Vapor drying method, apparatus therefor and storage medium

A technology of drying method and drying device, which is applied in the direction of separation method, chemical instrument and method, sustainable manufacturing/processing, etc., can solve problems such as inert gas waste, flow limitation, and longer second drying treatment time, and achieve effective Utilize and achieve the effect of drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

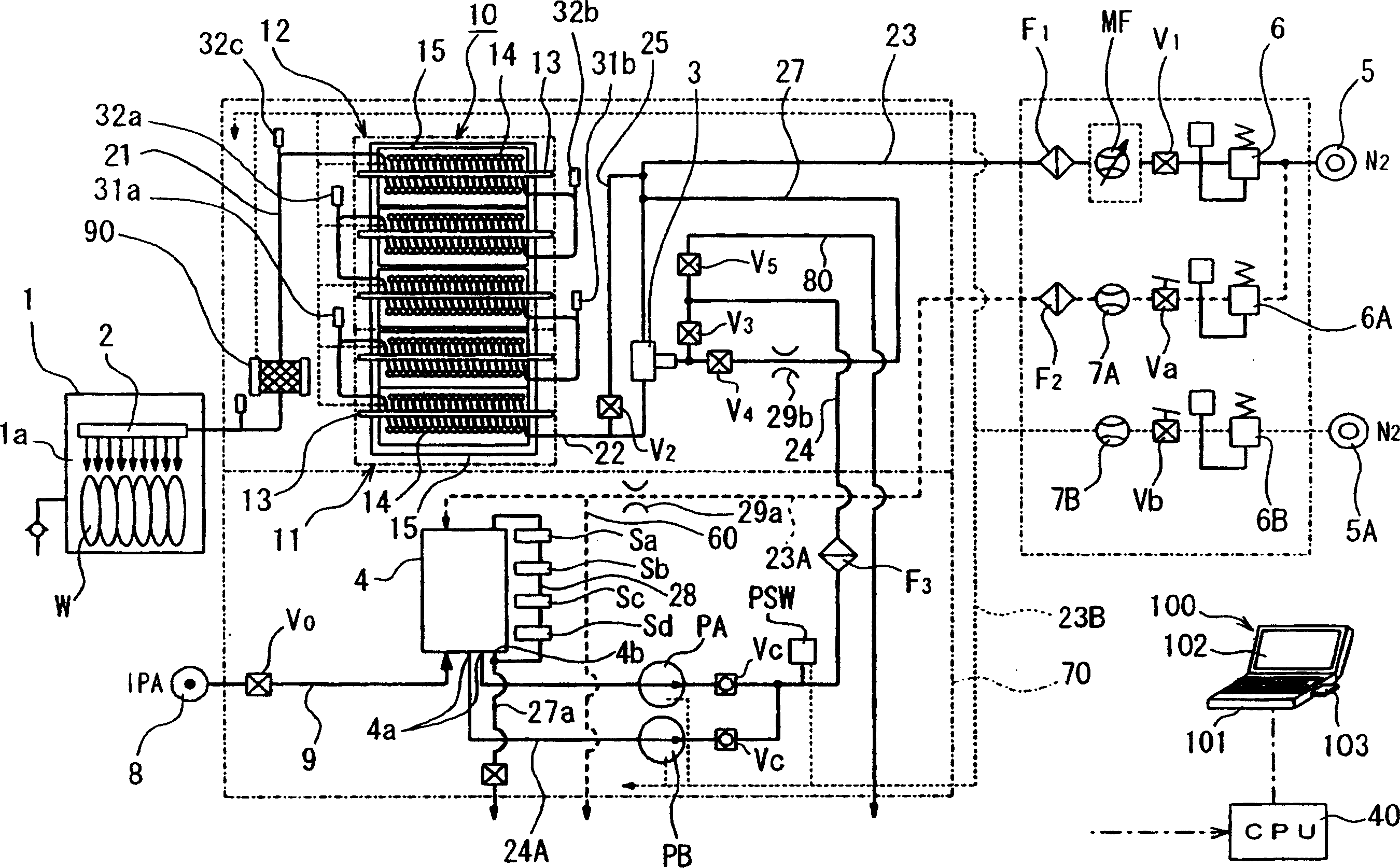

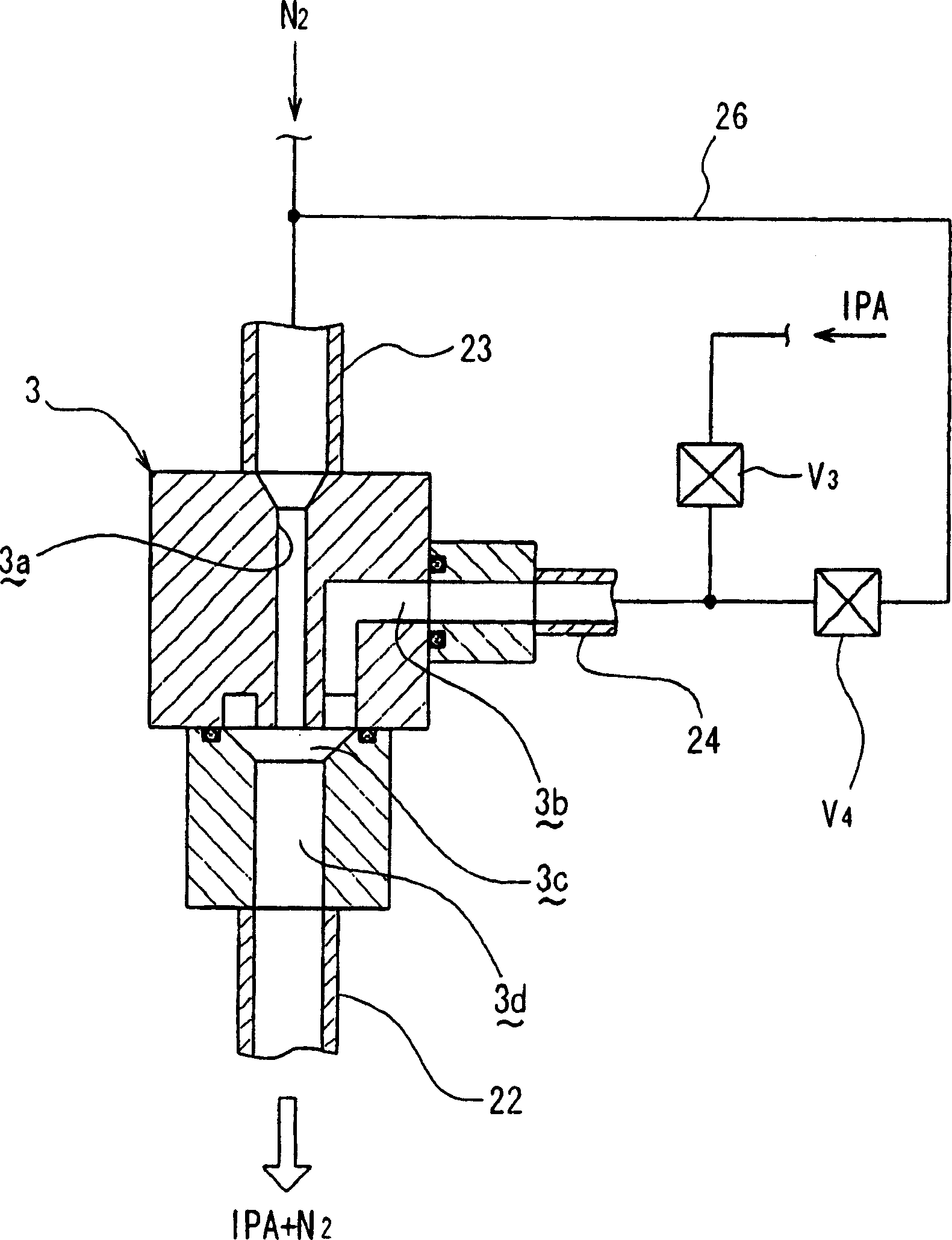

[0052] Hereinafter, specific embodiments of the present invention will be described in detail based on the drawings. Here, a case where the steam drying apparatus of the present invention is applied to a semiconductor wafer rinsing and drying processing system will be described.

[0053] figure 1 It is a schematic configuration diagram showing the whole of the above-mentioned washing and drying treatment system, figure 2 It is a schematic sectional view showing the mixed fluid generating mechanism of the present invention.

[0054] The rinsing and drying processing system described above is provided with: a processing container 1 having a processing chamber 1a for accommodating a semiconductor wafer W (hereinafter referred to as a wafer W) as an object to be processed; (spray) drying steam or an inert gas such as nitrogen (N 2 ) gas supply mechanism; steam generator 10 is to generate IPA (isopropanol) and N as steam solvent 2 The steam generating mechanism of the steam of...

no. 2 Embodiment approach

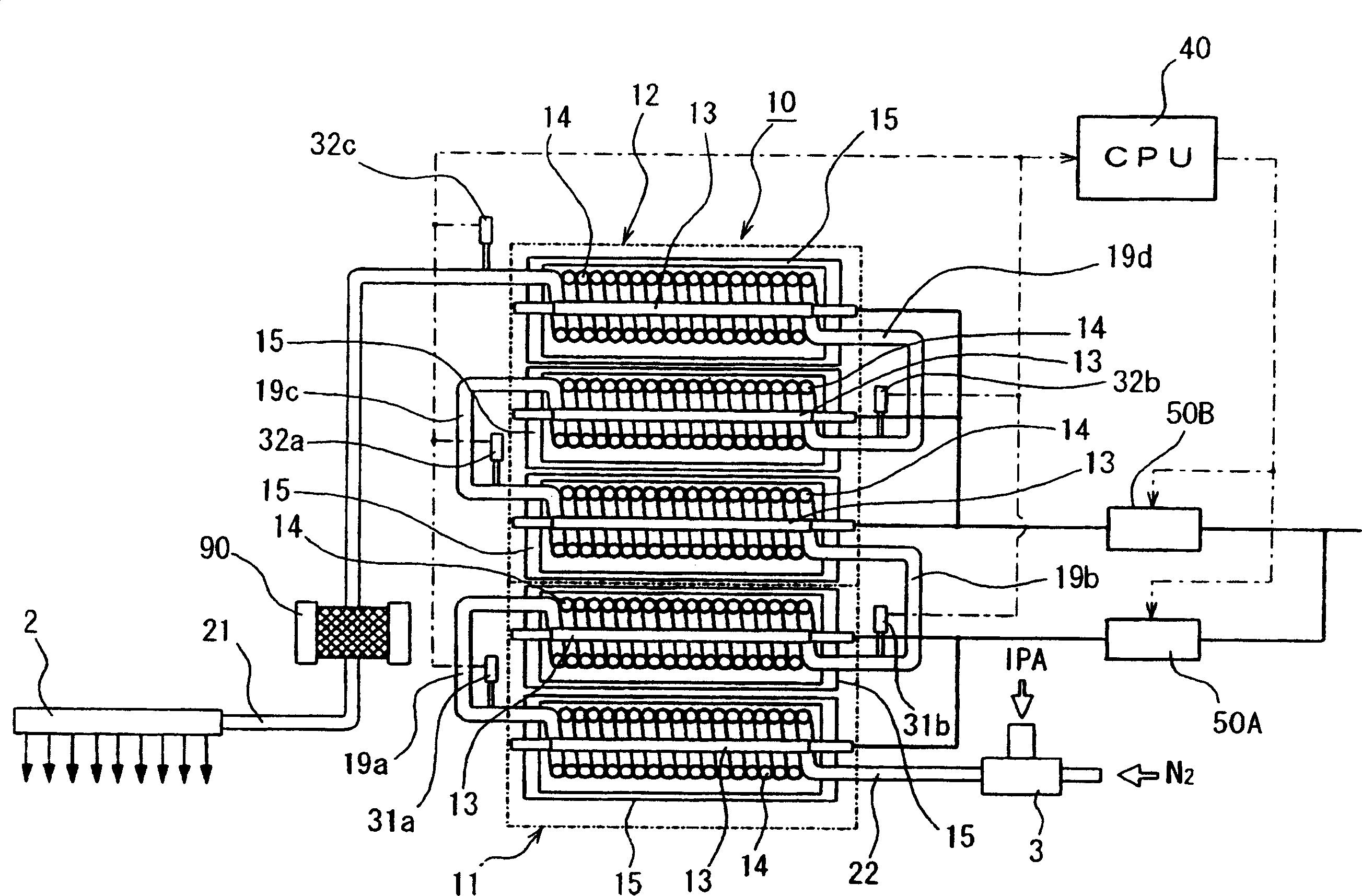

[0093] Hereinafter, preferred embodiments of the present invention will be described in detail based on the drawings. Here, a case where the steam drying apparatus of the present invention is applied to a semiconductor wafer rinsing and drying processing system will be described.

[0094] Fig. 6 is a schematic configuration diagram showing the overall structure of the above-mentioned washing and drying treatment system, Figure 7 It is a schematic sectional view showing the main part of the above-mentioned processing apparatus of the present invention.

[0095] The rinsing and drying processing system described above is provided with: a processing container 1 having a processing chamber 1a for accommodating a semiconductor wafer W (hereinafter referred to as a wafer W) as an object to be processed; (Jet) supply mechanism of steam for drying; steam generator 10 of the present invention generates IPA (isopropanol) and N 2 The steam of the mixed fluid of the gas; the two-fluid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com