Belt tearing detection device

A detection device and belt technology, used in measurement devices, optical testing of flaws/defects, material analysis by optical means, etc., can solve problems such as poor flexibility of use, economic loss, and cumbersome detection, and achieve increased collection space range, convenience Fast Accuracy, Improved Precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

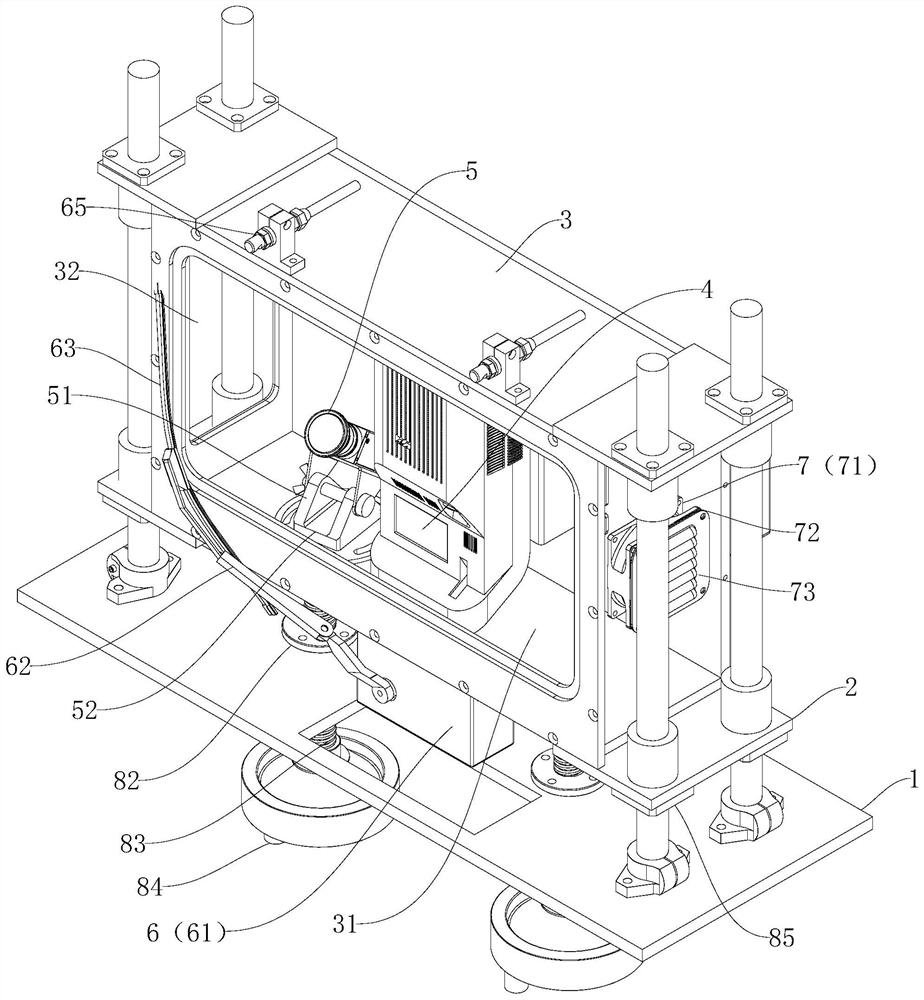

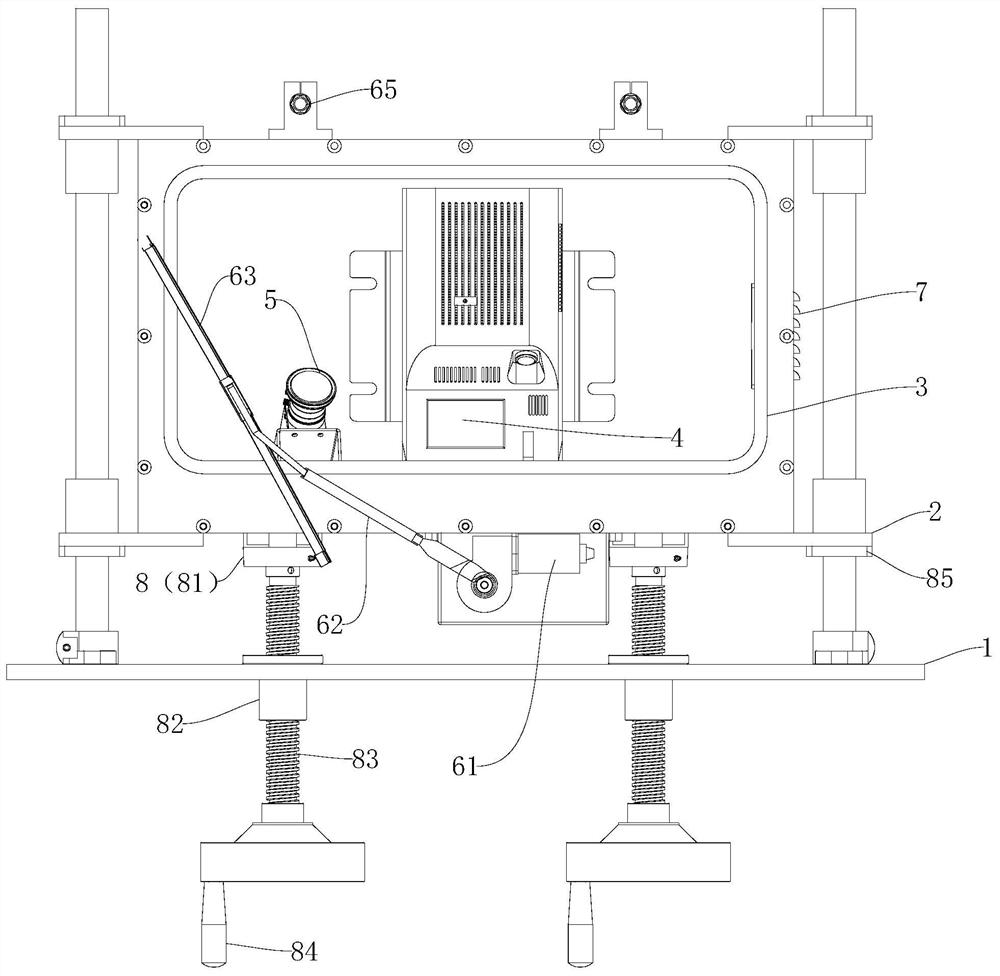

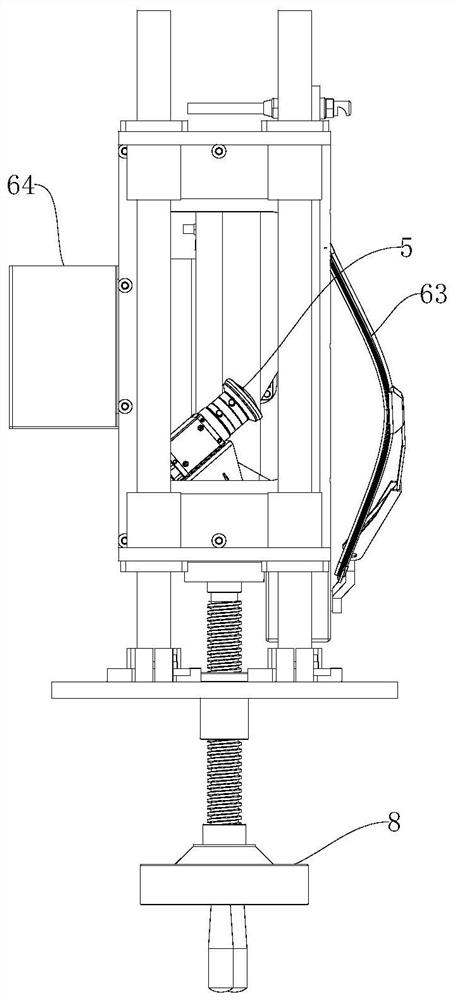

[0033] Such as figure 1 and figure 2 As shown, the belt tear detection device of this embodiment is installed between the belts arranged up and down as a whole, and specifically includes a mounting plate 2 and a housing 3 located on the mounting plate 2 and having a housing cavity, and the mounting plate 2 in the housing cavity It is provided with a light source emitting unit 4 for emitting a light beam to the belt and a camera 5 (such as an industrial camera 5) for catching the light source on the belt. glass); the mounting plate 2 is provided with a cloud platform, and the camera 5 is installed on the mounting plate 2 through the cloud platform to realize horizontal rotation and vertical angle adjustment; in addition, the transparent plate 31 is provided with a cleaning unit 6.

[0034] The belt tear detection device of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com