Cable toughness detection equipment

A technology of testing equipment and toughness, which is applied in the field of testing equipment, can solve problems such as the inability to guarantee the safety of operators and lack of safety protection, and achieve the effect of avoiding damage to equipment and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

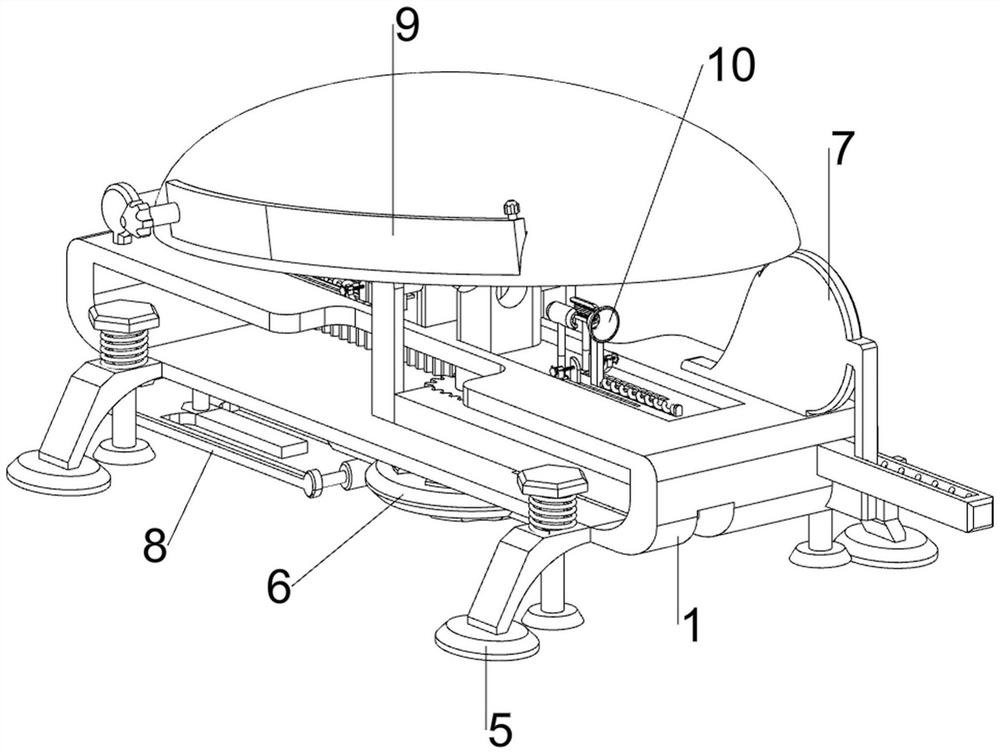

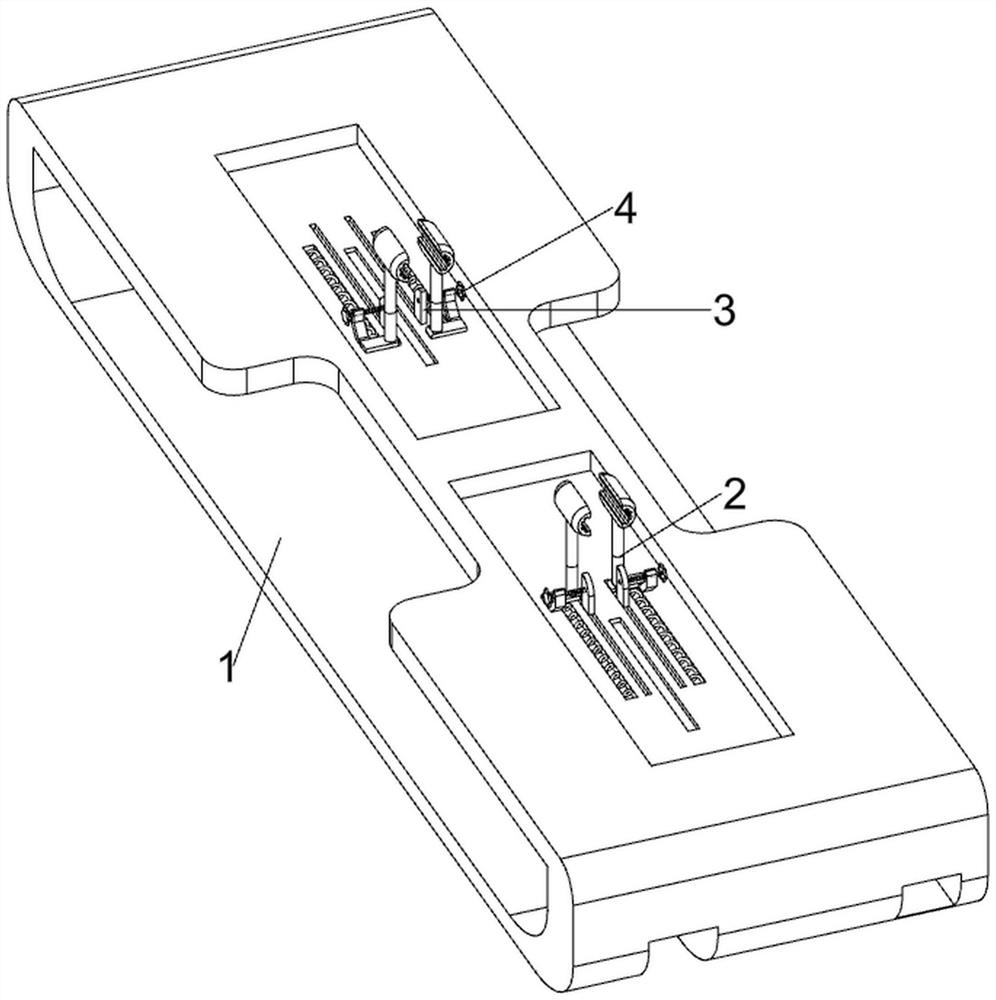

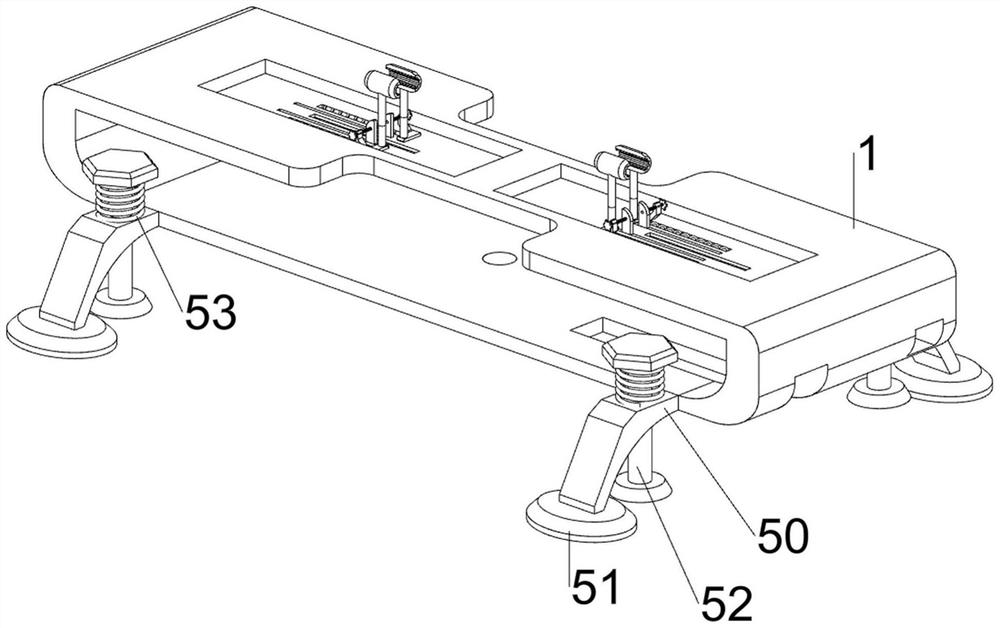

[0026] A cable toughness testing equipment, such as Figure 1-8 As shown, it includes a mounting plate 1, a clamping device 2, a perforated plate 3, a bolt 4, a fixing mechanism 5 and an automatic pulling mechanism 6. The left and right sides of the top of the mounting plate 1 are symmetrically connected with sliding posts, and the tops of the sliding posts are connected symmetrically. The clamper 2 is slidingly connected, and springs are provided between the clamper 2 and the mounting plate 1. The left and right sides of the top of the mounting plate 1 are symmetrically slidably connected with the perforated plate 3, and the perforated plate 3 is located at the clamping position. Between the devices 2, bolts 4 are rotatably connected on the perforated plate 3, and the bolts 4 are threadedly connected with the clamper 2. The mounting plate 1 is provided with a fixing mechanism 5, and the mounting plate 1 is provided with an automatic pulling mechanism 6.

[0027] The fixing me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com