Optical lens assembly and lighting device

A lighting device and component technology, applied in the direction of lenses, optical components, optics, etc., can solve the problems of loss of light efficiency, low light efficiency, high cost, etc., and achieve the effects of reducing processing costs, improving light efficiency, and preventing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

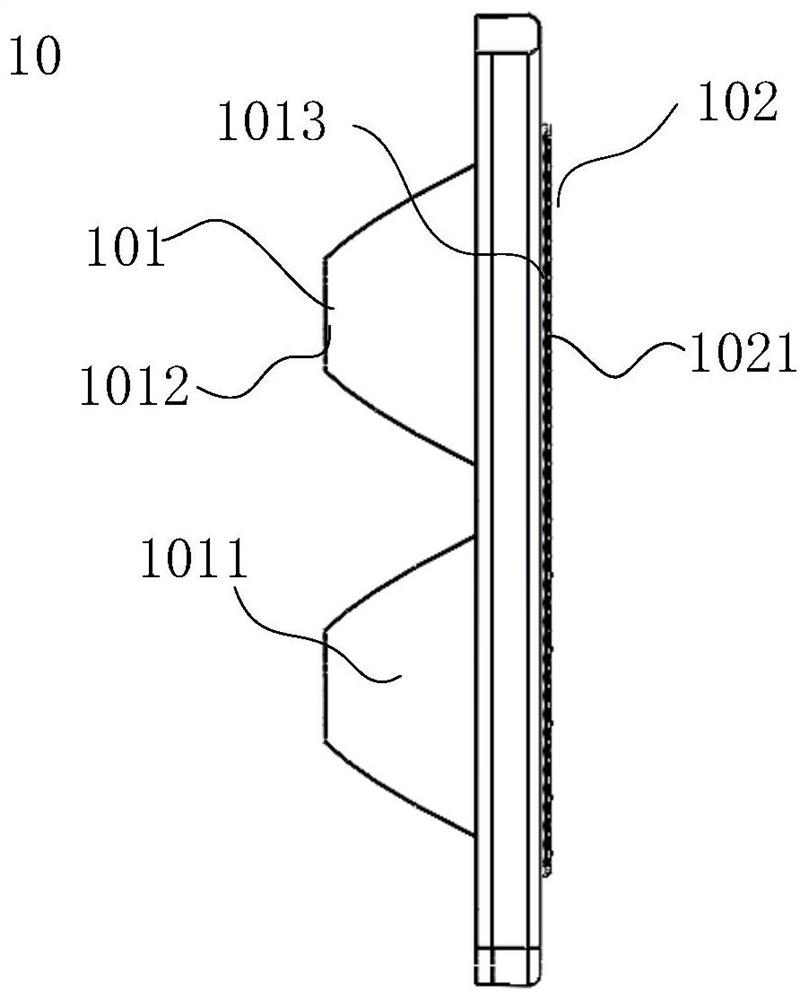

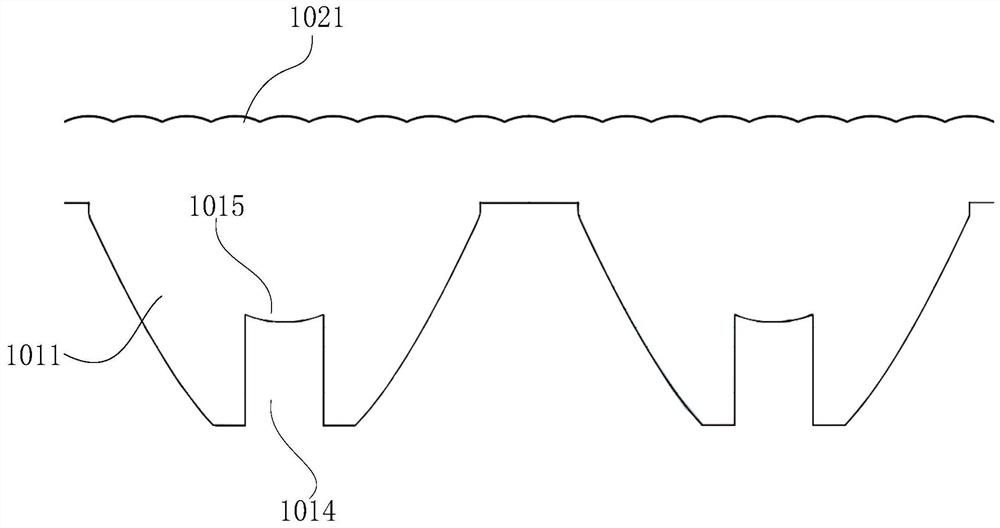

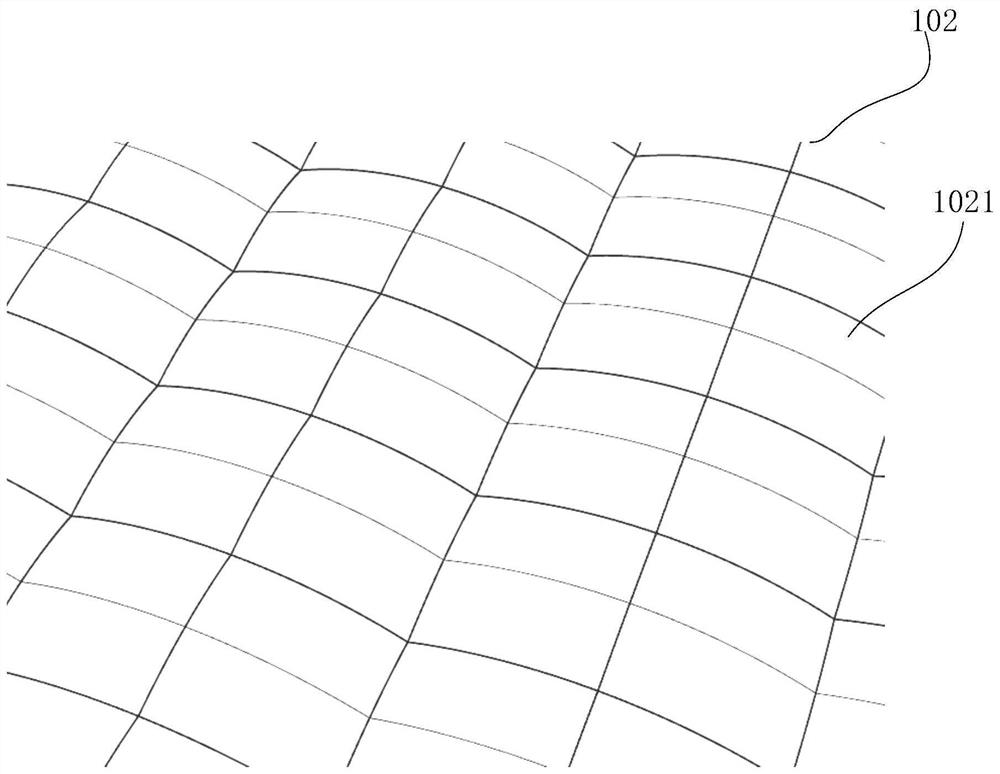

[0036] See Figure 1 to 5 As shown, the light lens assembly 10 in the present embodiment includes a ratio direct lens unit 101 and a complementary eye lens unit 102, and the collimated lens unit 101 is collimated to the light beam emitted by the light source 20, and the complex eye lens unit 102 will be collimated. The processed beam is divided.

[0037] Among them, the collimation process is: the light beam emitted by the light source 20 causes the light beam to disperse, and thereby causing the energy dispersed of the beam, the collimating lens unit 101 is quasi-dispersed to collect energy. The segmentation process is that the complex eye lens unit 102 re-segments the energy of the beam into it in accordance with the desired demand of the final imaging to reselect a few small light sources.

[0038] In the prior art, the collimated lens unit 101 and the complementary eye lens unit 102 are separately disposed such that the light beam after the collimated lens unit 101 processes th...

Embodiment 2

[0049] See figure 1 with Image 6 As shown, the illumination device 100 in this embodiment includes a light source 20, a light lens assembly 10, and a receiving assembly 30, and the light beam emitted by the light source 20 is received after the receiving assembly 30 is received. Among them, the light lens assembly 10 is the light lens assembly 10 shown in Example 1. It is disposed on one side of the light source 20 for collimating and segmenting the light beam of the light source 20. In the present embodiment, the light source 20 is an LED, and the receiving assembly 30 is an LCD.

[0050] The illumination device 100 in the prior art is provided with integral lens assemblies between the light lens assembly 10 and the receiving assembly 30, and the integral lens assembly includes several integral lenses, several integral lenses will be formed by the complex eye lens unit 102. A small light source 20 is superimposed to the receiving assembly 30 to form uniform lighting. However, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap