Rail electricity taking vehicle

A track and trolley technology, applied to circuits, electrical components, conveyors, etc., can solve problems such as inflexible use, low production efficiency, and heavy concrete products, and achieve the effect of simple overall structure, flexible use, and smooth running

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

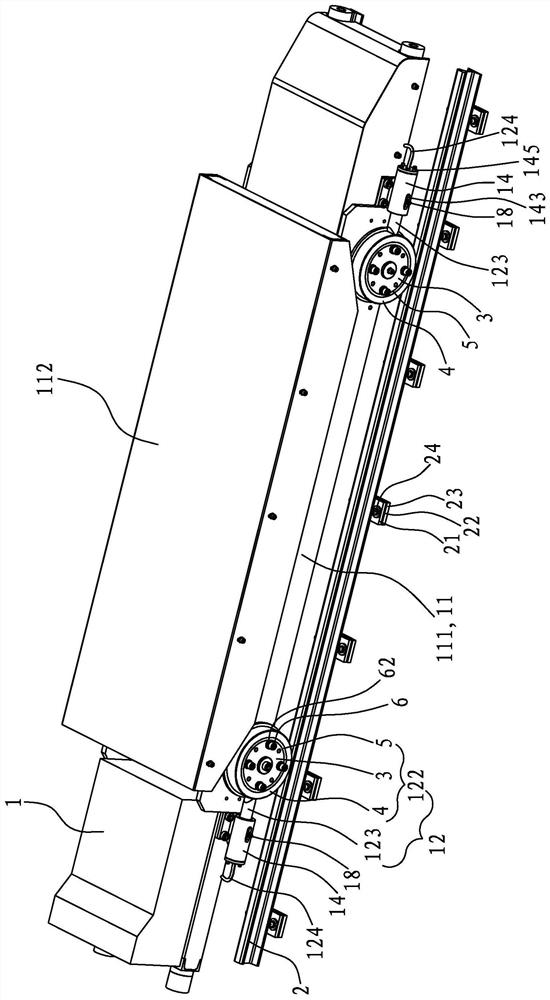

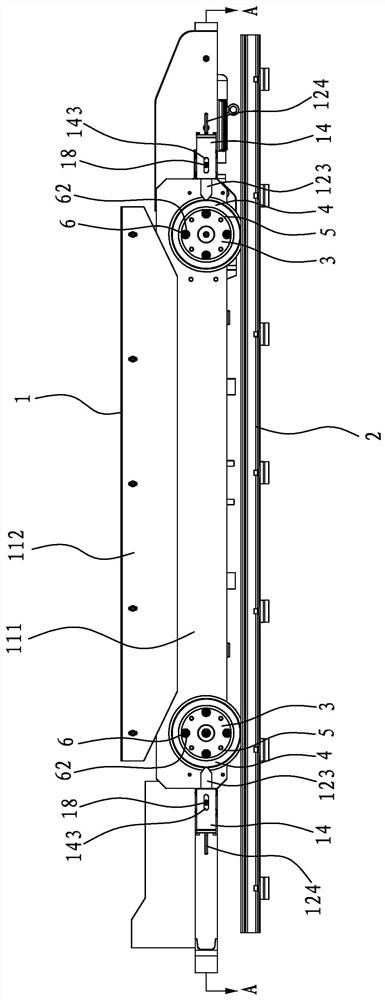

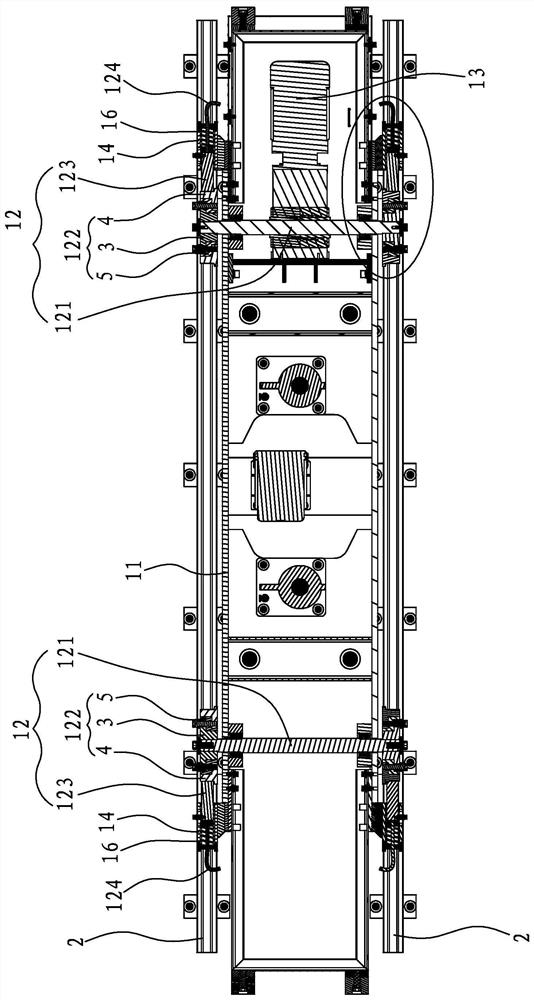

[0047] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

[0048] see Figure 1 to Figure 5 , the present invention discloses a rail-taking trolley, the rail-taking tram 1 walks on two rails 2, wherein one rail 2 is connected to a positive voltage, and the other rail 2 is connected to a negative voltage; the rail-taking tram 1 includes a frame 11. Two sets of walking wheel sets 12 arranged at both ends of the bottom of the vehicle frame 11 and a drive motor 13 for driving at least one set of walking wheel sets 12; each set of walking wheel sets 12 has a main shaft pivotally connected to the vehicle frame 11 121. Two walking wheels 122 located at both ends of the main shaft 121 and two electric pick-up rods 123 respectively abutting against the two walking wheels 122, the walking wheels 122 have inner rollers 3, outer rollers 4 and isolate inner rollers 3 and outer roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com