Elliptical hole machining device

A processing device and elliptical hole technology, which is applied to feeding devices, metal processing equipment, metal processing machinery parts, etc., can solve the problem that operators have high requirements for gas cutting skills, blind hole type elliptical holes cannot be processed, and affect the processing quality of elliptical holes, etc. problems, to achieve the effect of simple and convenient operation, fast equipment installation and layout, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

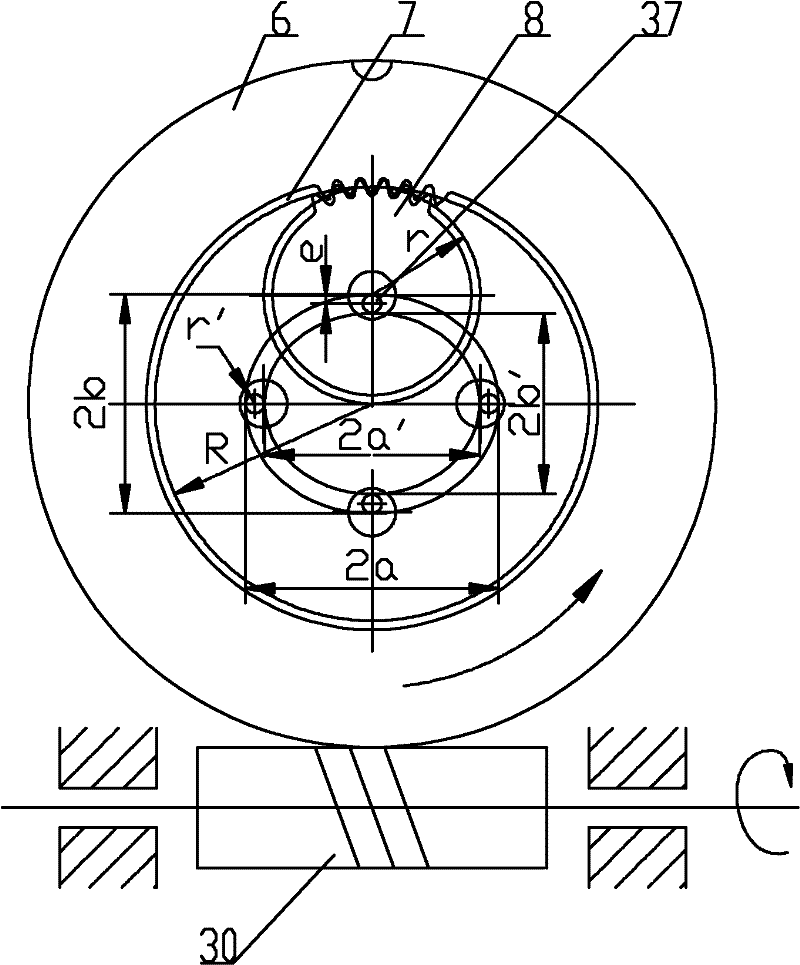

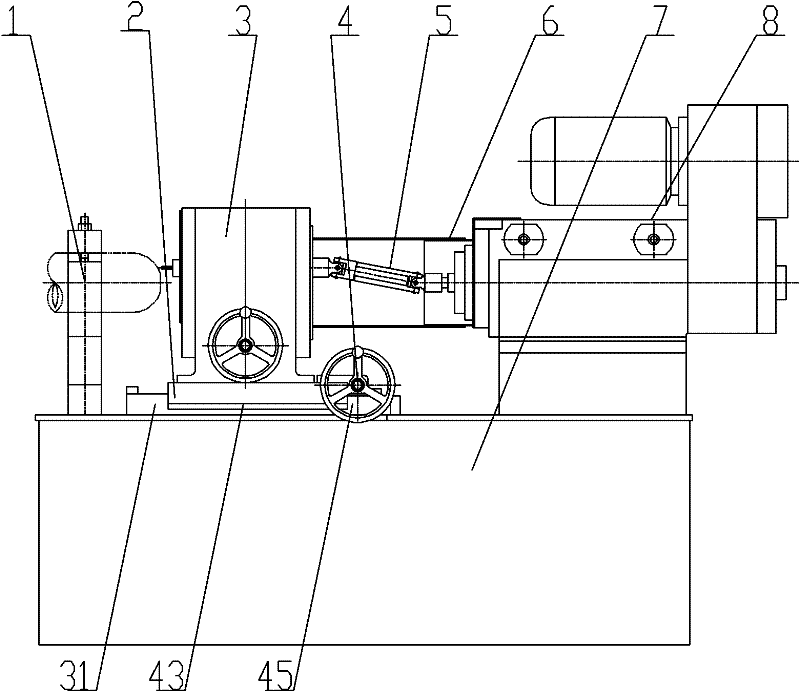

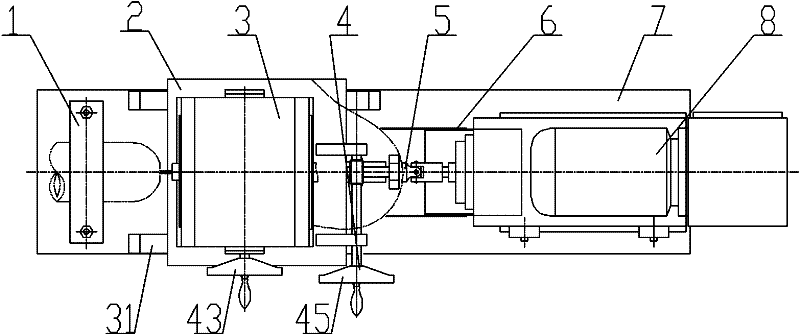

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] Such as Figure 2~Figure 5 As shown, the present invention is an oval hole processing device, which includes a seat frame 7 on which a workpiece clamping device 1 , a spindle box 3 and a power head 8 are arranged in sequence.

[0023] The workpiece clamping device 1 can be selected and adjusted according to the shape and length of the workpiece. In this embodiment, only the clamping device at the front of the workpiece of the pipe end necking type workpiece processing the elliptical hole at the end is shown. It includes a positioning block 39 on which a pressing plate 41 is threaded through a fastener 42 , and an adjusting backing plate 40 is arranged below the positioning block 39 . The V-shaped groove of the positioning block 39 is used for positioning, and the adjusting backing plate 40 of different thickness is inserted, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com