High-precision automatic detection device for sensor

An automatic detection device and sensor technology, applied in the field of robotics, can solve the problems of limited accuracy of measuring point positions, manual arrangement of measuring point positions, low measurement efficiency, etc., and achieve the effect of rapid installation and arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific embodiment:

[0020] A high-precision automatic detection device for sensors, including a high-precision intelligent operation unit and a portable base;

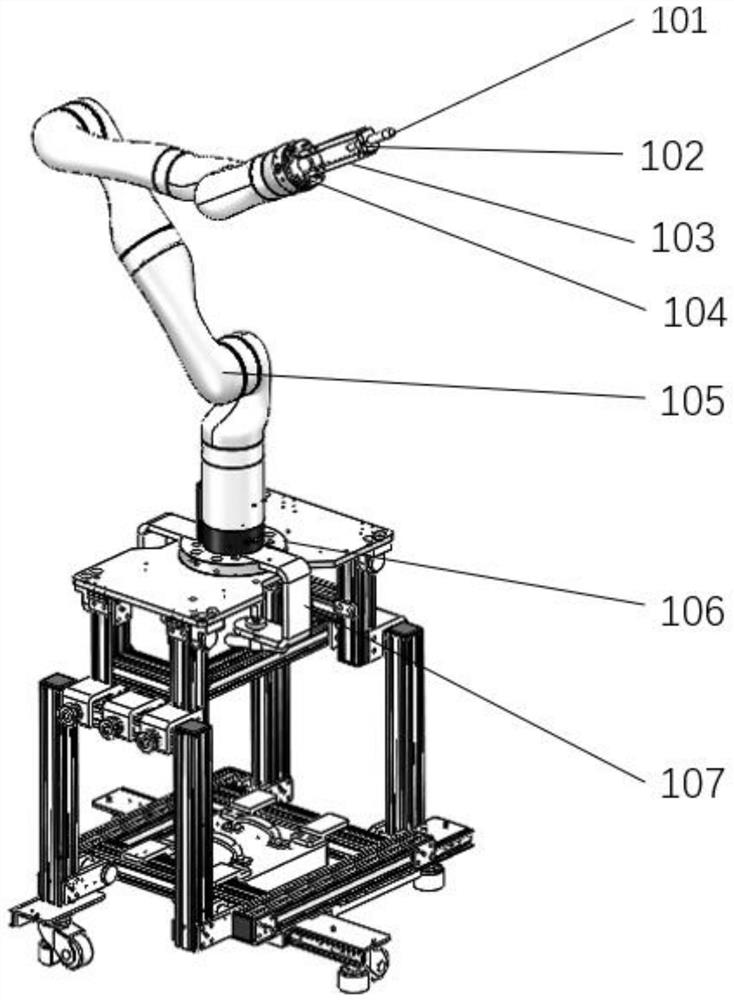

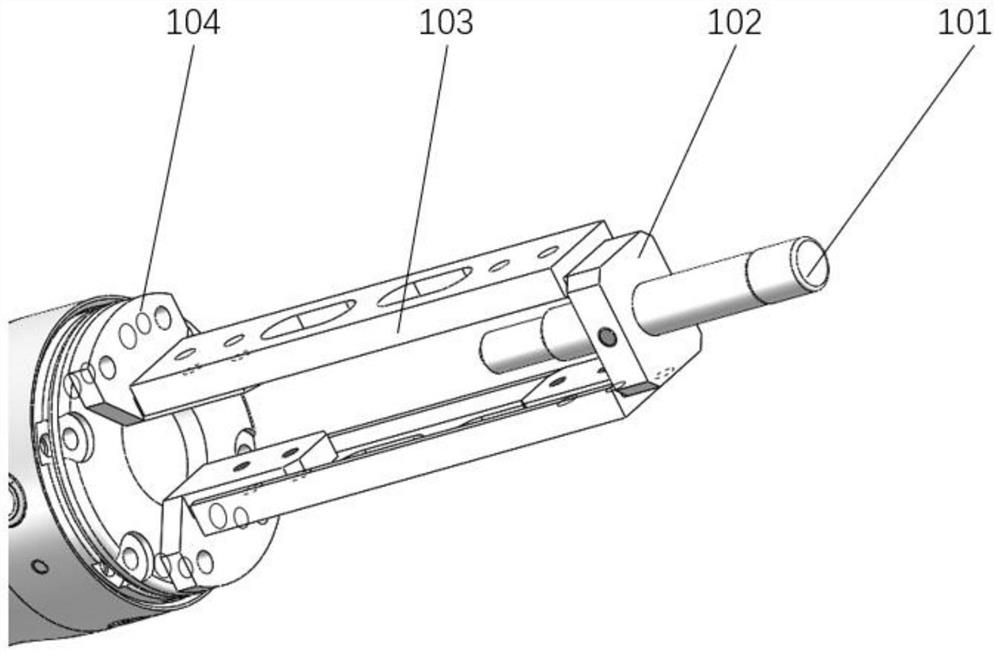

[0021] Such as figure 1 As shown, the high-precision intelligent operation unit includes a tooling fixture, a seven-degree-of-freedom mechanical arm 105, an adapter plate 106, and a clamping member 107, and the lower end of the seven-degree-of-freedom mechanical arm 105 is fixed on a portable base through the adapter plate 106 . The two clamping parts 107 clamp the adapter plate 106 and the upper plate 201 of the portable base for stabilizing the seven-degree-of-freedom robot arm 105 .

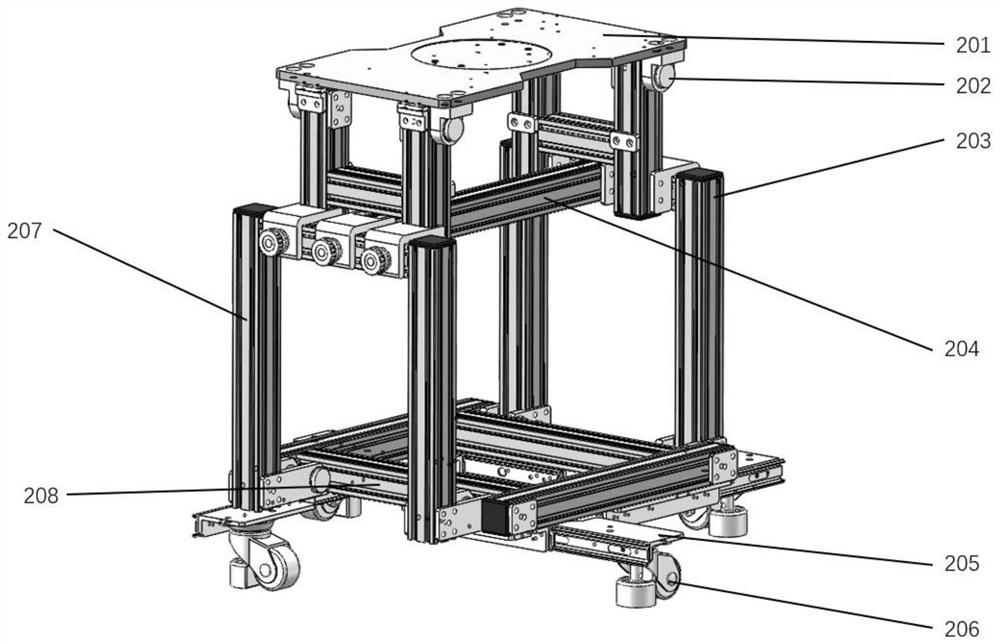

[0022] Such as figure 2 As shown, the portable base includes an upper and lower two-part structure, which is used to realize lifting and folding functions, meets the portable requirements of the base and can expand the measurement space range of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com