Laser cutting machine applied to special-shaped sheet metal parts

A laser cutting machine and laser cutting head technology, applied in laser welding equipment, metal processing equipment, welding equipment and other directions, can solve the problems of serious loss and large gas consumption of shielding gas, and achieve the effect of saving gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further elaborated below by means of the accompanying drawings and examples.

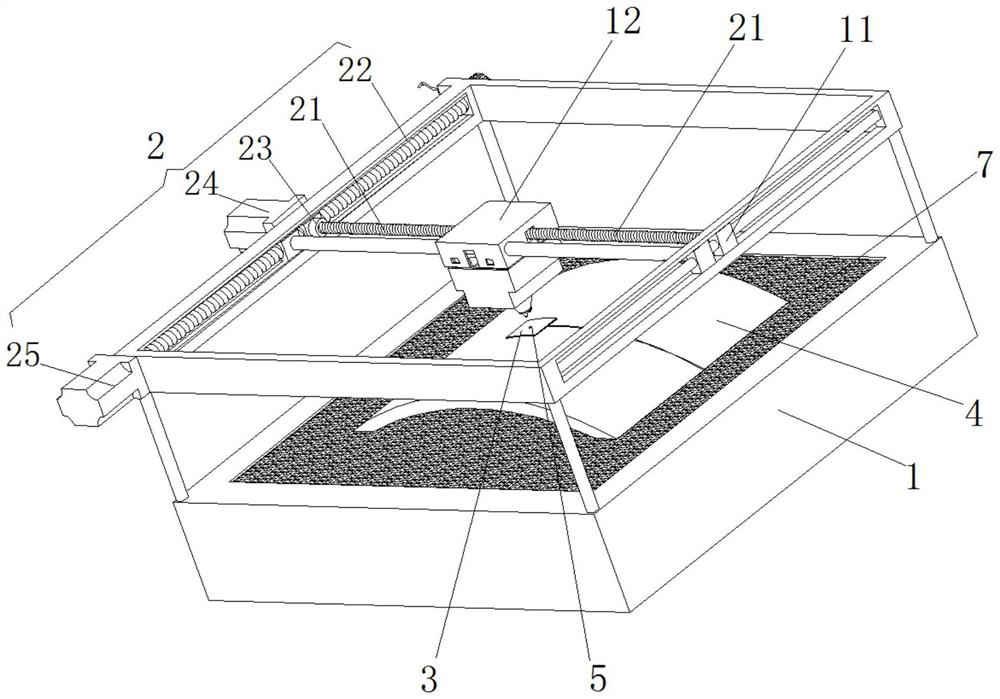

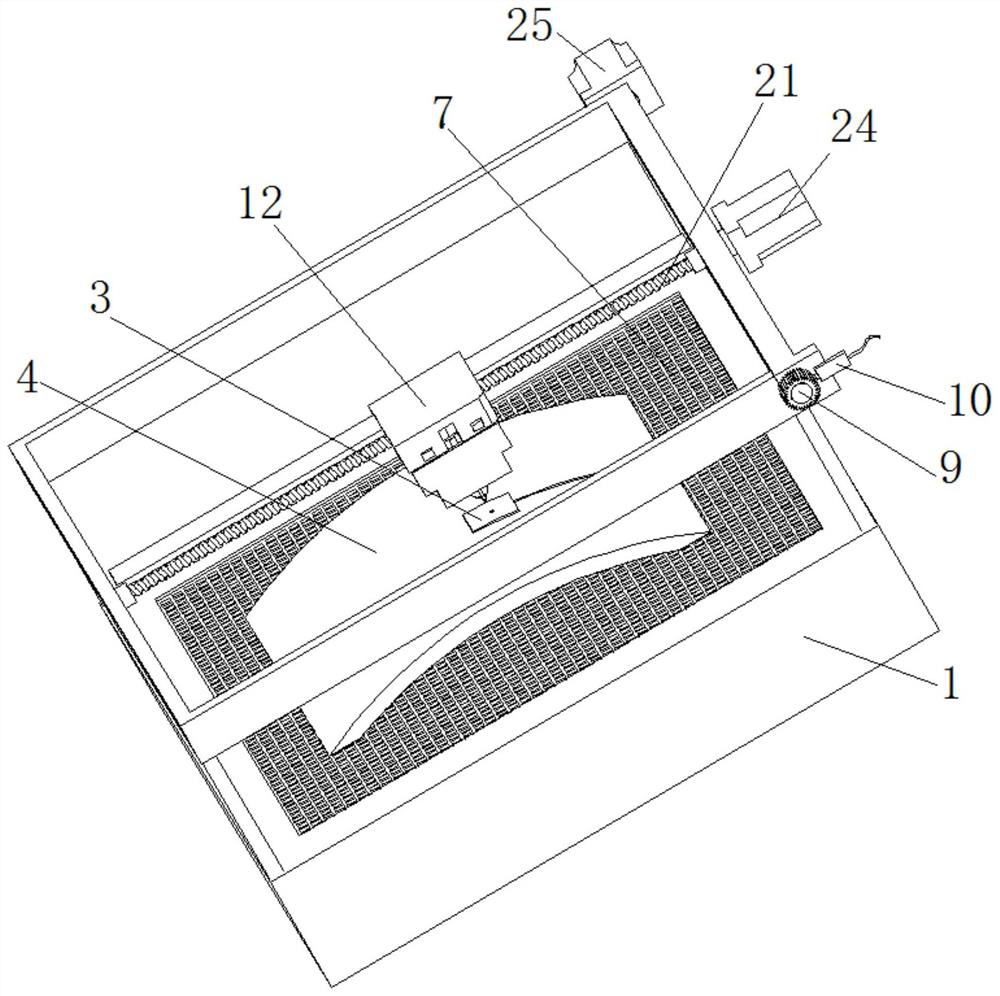

[0026] Such as Figure 1-5 Shown: a laser cutting machine applied to special-shaped sheet metal parts, including a frame 1, on which a driving part 2 is arranged, and the driving part 2 controls the laser cutting head 12 to move in the horizontal direction, so as to realize cutting of sheet metal parts. cutting.

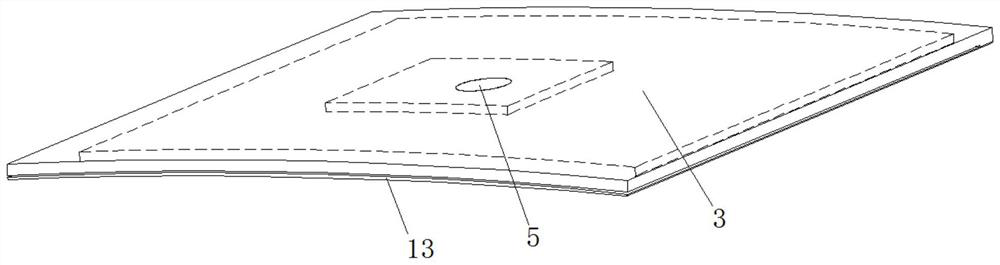

[0027] Considering the occurrence of quality problems caused by waste materials, splashing of sparks and splashing during the laser cutting process, the agglomeration of the sheet metal material at the cutting edge, etc., this scheme sets up a protective block 3 that moves synchronously with the laser cutting head 12. The cutting slot 5 is reserved on the body 3, and the protective block 3 is placed on the upper surface of the sheet metal, so that the splashed waste, sparks, etc. fall on the protective block 3, which protects the sheet metal to a certa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com