Lifting rotary type guniting device

A lifting, rotating and spraying technology, applied in shaft equipment, shaft lining, tunnel lining, etc., can solve the problems of high work intensity and harsh working environment for workers, and achieve fast and efficient construction, time-saving shotcrete, and convenient construction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

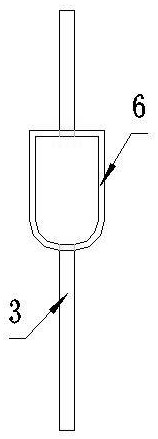

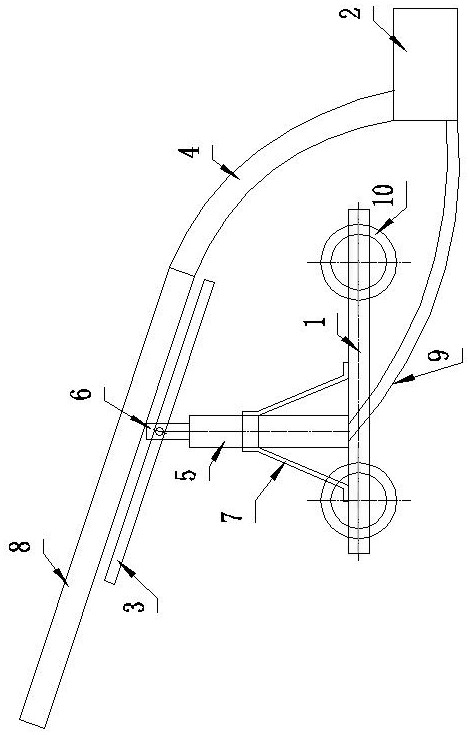

[0016] A lifting and rotating spraying device, including a lifting cylinder 5, which is fixed on the vehicle chassis, a support frame 3 is fixed on the piston rod of the lifting cylinder 5, and a wear-resistant spraying head 8 is fixed on the support frame 3 , the wear-resistant spraying head 8 is connected with the wear-resistant spraying pipe 4, the wear-resistant spraying pipe 4 is connected with the spraying port of the pneumatic spraying machine 2, the air outlet of the pneumatic spraying machine 2 is connected with the inlet of the lifting cylinder 5 Air outlet connection.

[0017] Described chassis is made of base 1 and road wheel 10, and road wheel 10 is 4, and 4 road wheels 10 divide two pairs and are installed on the front portion and the rear portion of base 1 respectively.

[0018] The walking wheels 10 are pneumatic walking wheels with tires.

[0019] A support 7 is provided between the lifting cylinder 5 and the base 1 .

[0020] The bracket 7 is composed of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com