Multi-stage Quantitative Melting Furnace for Medical Titanium Alloy

A smelting furnace and titanium alloy technology, applied in the field of titanium alloys, can solve problems such as insufficient efficiency, insufficient time and speed of addition, product strength and stiffness not reaching the refining index, etc., to achieve the effect of increasing efficiency and preventing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

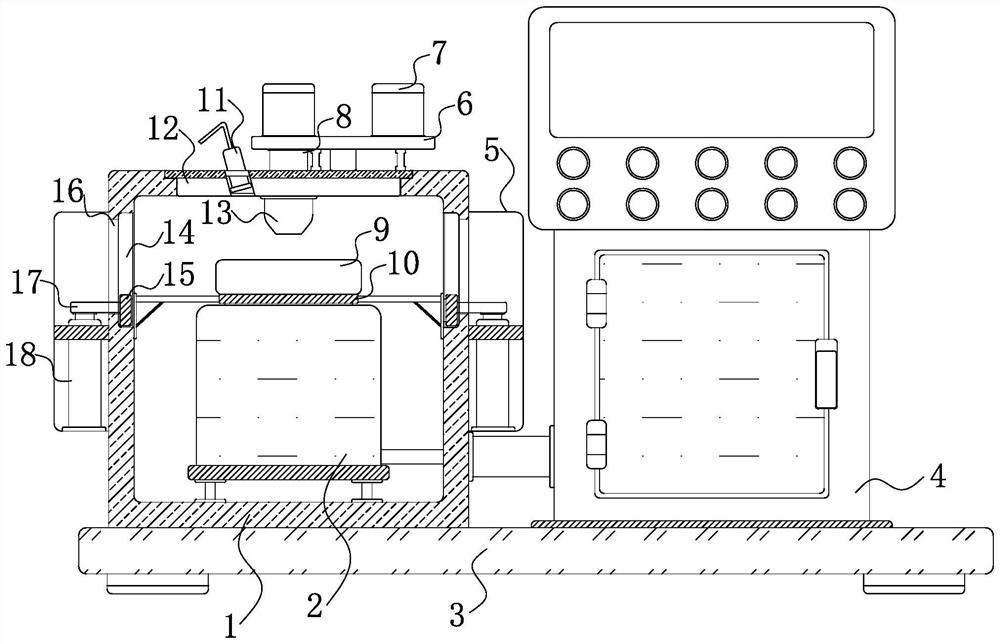

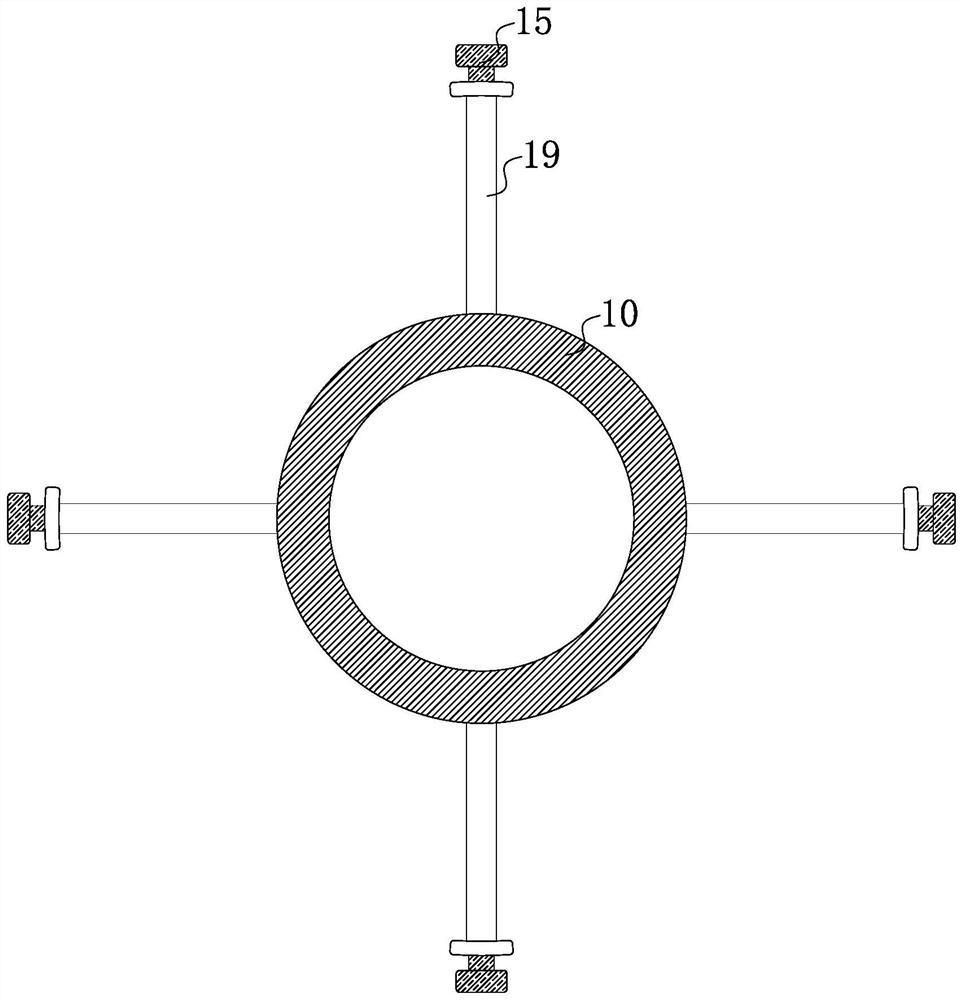

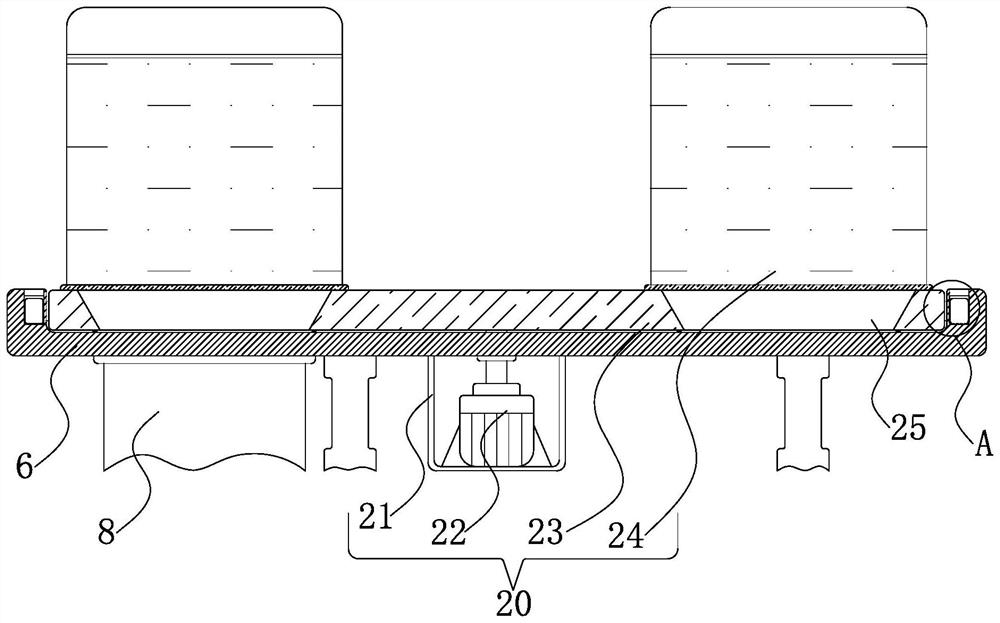

[0028] Such as Figure 1-7 As shown, the medical titanium alloy multi-stage quantitative melting furnace includes a working base plate 3, and a controller 4 is arranged on the right side of the upper end of the working base plate 3. In this embodiment, the model of the controller 4 is HT-7220GSM, and the upper end of the working base plate 3 is left. A smelting frame 1 is arranged on the side, and an electric control heating frame 2 is arranged at the inner bottom of the smelting frame 1, and an annular electric control heating tube is arranged inside the electric control heating frame 2, and the right end of the annular electric control heating tube passes through the smelting frame 1 and the control The device 4 is electrically connected, the upper end of the smelting frame 1 is provided with a melting crucible 9, the middle part of the upper end of the smelting fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com