Continuous decontamination device

A technology for decontamination agents and articles, which can be applied to spray devices, water supply devices, liquid spray devices, etc., and can solve problems such as a lot of time and multiple times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

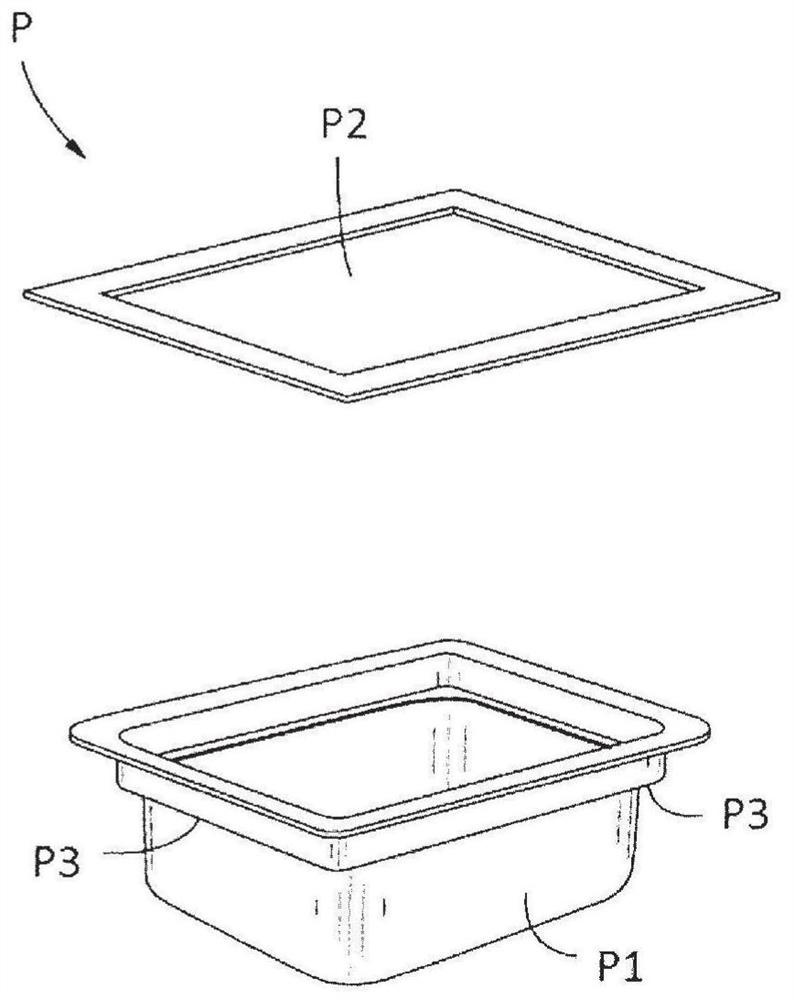

[0055] figure 1 It is a perspective view which shows the storage body (package body) which uses the continuous decontamination apparatus concerning this 1st Embodiment as a decontamination object. However, in the present invention, the shape of the container is not limited to figure 1 shape. exist figure 1 Among them, the package P includes a polyethylene protrusion P1 and a Tyvek (trademark) top surface sealant P2. In the first embodiment, the sterilized syringes used in the filling operation of the plurality of prefilled syringes are housed therein and decontaminated in a sealed state.

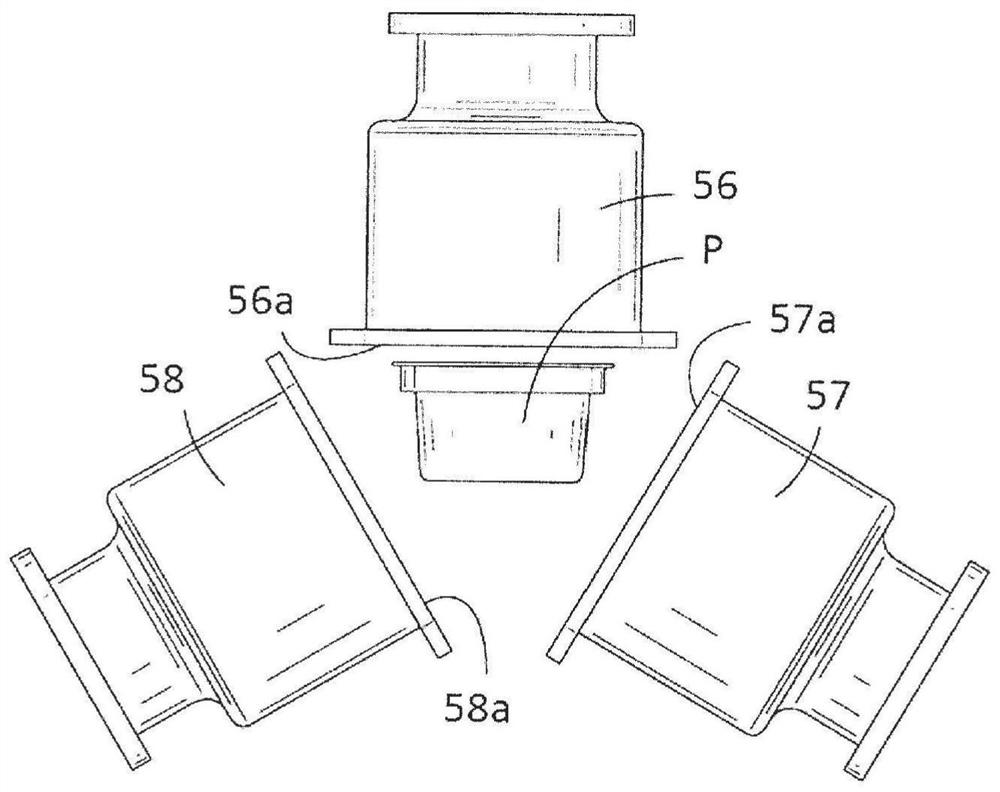

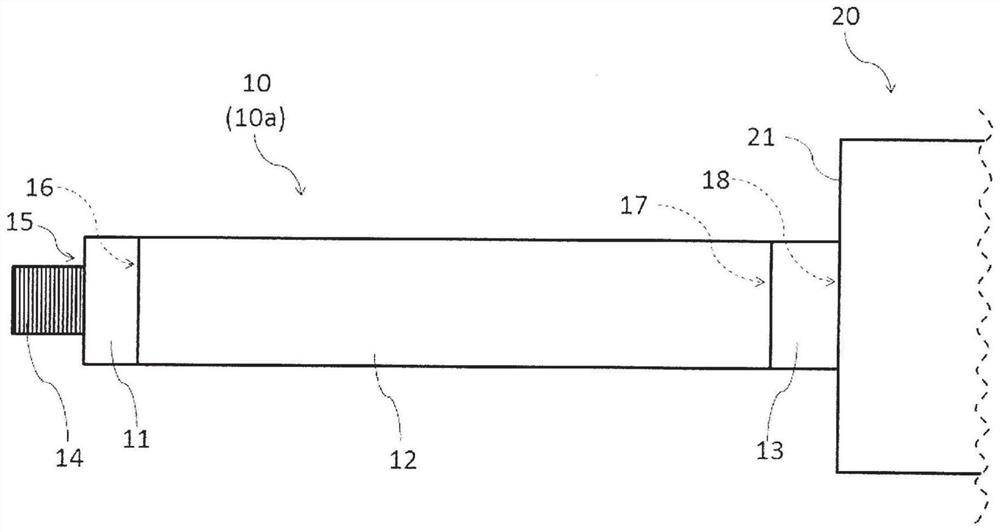

[0056] Next, the continuous decontamination device according to the first embodiment will be described. image 3 It is a schematic plan view showing the continuous decontamination device according to the first embodiment, Figure 4 It is a schematic front view showing the continuous decontamination device. The continuous decontamination device according to the first embodiment includes...

no. 2 approach >

[0093] In this second embodiment, the number and arrangement of vibrating disks of the mist control device are changed with respect to the above-mentioned first embodiment. Figure 11 It is a schematic diagram showing the relationship between the mist supply device and the mist control device according to the second embodiment. Figure 11 (A) is a front cross-sectional view of the package P placed on the roller conveyor 114 as viewed toward the traveling direction. Figure 11 (B) is a side cross-sectional view of the package P placed on the roller conveyor 114 as viewed from the transverse direction of the traveling direction (arrow direction in the figure).

[0094] exist Figure 11 In the inside of the decontamination area 112 of the apparatus main body 110a, the package P is placed and conveyed on the roller conveyor 114. In this second embodiment, the same two-fluid nozzle 130 as in the above-mentioned first embodiment is used as the mist supply device 130 , and is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com