Variable-diameter throttling orifice plate

A technology of orifice plate and orifice, which is applied in the direction of pipe components, mechanical equipment, pipes/pipe joints/pipe fittings, etc., can solve the problem of time-consuming and laborious disassembly, re-processing and installation of the orifice plate for many times, and avoid the The effect of multiple disassembly, reprocessing and installation to improve test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

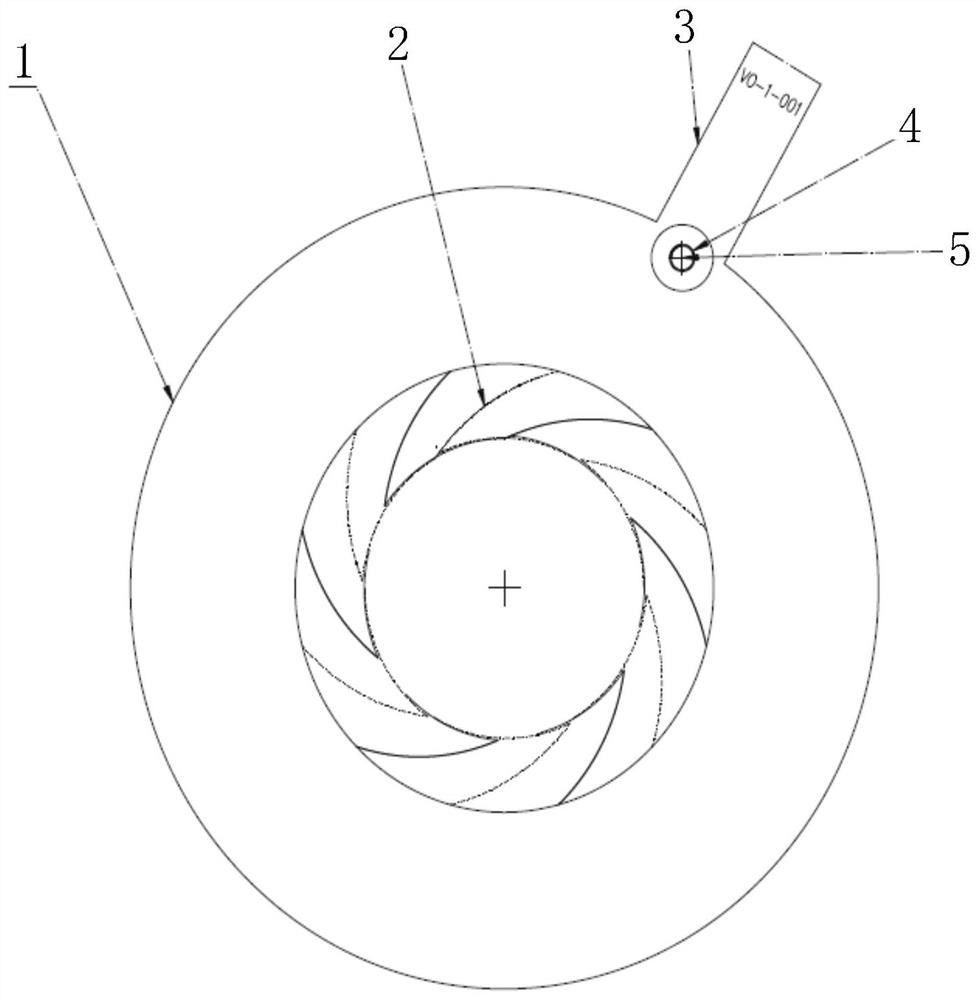

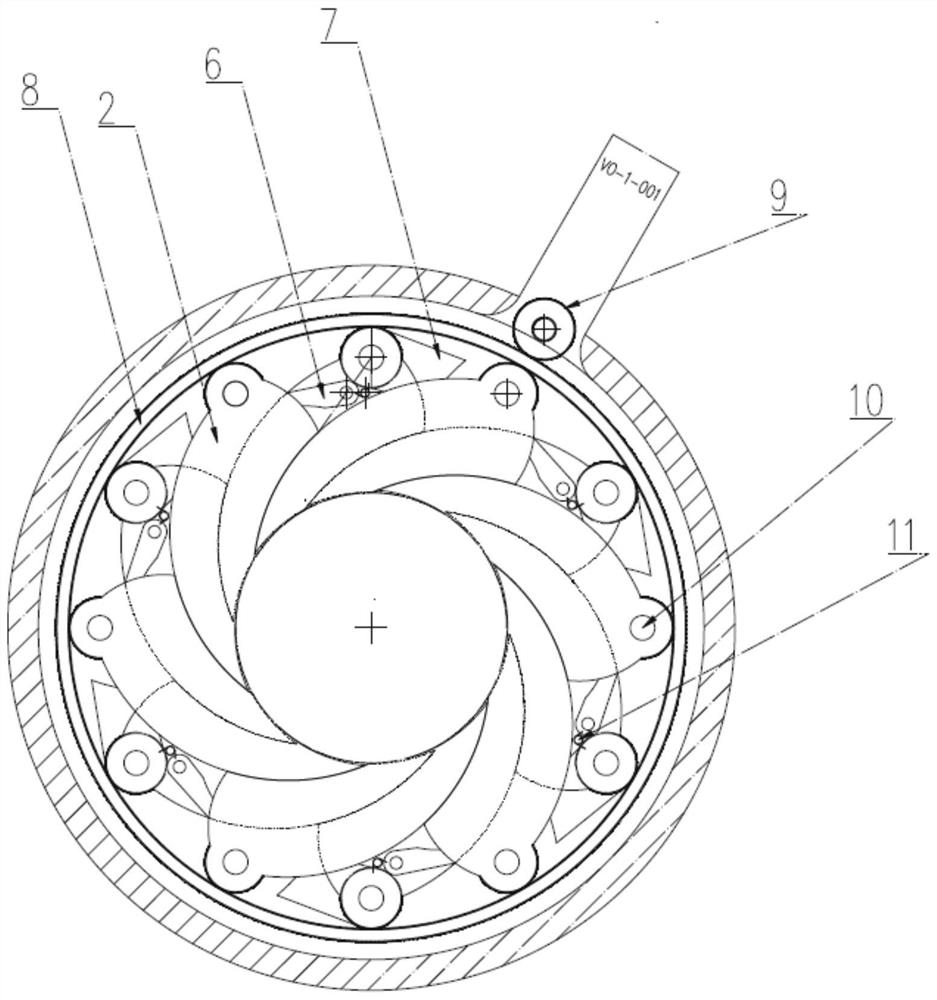

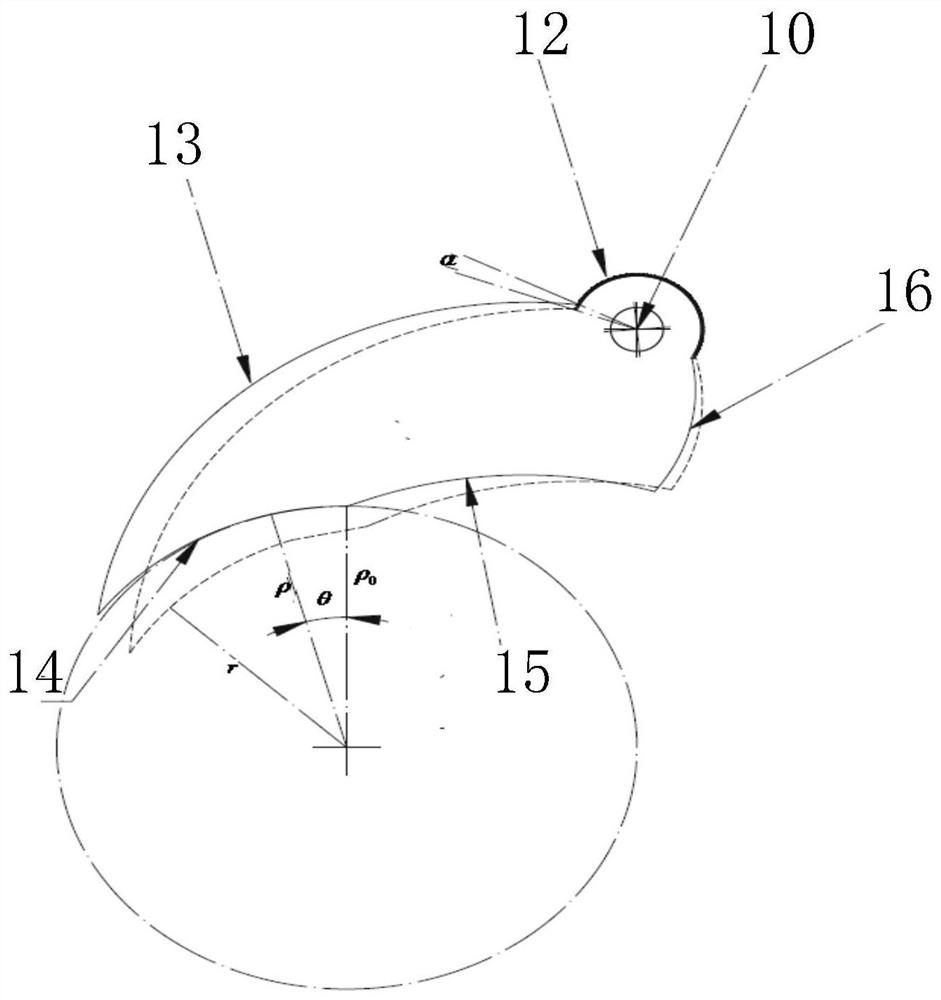

[0067] In order to solve the technical problem existing in the prior art that the throttling orifice needs to be dismantled and reprocessed multiple times to install the throttling orifice in the process of accurately designing the throttling orifice, the embodiment of the present invention provides a variable-diameter throttle orifice. Figure 1-Figure 7 As shown, the variable-diameter orifice plate includes: a mounting plate 1, which is provided with several aperture adjustment plates 2 for rotation; several aperture adjustment plates, and the second forming surfaces 14 of all aperture adjustment plates jointly form a circular shape. An orifice; and a transmission mechanism, which is in transmission connection with each aperture adjusting plate, and is used to synchronously change the rotation angle of each aperture adjusting plate to change the diameter of the orifice.

[0068] Therefore, by adjusting the rotation angle of each aperture adjustment plate, the adjustment of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com