Service life evaluation device and method for pre-filter filter element for condensate polishing

A technology of condensate polishing and pre-filter, which is applied in the testing of measuring devices, instruments, machines/structural components, etc., and can solve the problems that filter elements cannot provide strong evidence and waste money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The patent of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

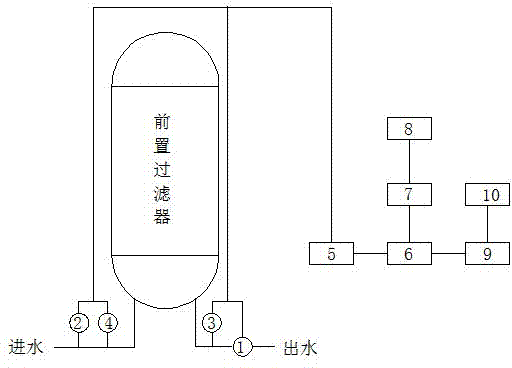

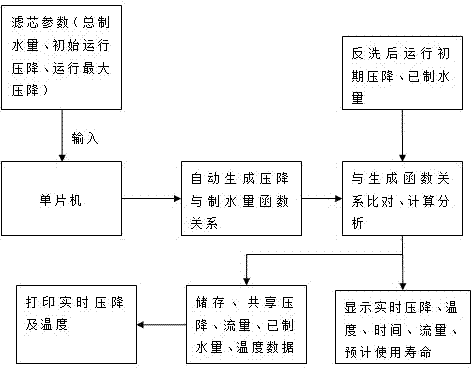

[0021] see figure 1 , flow meter (1), temperature sensor (2), pressure gauge one (3), pressure gauge two (4), signal converter (5), microcontroller (6), display controller (7), display (8) , computer (9), printer (10), the flowmeter (1) and pressure gauge one (3) are installed on the pre-filter outlet pipe, the temperature sensor (2) and pressure gauge two (4) are installed On the water inlet pipeline of the pre-filter, the flowmeter (1), temperature sensor (2), pressure gauge one (3), pressure gauge two (4) are connected to the signal converter (5), and the signal converter (5) Connected to the single-chip microcomputer (6), the single-chip microcomputer (6) is connected to the display controller (7) and the computer (9), the display controller (7) is connected to the display (8), and the computer (9) ) is connected with the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com