Manual energy storage device and circuit breaker

A technology of energy storage device and energy storage shaft, which is applied to the power device, circuit, electrical components and other directions inside the switch, can solve the problems of ratchet and thrust pawl damage, short mechanical service life, ratchet tooth wear, etc. , The overall structure is compact and stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

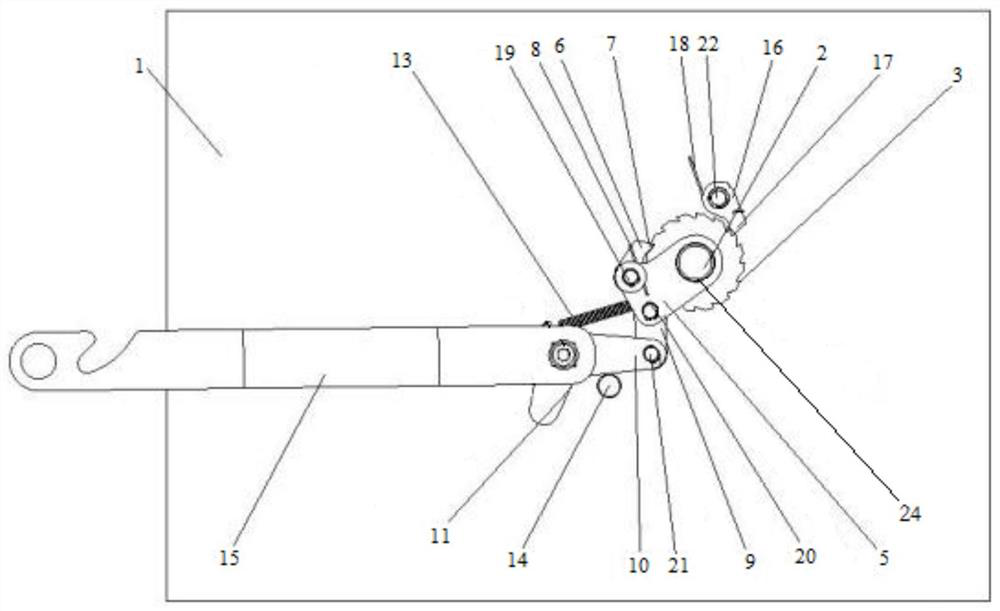

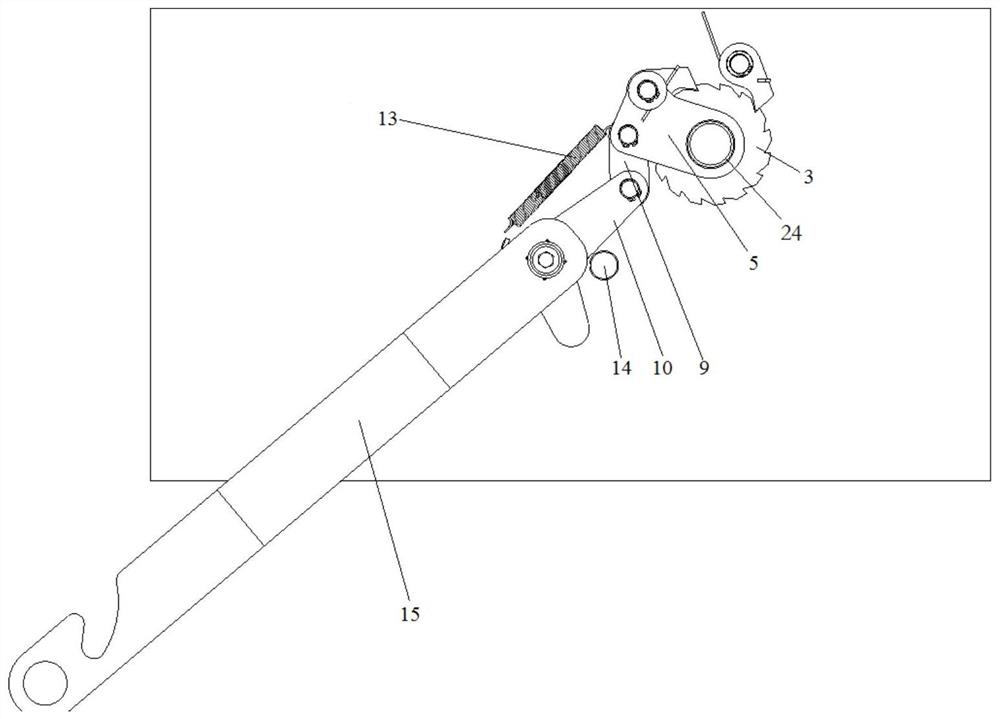

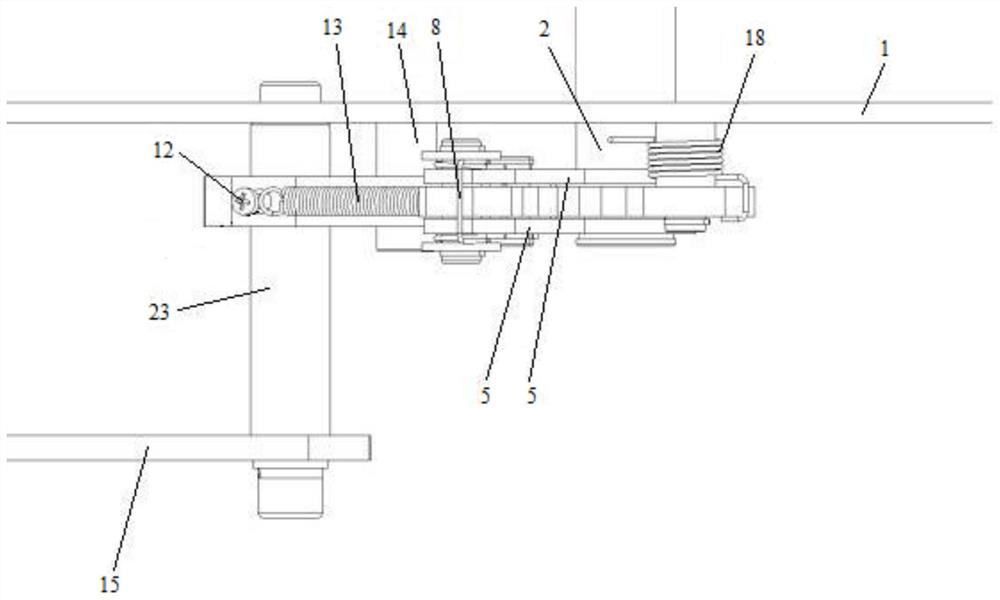

[0065] This embodiment provides a manual energy storage device, such as figure 1 , figure 2 , image 3 shown, including:

[0066] The installation plate 1 is provided with several installation holes for installing the subsequent energy storage shaft 2 , limit pin 14 , fourth pin 22 and fixed shaft 23 .

[0067] The energy storage shaft 2, the energy storage shaft 2 is rotatably mounted on the installation plate 1, the energy storage shaft 2 is connected to the intermediate transmission mechanism, and the rotation of the energy storage shaft 2 drives the intermediate transmission mechanism inside the circuit breaker , and finally realize the energy storage operation of the circuit breaker.

[0068] Ratchet 3, such as Figure 4 As shown, the ratchet 3 is disc-shaped, and ratchets are arranged on the circumference, and the ratchets cooperate with the subsequent thrust pawl 6 and limit pawl 16 to push the ratchet 3 to rotate and limit the ratchet 3 turn.

[0069] A through...

Embodiment 2

[0102] This embodiment provides a circuit breaker, including:

[0103] The base housing provides accommodating space and installation positions for the subsequent installation of the intermediate transmission mechanism, closing and opening mechanism, and manual energy storage device.

[0104] The intermediate transmission mechanism, the energy storage shaft 2 drives the intermediate transmission mechanism to make the energy storage spring act to realize the energy storage operation of the circuit breaker.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com