Novel cold-proof power cable

A power cable, a new type of technology, applied in the field of new cold-proof power cables, can solve the problems of poor cold-proof effect and achieve the effect of solving the problem of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

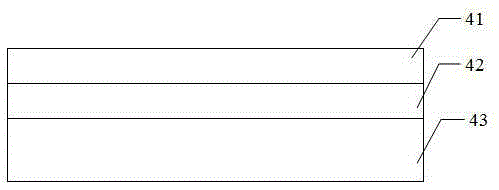

[0022] The outer sheath includes a glass fiber base layer 61, a chlorinated polyvinyl chloride layer 62 and a protective layer 63 from the inside to the outside, wherein the chlorinated polyvinyl chloride layer 62 is pressed on the glass fiber base layer 61, and then the chlorinated polyvinyl chloride layer The outer side of vinyl layer 62 is coated with protective layer 63 to obtain the outer sheath material of the present invention.

[0023] The protective layer 63 includes the following raw materials by weight: 38 parts of polyurethane resin, 26 parts of fluorosilicone resin, 17 parts of silicone crosslinking agent, 18 parts of silicon dioxide, 14 parts of silicon hydroxide, 13 parts of magnesium hydroxide, 6 parts Iron oxide, 5 parts of barium sulfate, 4 parts of lubricant, 5 parts of antioxidant, 2.5 parts of compatibilizer, 1.5 parts of silicone leveling agent, 0.3 parts of nano silver and 0.8 parts of nano zinc oxide. The compatibilizer is ST-6 compatibilizer. The lubr...

Embodiment 2

[0036] The outer sheath includes a glass fiber base layer 61, a chlorinated polyvinyl chloride layer 62 and a protective layer 63 from the inside to the outside, wherein the chlorinated polyvinyl chloride layer 62 is pressed on the glass fiber base layer 61, and then the chlorinated polyvinyl chloride layer The outer side of vinyl layer 62 is coated with protective layer 63 to obtain the outer sheath material of the present invention.

[0037] The protective layer 63 includes the following raw materials by weight: 37 parts of polyurethane resin, 25 parts of fluorosilicone resin, 17 parts of silicone crosslinking agent, 17 parts of silicon dioxide, 13 parts of silicon hydroxide, 12 parts of magnesium hydroxide, 6 parts Iron oxide, 5 parts of barium sulfate, 4.5 parts of antioxidant, 2.5 parts of compatibilizer, 1.5 parts of silicone leveling agent, 0.2 part of nano silver and 0.6 part of nano zinc oxide. The compatibilizer is ST-6 compatibilizer. The lubricant is paraffin.

...

Embodiment 3

[0049]The outer sheath includes a glass fiber base layer 61, a chlorinated polyvinyl chloride layer 62 and a protective layer 63 from the inside to the outside, wherein the chlorinated polyvinyl chloride layer 62 is pressed on the glass fiber base layer 61, and then the chlorinated polyvinyl chloride layer The outer side of vinyl layer 62 is coated with protective layer 63 to obtain the outer sheath material of the present invention.

[0050] The protective layer 63 includes the following raw materials by weight: 39 parts of polyurethane resin, 27 parts of fluorosilicone resin, 18 parts of silicone crosslinking agent, 18 parts of silicon dioxide, 14 parts of silicon hydroxide, 13 parts of magnesium hydroxide, 7 parts Iron oxide, 6 parts of barium sulfate, 5 parts of antioxidant, 3 parts of compatibilizer, 2 parts of silicone leveling agent, 0.4 part of nano silver and 0.9 part of nano zinc oxide. The compatibilizer is ST-6 compatibilizer. The lubricant is paraffin.

[0051] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com