Cellar treading and cellar lifting integrated equipment for strong-flavor white white spirit cellar

A technology of strong-flavor liquor and stepping on the cellar is applied in the preparation, loading/unloading, conveyor and other directions of alcoholic beverages. The effect of reducing labor intensity and improving wine production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

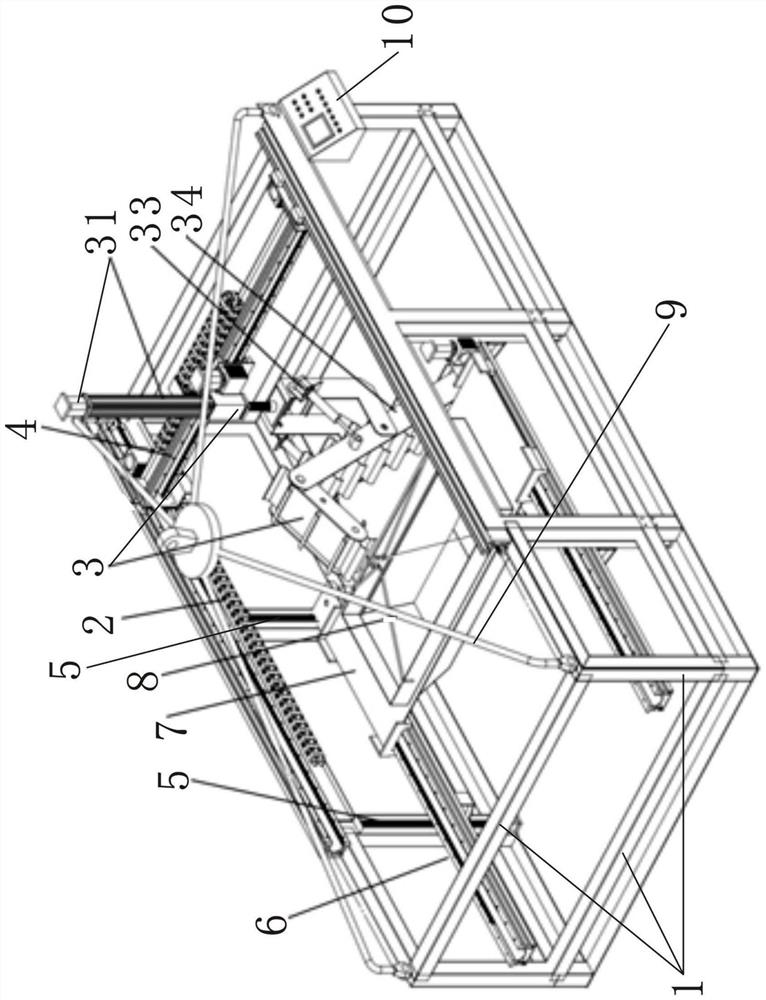

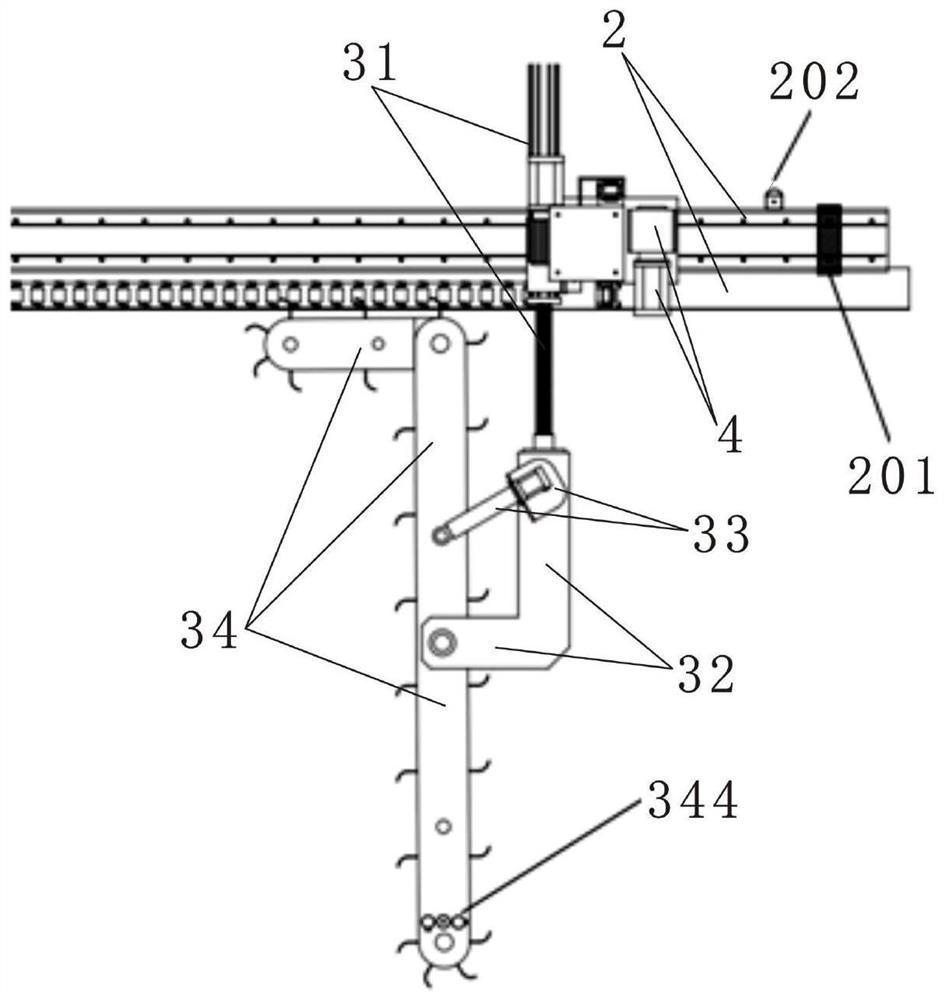

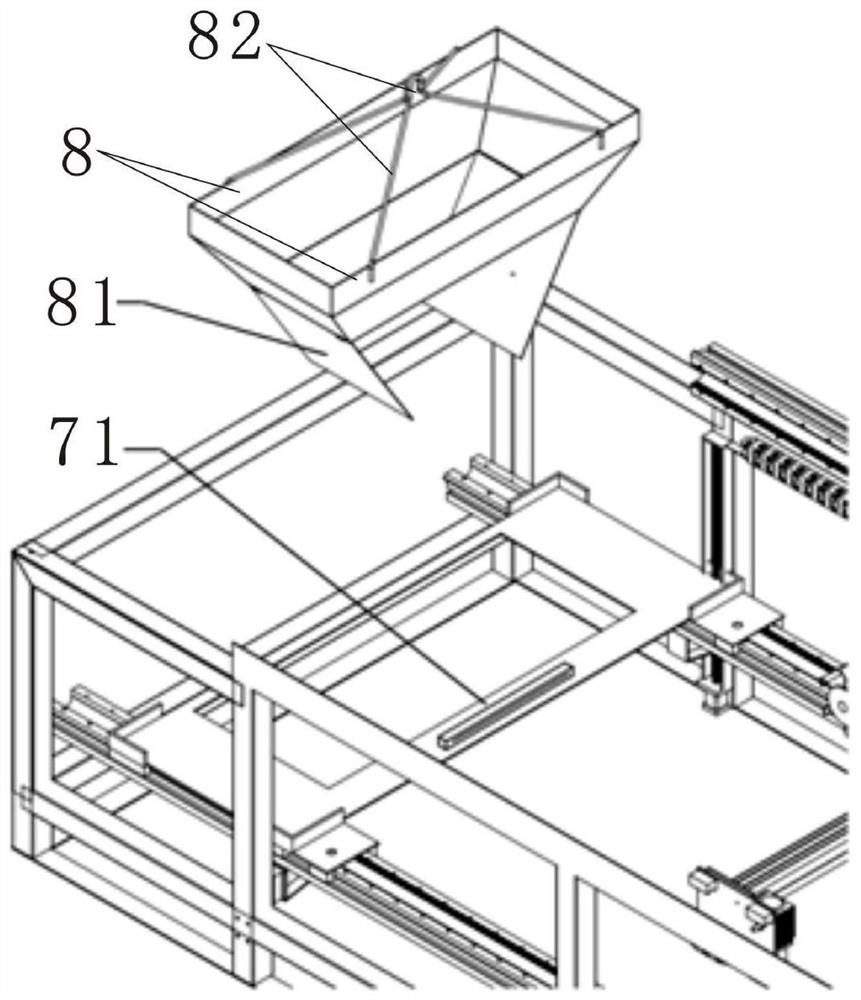

[0040]Such asFigure 1 ~ Figure 13 As shown, an integrated device for stepping and lifting the cellar of a strong-flavor liquor cellar includes a frame 1, a layered squeezing unit 3 and a material hopper 8. The upper two sides of the frame 1 are respectively provided with a squeezing unit lateral movement mechanism 2. The longitudinal moving mechanism 4 of the squeezing unit is slidably installed between the two transverse moving mechanisms 2 of the squeezing unit, and the longitudinal moving mechanism 4 of the squeezing unit is slidably installed between the two transverse moving mechanisms 2 of the squeezing unit. The transverse moving mechanism 2 of the pit unit synchronously drives the longitudinal moving mechanism 4 of the pitting unit to move laterally, so as to facilitate the lateral movement of the layered pitting unit 3 to a suitable position. The longitudinal movement mechanism 4 of the decay unit is vertically slidably installed with the layered decay unit 3, and the longi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com