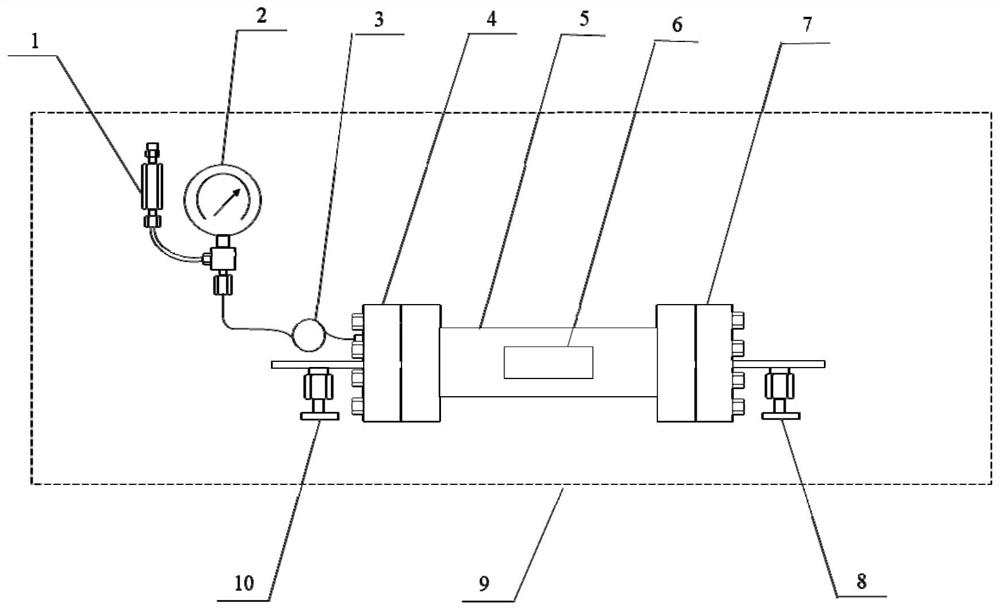

Device for evaluating tolerance of gel natural gas in high-temperature and high-pressure environment and method thereof

A high-temperature, high-pressure, evaluation device technology, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as difficult to simulate the long-term dynamic coexistence environment of high temperature and high pressure gas in gas injection wells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

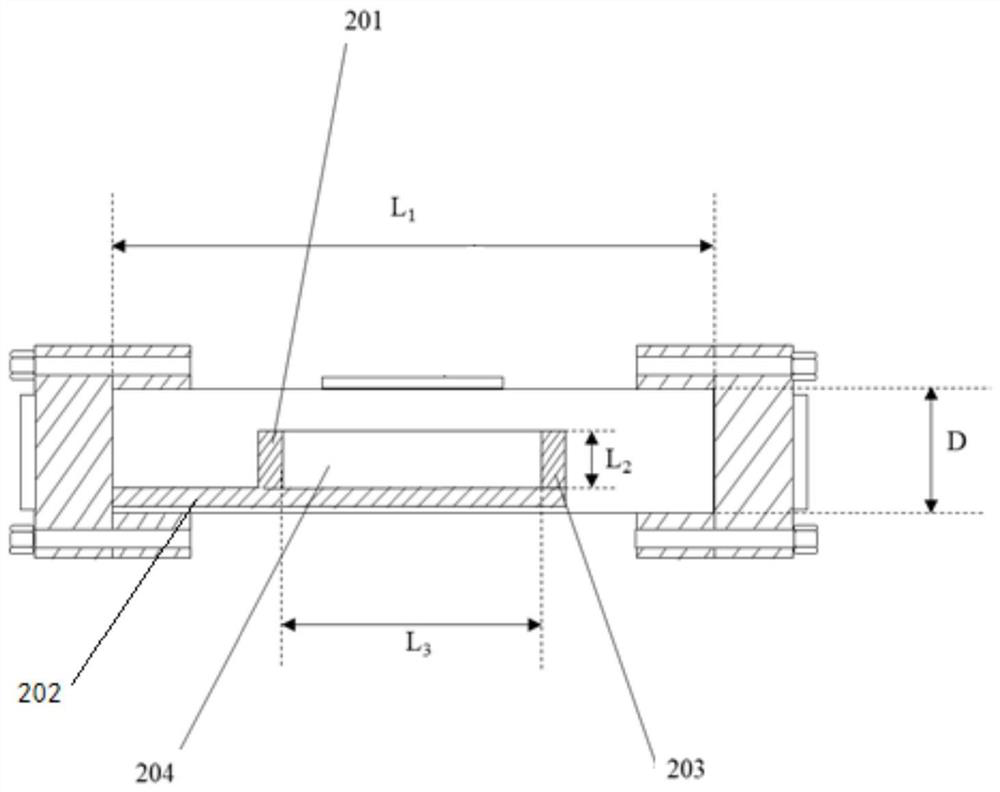

Method used

Image

Examples

Embodiment 1

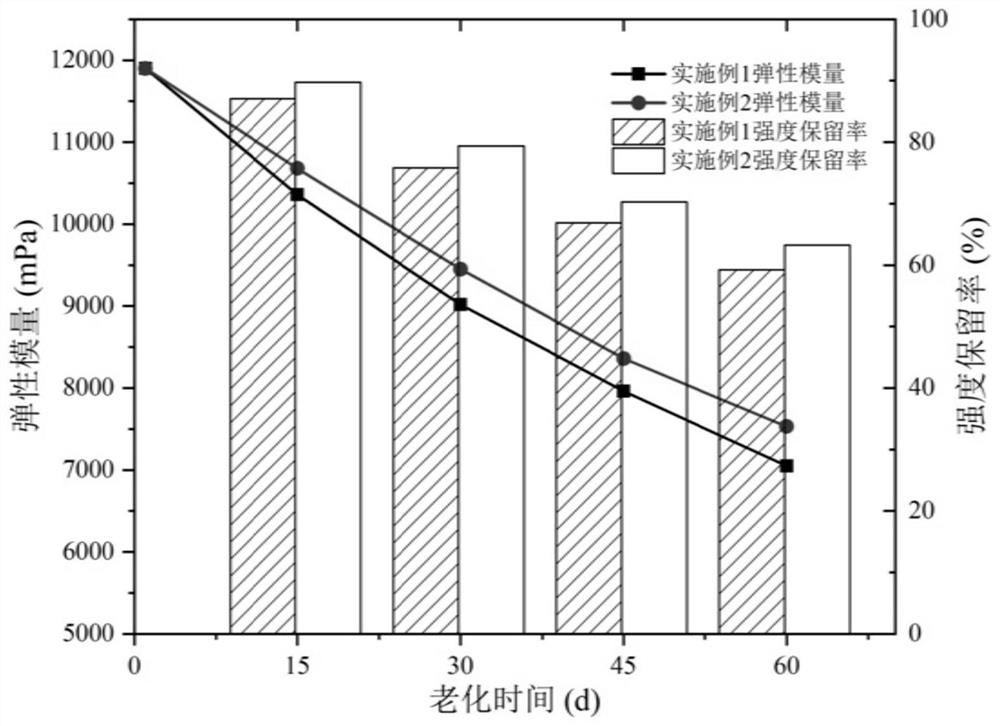

[0097] Add 0.8g of polyacrylamide, 0.3g of urotropine, 0.3g of resorcinol, and 0.4g of stabilizer in sequence while stirring in 98.2g of simulated seawater, and keep stirring until uniform to obtain a gelling solution of the profile control system. Its composition is 0.8% polyacrylamide, 0.3% urotropine, 0.3% resorcinol, 0.4% high temperature stabilizer and 98.2% simulated seawater in terms of mass fraction. After gelling at a high temperature of 120°C for 24 hours, the evaluation was carried out according to steps S1-S8. The evaluation device was fed with natural gas, the experimental temperature was 120°C, and the pressure was 20MPa. The performance of the gel was measured every 15 days, and the retention rate of the gel strength was calculated. Elastic modulus after aging for different times / Elastic modulus after 24 hours of gelling.

Embodiment 2

[0099] Add 0.8g of polyacrylamide, 0.3g of urotropine, 0.3g of resorcinol, and 0.4g of stabilizer in sequence while stirring in 98.2g of simulated seawater, and keep stirring until uniform to obtain a gelling solution of the profile control system. Its composition is 0.8% polyacrylamide, 0.3% urotropine, 0.3% resorcinol, 0.4% high temperature stabilizer and 98.2% simulated seawater in terms of mass fraction. After gelling at 120°C for 24 hours, the evaluation is carried out according to steps S1-S8, but simulated water is introduced into the evaluation device, the experimental temperature is 120°C, and the pressure is 20MPa. The performance of the gel is measured every 15 days, and the strength retention of the gel is calculated. The ratio is elastic modulus after aging for different times / elastic modulus after 24 hours of gelation.

[0100] Embodiment 1,2 evaluation result is as image 3 shown.

[0101] This technical solution provides an evaluation device and method for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com