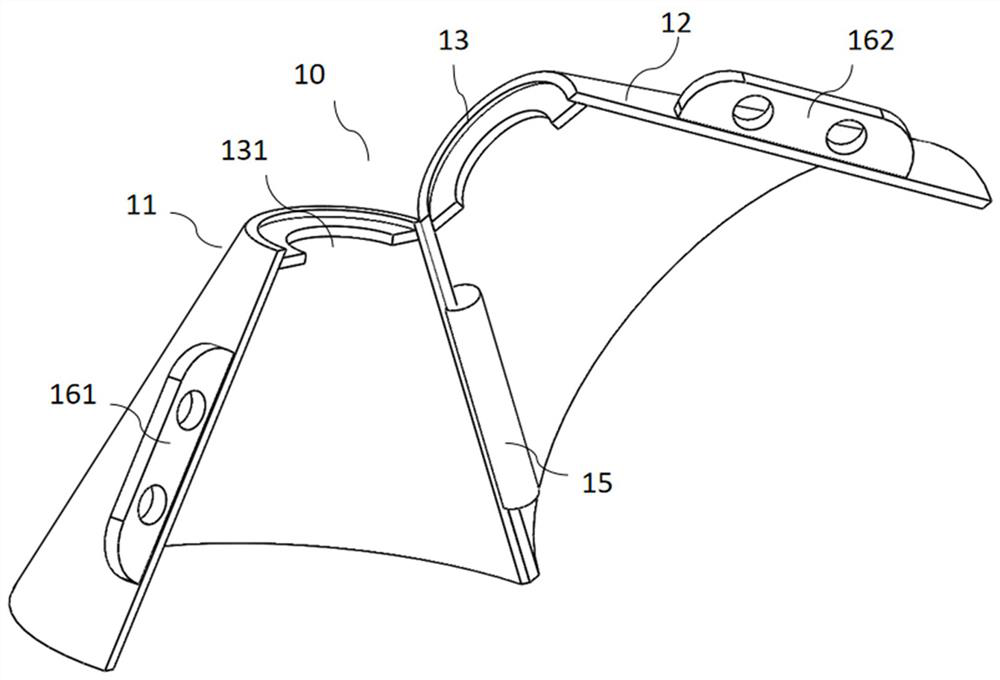

[0038] Embodiment 1 provides a sealing device for threading holes in a vacuum wind tunnel, such as figure 1 As shown, it includes a mounting sleeve 10 and a connecting piece (not shown in the figure); the mounting sleeve 10 is a hollow circular truncated structure, including a first mounting sleeve main body 11 and a second mounting sleeve main body 12 arranged symmetrically. An installation sleeve main body 11 and a second installation sleeve main body 12 are hinged; the inside of the installation sleeve 10 is provided with a first partition 13; the first partition 13 is respectively arranged on the first installation sleeve main body 11 and the second installation sleeve The first left partition and the first right partition on the inner surface of the two installation sleeve main bodies 12 are composed; 10 coaxial; the first mounting sleeve main body 11 is provided with a first connecting portion 161; the second mounting sleeve main body 12 is provided with a second connect...

Embodiment 2

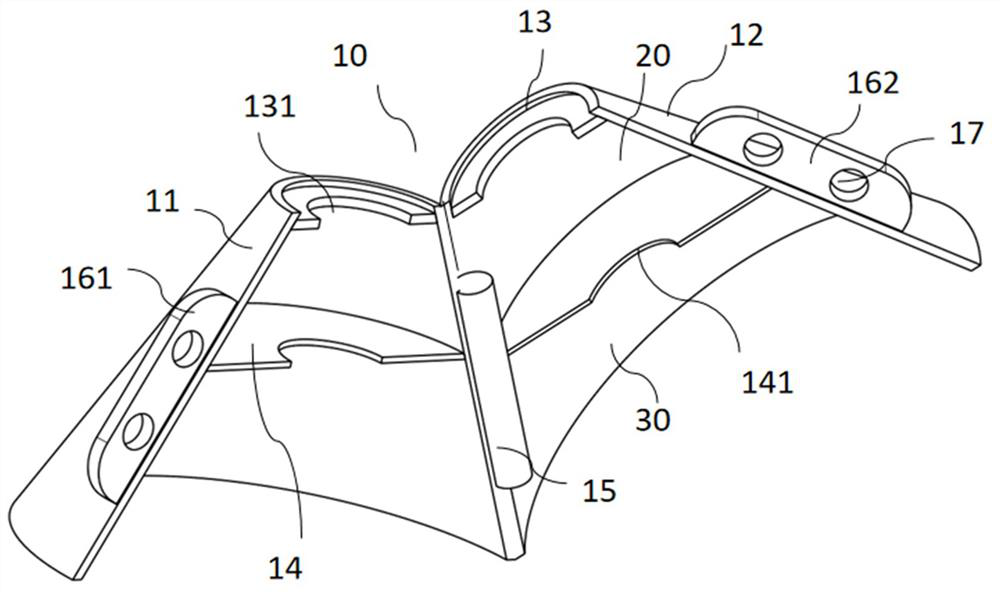

[0052] This embodiment also provides a sealing device for threading holes used in a vacuum wind tunnel. The difference from Embodiment 1 is that a second partition 14 is also provided in the installation sleeve of the sealing device 1 in this embodiment, such as figure 2 shown.

[0053] In this embodiment, a second partition 14 is also provided on the inner surface of the installation sleeve 10, and the second partition 14 divides the entire interior space of the installation sleeve 10 into a first accommodating space 20 and a second accommodating space 30 The first accommodating space 20 is the space between the first partition 13 and the second partition 14; the other part is the second accommodating space; the second partition 14 is provided with the first Two threading holes 141 , the second threading hole 141 is coaxial with the first threading hole 131 and the installation sleeve 10 .

[0054] In this embodiment, the installation position of the second partition 14 is ...

Embodiment 3

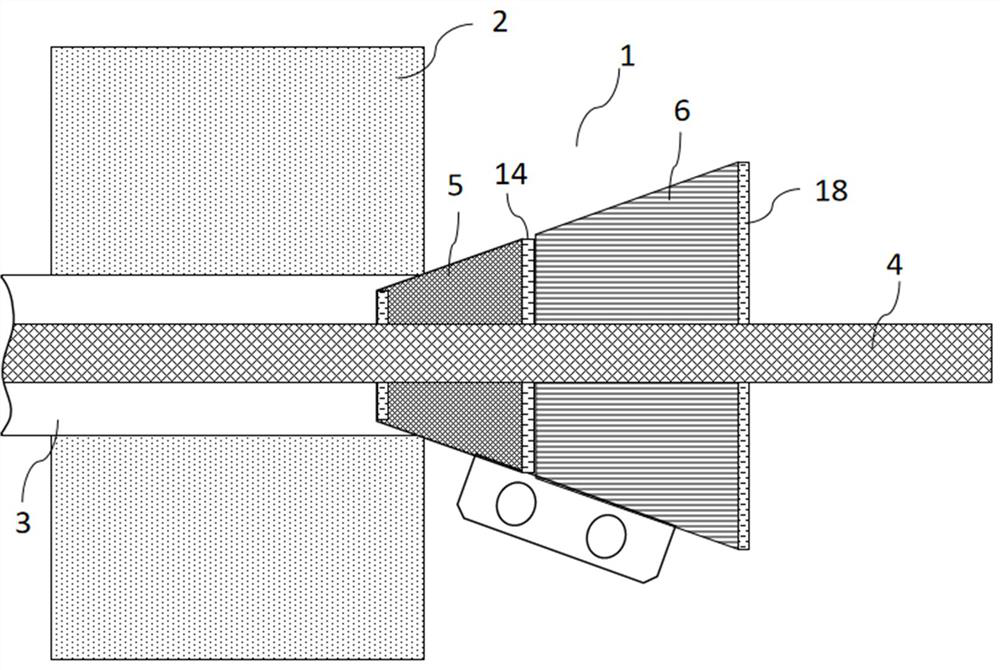

[0057] This embodiment provides a method for sealing the threading hole of a vacuum wind tunnel, using the sealing device as in Embodiment 1 for sealing, and the flow of the specific sealing method is as follows Figure 4 shown.

[0058] S10. Fill the sealing plugging mud into the internal accommodation space of the first installation sleeve main body 11 and the second installation sleeve main body 12;

[0059] In this embodiment, the sealing mud is filled into the accommodating space surrounded by the side wall between the first left partition and the bottom end of the first installation sleeve main body 11, and the first right partition and the second installation sleeve main body. In the accommodating space enclosed by the side walls between the bottom ends of 12;

[0060] Rotate and separate the first installation sleeve main body 11 and the second installation sleeve main body 12 of the sealing device 10, exposing the internal accommodation space of the first installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com