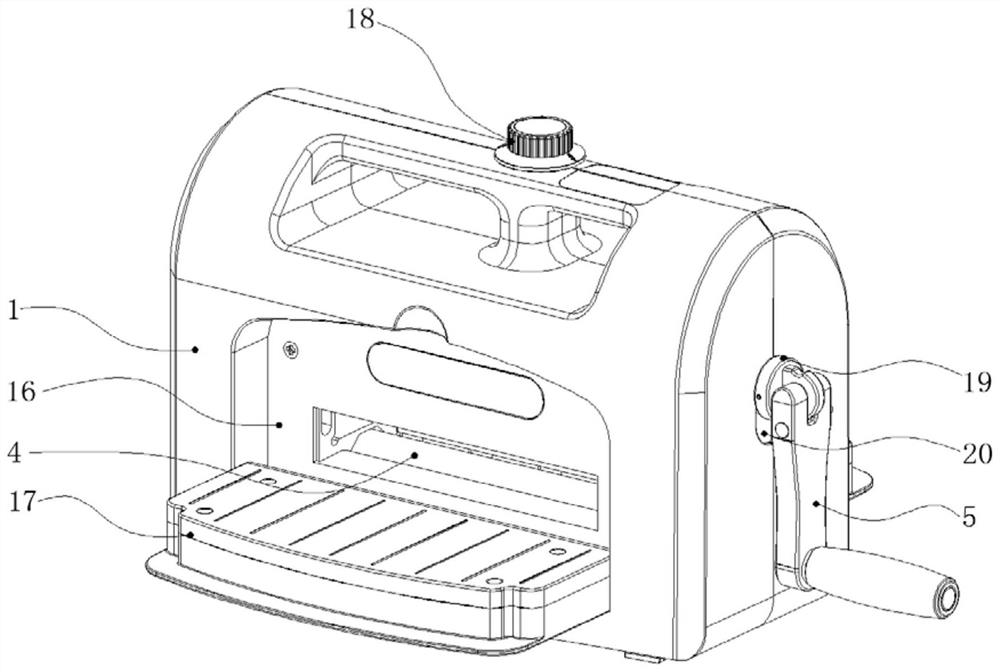

Hand-cranking type multifunctional paper art embossing machine with adjustable roller distance

An adjustable and multi-functional technology, applied in metal processing, etc., can solve the problems of reducing product life, affecting embossing quality, and increasing production costs, so as to prolong service life, improve embossing quality, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

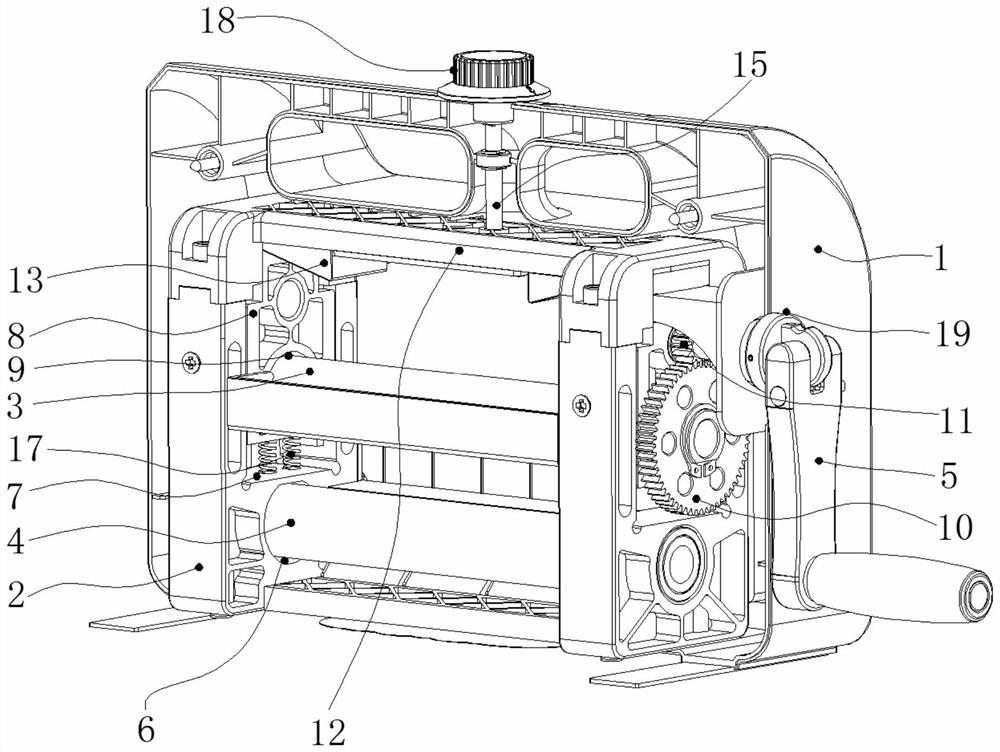

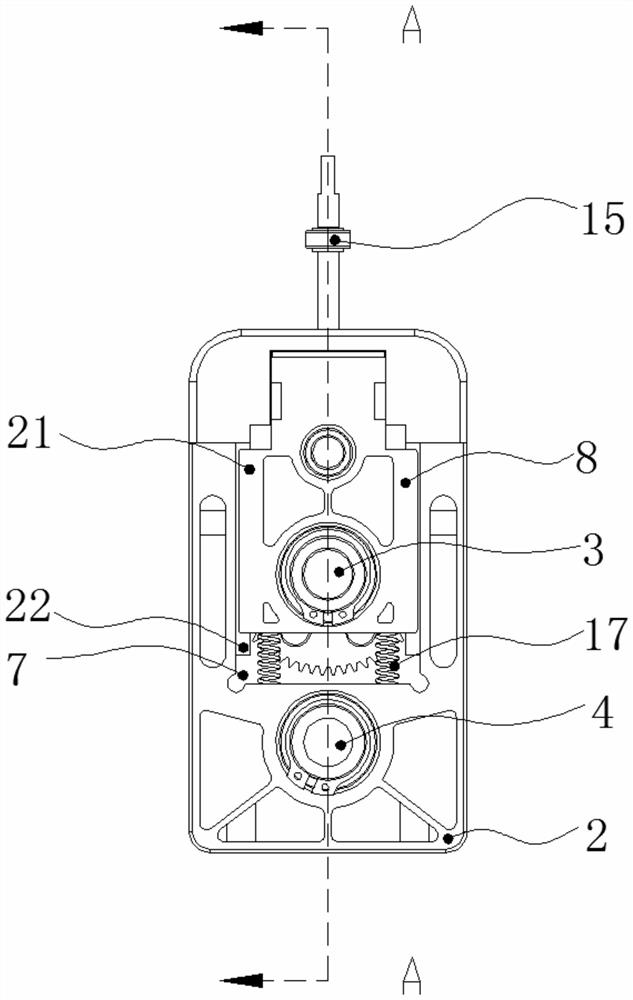

[0037] By having a knob on the top of the mechanical housing, the second transmission gear is rotated and drive the second large gear rotation, and then the pair of racks engaged in the second large gear in the horizontal direction in the horizontal direction; clockwise When the knob is pulled, a pair of racks slides outward, the rack is squeezed with the lifting slider provided with the slope, so that the lifting slider slides in the vertical direction, at which time the lift slider The bottom of the spring is compressed, which drives the upper sleek, so that the spacing of the upper axle and the lower swear will be reduced; finally stack the pad, paper, knife mold, insertion between the upper radial and lower swearing, and then shake The handle holder, the first transmission gear shaft drives the first large gear that meshes thereto, and the upper slew starts synchronous transport, and there is no generic transmission, and the friction of the pad is used to perform auxiliary rot...

Embodiment example 2

[0039] By having a knob on the top of the mechanical housing, the second drive gear is rotated and drive the second large gear rotation, and then a pair of racks engaged in the second large gear in the horizontal direction in the slot; counterclockwise When the knob is knob, a pair of racks simultaneously slide inward, release the lifting slider on the same side. At this time, the spring at the bottom of the slider is released, and the pushing the lifting slider slides up in the vertical direction, thereby driving the upper sword. Slide up, the spacing of the upper axle and the lower radial is increased; and finally stack the pad, paper, knife mold, insertion between the upper and lower swearing, and then hold the handle, the first drive gear shaft is driven. The first large gear that meshes it, the upper radial begins synchronous transport, and there is no generic transmission, and the auxiliary rotation is carried out using the friction of the pad.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com