Processing device and method for mobile phone heat pipe without sintered copper mesh

A processing device, non-sintering technology, applied in chemical instruments and methods, solid separation, classification, etc., can solve the problems of low measurement efficiency, increased labor, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

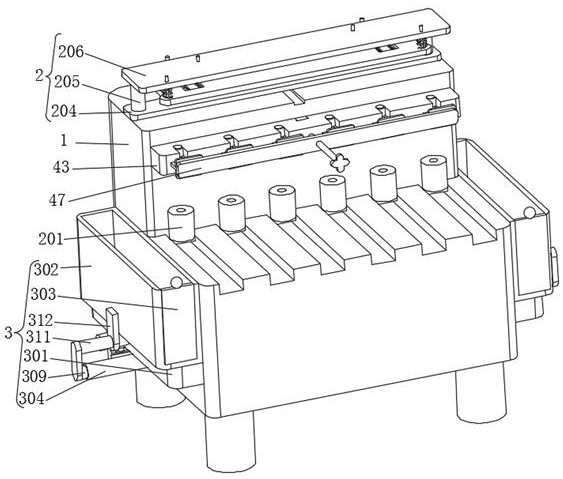

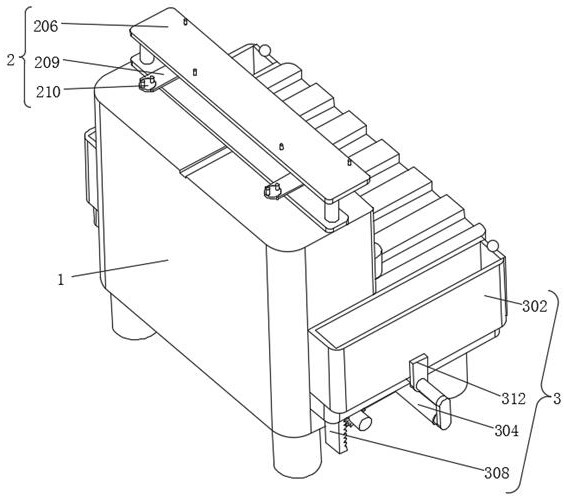

[0037] Example 1, such as Figure 1-8 As shown, the present invention provides a processing device and method for a mobile phone heat pipe without sintered copper mesh, including a workbench 1 and a screening structure 2, and the surface of the workbench 1 is provided with the sieving structure 2.

[0038] Include the following steps:

[0039] S1. First, the staff transports the oxygen-free copper tube, which is the raw material of the heat pipe, to the vicinity of the workbench 1, and then inserts the oxygen-free copper tube into the cylinder 201;

[0040] S2. At this time, a staff member operates the workbench 1. When screening, first rotate the disc 210, and the disc 210 will adjust the positions of the two cylinders 211, thereby adjusting the height of the long plate 208;

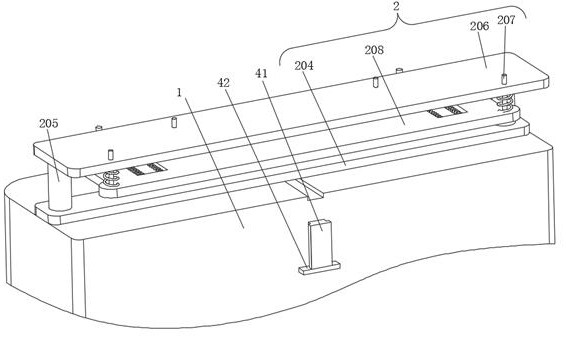

[0041] S3, then the staff slides the slide plate 204, the slide plate 204 will drive the long plate 208 to slide, and the long plate 208 will squeeze the oxygen-free copper tube inserted in the cylinde...

Embodiment 2

[0051] Embodiment 2, on the basis of embodiment 1, as figure 1 and Figure 6 As shown, the surface of the workbench 1 is provided with an auxiliary structure 4, the auxiliary structure 4 includes a limit block 41, the surface of the limit block 41 is fixedly connected with the workbench 1, and the bottom end of the limit block 41 is fixedly connected with a rectangular rod 42, The surface of the limiting block 41 is slidingly connected with a connecting rod 43, the surface of the connecting rod 43 is provided with a connecting groove, the inner wall of the connecting groove is fixedly connected with an arc-shaped block 44, and the end of the connecting rod 43 away from the workbench 1 is threadedly inserted with a screw rod 46 , the surface of the screw 46 is rotated with a fixed plate 47, and the end of the fixed plate 47 close to the connecting rod 43 is fixedly connected with an insert block 45. When a staff member is operating the workbench 1, another staff member inserts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com