Operation frame platform facility for building elevator construction

A technology for operating racks and elevators, which is applied in the directions of buildings, building structures, scaffolding accessories, etc., can solve the problems of poor adjustment effect, high use limitations, and cumbersome erection process, etc., to achieve the effect of height adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

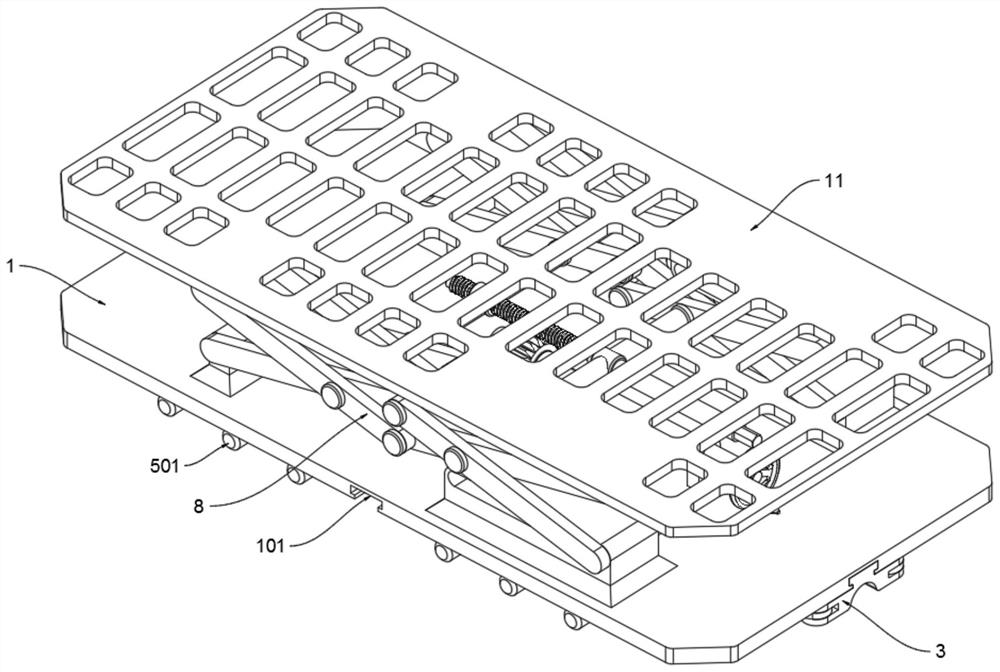

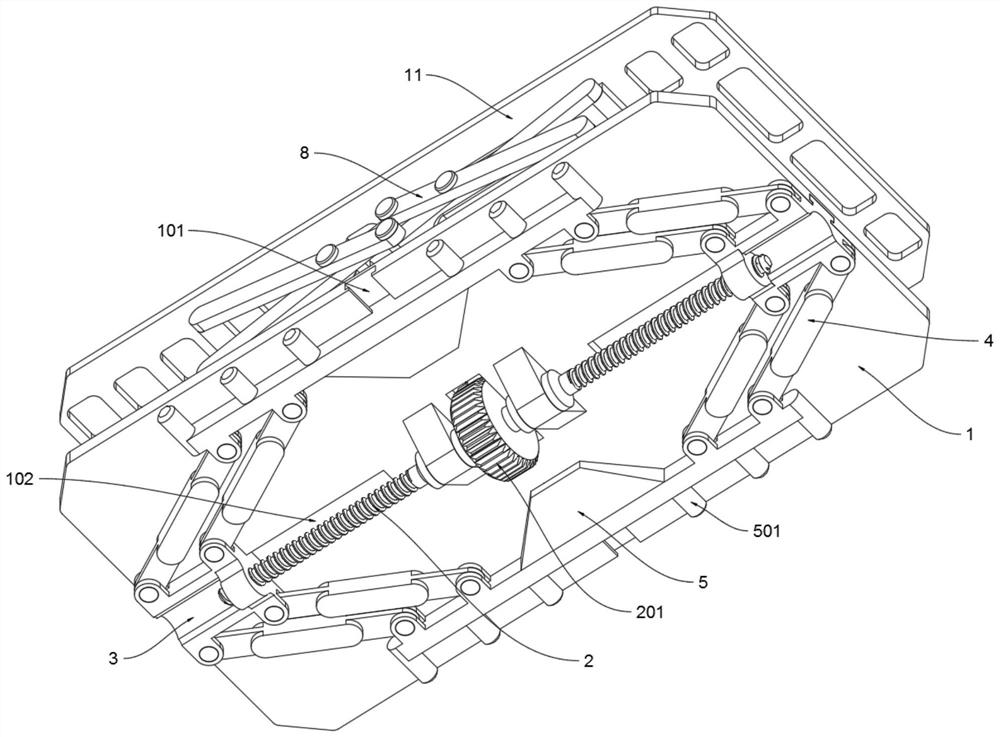

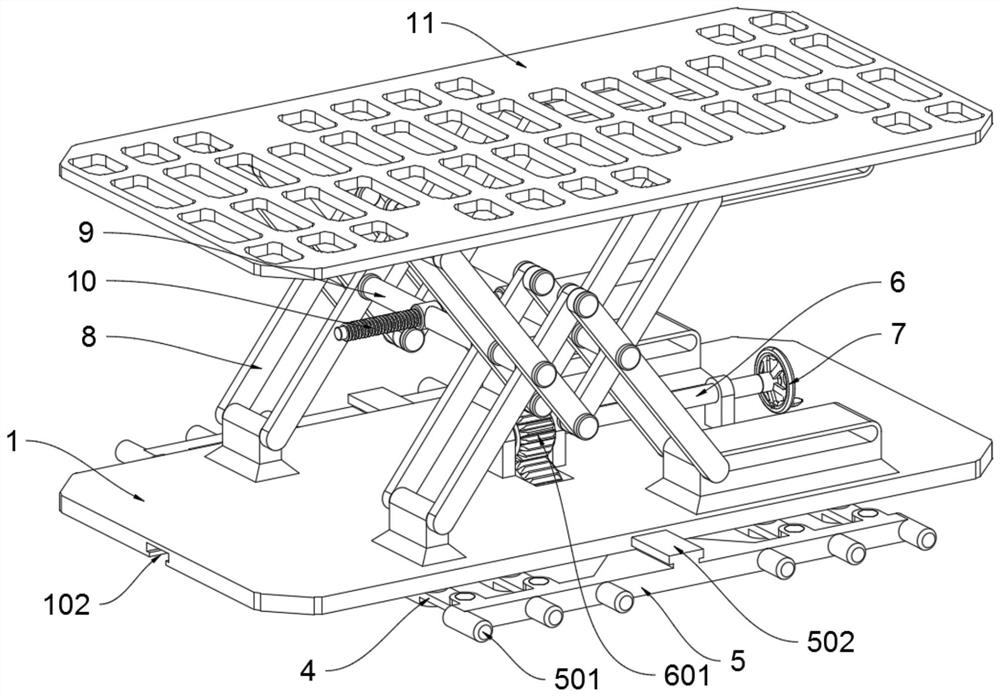

[0041] as attached figure 1 to attach Figure 7 Shown:

[0042] The present invention provides an operating frame platform facility for building elevator construction, which includes a base 1, a movable support rod 5 and a construction support plate 11;

[0043] A drive mechanism A is connected to the bottom of the base 1, and the drive mechanism A is connected to the handwheel 7;

[0044] A limit chute 101 is respectively provided at the left and right ends of the bottom side of the base 1, and a guide chute 102 is respectively provided at the front and rear ends of the bottom side of the base 1;

[0045] The movable support rod 5 is provided with two left and right places, and the movable support rod 5 is connected to the bottom side of the base 1;

[0046] The top of the movable support rod 5 is provided with a limit slider 502, and the limit slider 502 at the top of the movable support rod 5 is slidably connected to the limit chute 101 at both ends of the bottom side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com