Washing solution generating device, washing/coating solution generating device

A technology for generating devices and cleaning fluids, applied in cleaning methods and appliances, cleaning methods using liquids, water/sewage treatment, etc., can solve problems such as dirt falling off the outer plate, and achieve the effect of a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

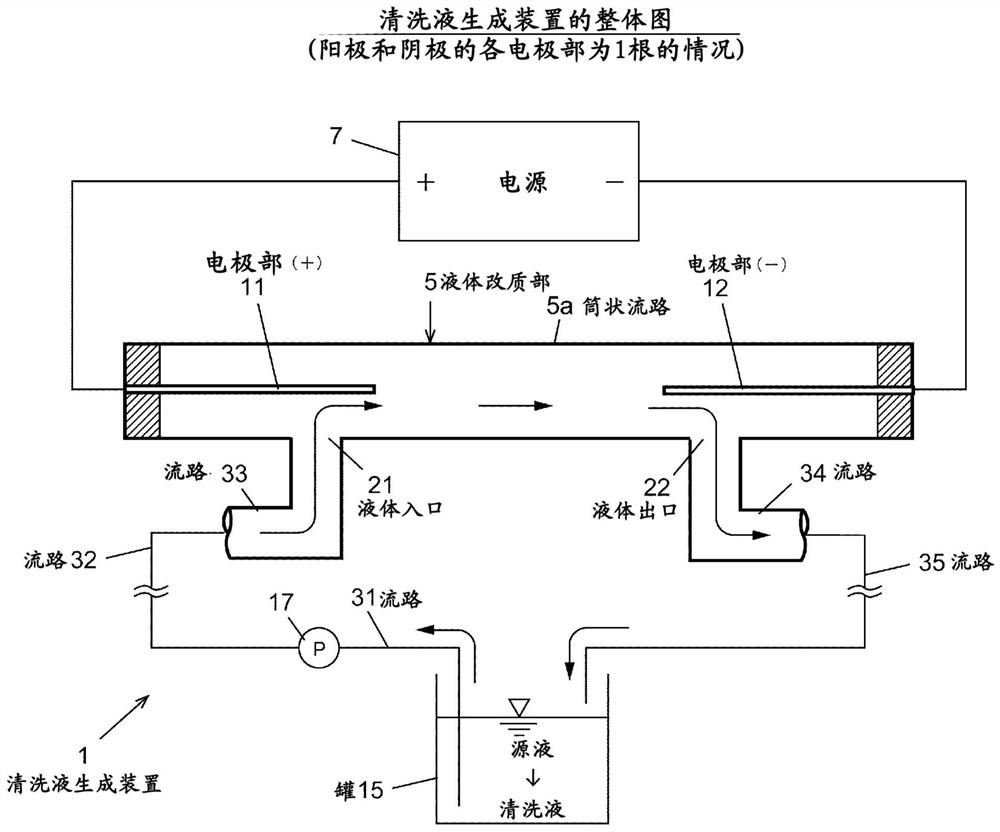

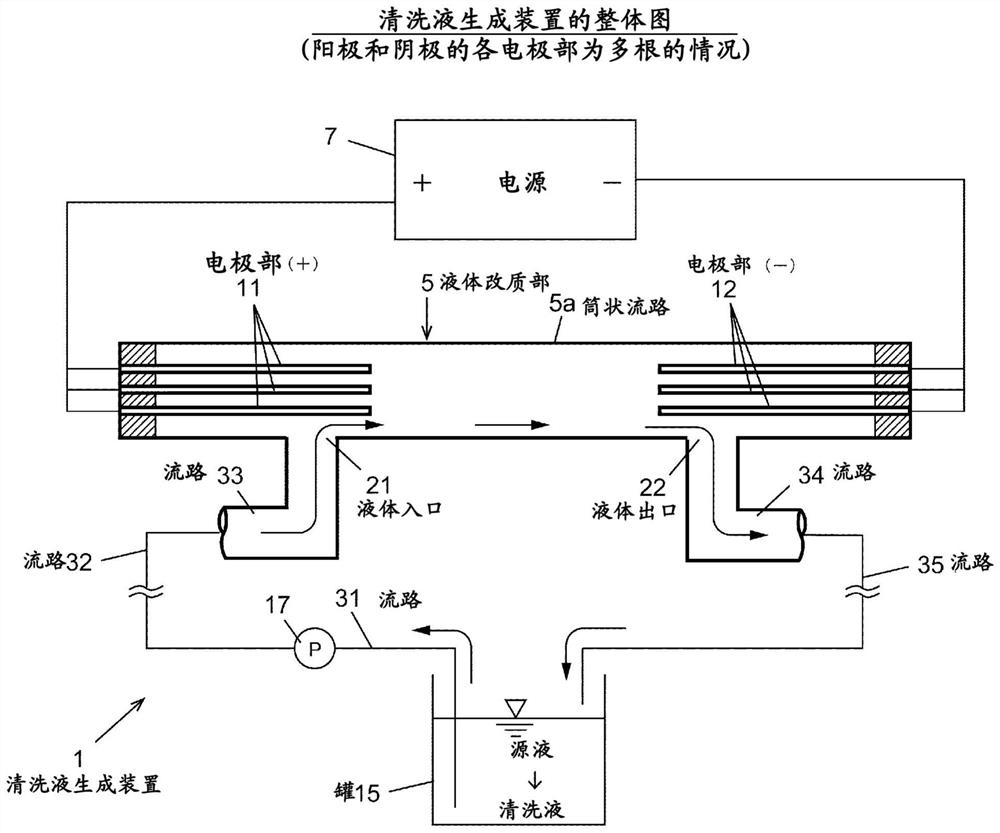

[0084] Hereinafter, examples of the present invention will be described using experimental examples. The cleaning liquid generation device used in the experiment has the same figure 1 The same result was obtained for the device of the first embodiment shown. The specific specifications of the apparatus and power supply used in the experiment are as follows.

[0085] (Specifications of cleaning solution generator)

[0086] Dimensions of the cylindrical flow path: 18mm outer diameter, 13mm inner diameter, 300mm overall length

[0087] ■Cylinder flow path material: Rigid vinyl chloride tube

[0088] ■Anode electrode rod: a copper rod with a diameter of 2mm and a length of 100mm

[0089] ■Cathode electrode rod: a copper rod with a diameter of 2mm and a length of 100mm

[0090] ■Interval between anode and cathode: 100mm

[0091] (Specification of power supply)

[0092] ■AC100V: (AC100~120V, maximum 2A) input power

[0093] ■Voltage between cathode and anode: 5~30V (Variable...

Embodiment 2

[0108] Using a cleaning-coating liquid production device, a cleaning-coating liquid was produced, and an experiment was conducted to confirm the double function of the cleaning effect and the coating effect of the cleaning-coating liquid. The cleaning-coating liquid generation device used in the experiment has the same Figure 4 The device of the first embodiment shown has the same configuration. The specific specifications of the device used in the experiment and the power supply are the same as in Example 1. Prepare the washing-coating solution generator and power supply of the above specifications. Then, "public tap water" was prepared as a liquid to be the source liquid of the washing-coating liquid to be produced, and the washing-coating liquid was produced using the washing-coating liquid production device. This generation is to turn on the switch of the power supply 7 under the state that there is liquid flowing inside the cylindrical flow path 5a, and the liquid that...

Embodiment 3

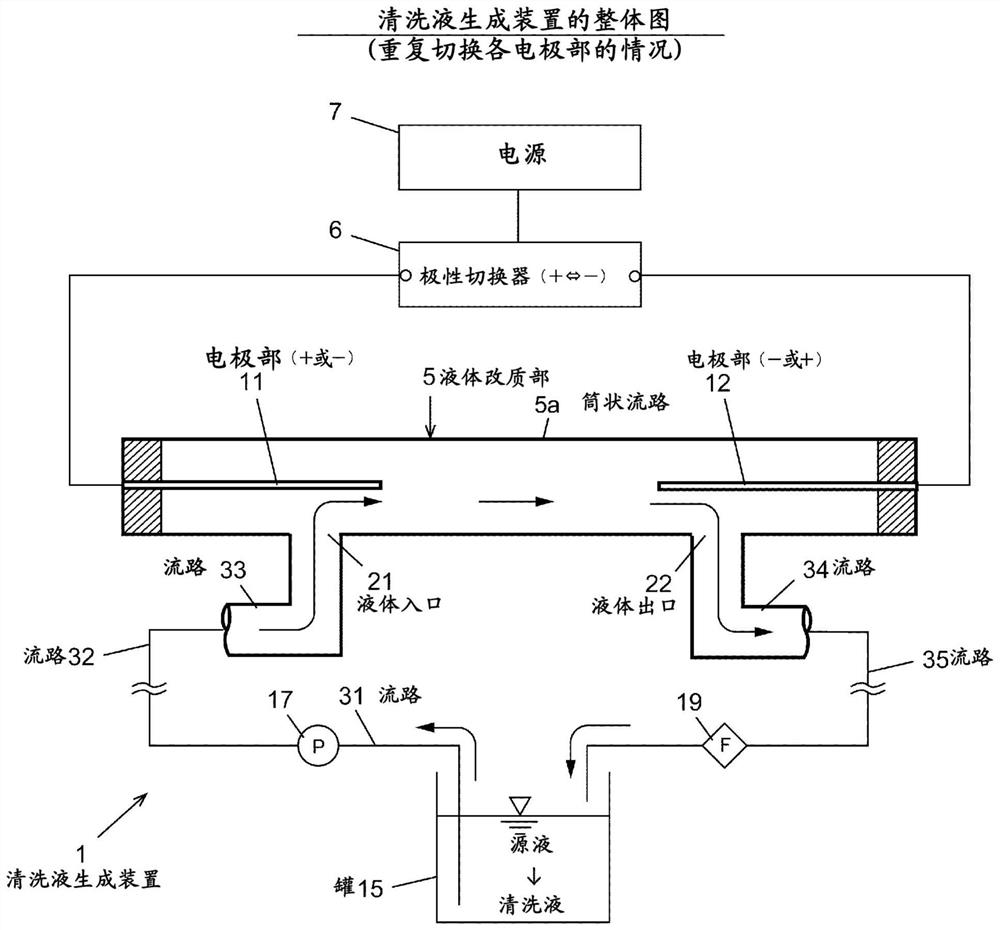

[0130] An experiment was conducted to confirm the effect of inhibiting the fouling of the liquid reforming part by generating a cleaning liquid using a cleaning liquid generating device provided with a polarity switching part. The cleaning liquid generation device used in the experiment has the same image 3The device of the third embodiment shown has the same configuration. The specific specifications of the cleaning liquid generating device (cylindrical flow path) and power supply used in the experiment are the same as those in Example 1 above. "Tap water" was prepared as the liquid to be the source liquid of the cleaning liquid to be generated, and the cleaning liquid was generated using the cleaning liquid generating device (the device according to the third embodiment) of the above specification. At this time, with the liquid flowing inside the cylindrical flow path 5a, the switch of the power supply 7 is turned on, and a voltage is applied to the liquid in contact with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com