Combined lever frame trailer

A combined type, frame technology, applied in the direction of motor vehicles, goods transport vehicles, loading and unloading vehicle arrangements, etc., can solve the problem of labor-intensive, and achieve the effect of reducing labor, strong practicability, and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

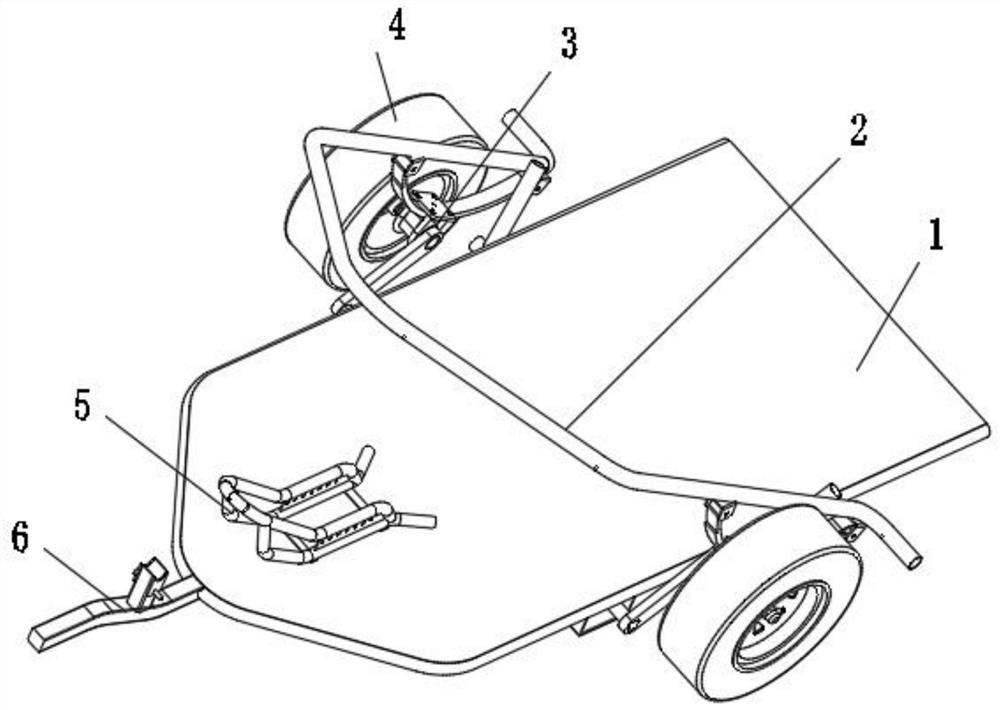

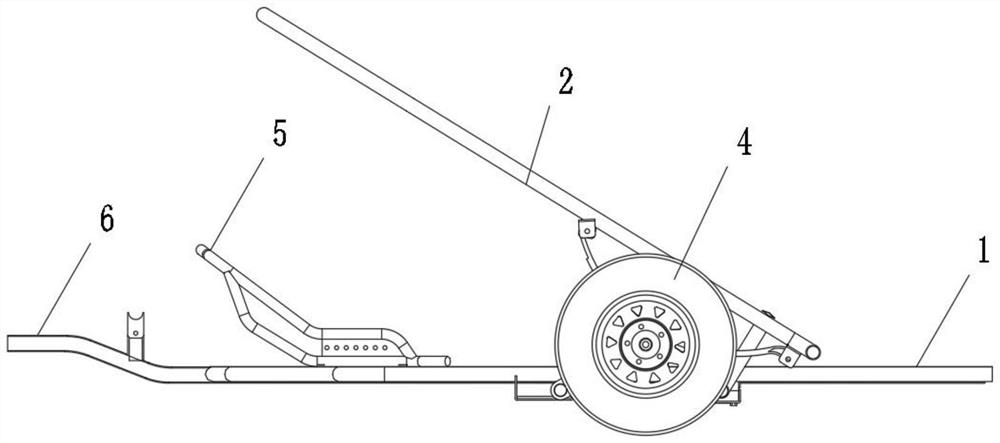

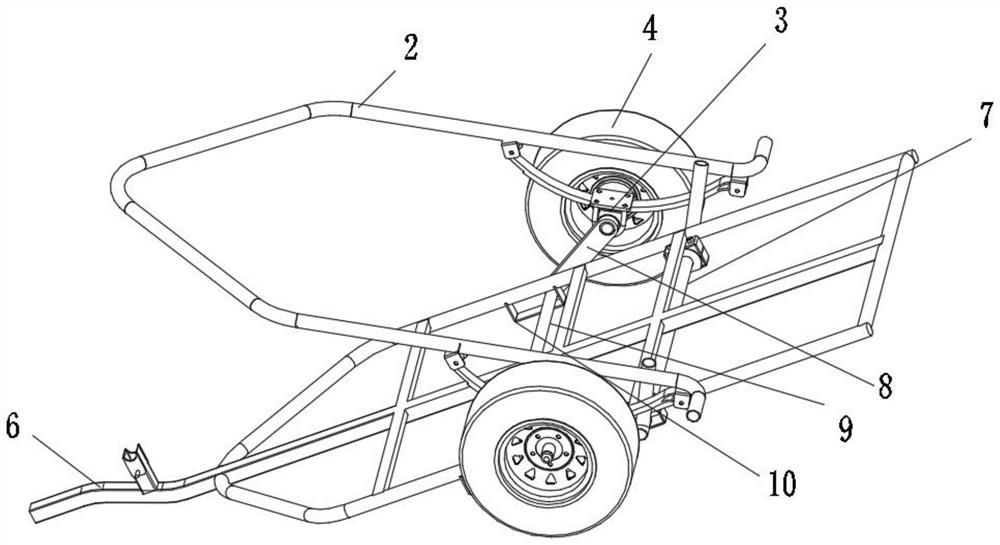

[0030] Such as figure 1 , 2 As shown, the embodiment of the present invention provides a combined lever frame trailer, comprising: a frame on which a bottom plate 1 is arranged; two sliding assemblies 10 are arranged oppositely at the bottom of the frame; A support shaft 9 is arranged between them, and the end of the support shaft 9 passes through the sliding assembly 10 and is connected with a connecting rod 8, and the axis of the connecting rod 8 and the support shaft 9 is perpendicular; the end of the connecting rod 8 away from the support shaft 9 is connected with the rolling assembly 4 , the rotating shaft of the rolling assembly 4 and the end of the connecting rod 8 away from the supporting shaft 9 are fixed; a lever structure 3 is also included, the power arm 2 of the lever structure 3 is arranged above the vehicle frame, and the fulcrum structure of the lever structure 3 is arranged on the rotating shaft of the rolling assembly 4 On, the resistance arm of lever struct...

Embodiment 2

[0035] On the basis of Embodiment 1, in order to make the force at the point of action of the resistance arm more balanced, one end of the resistance arm of the lever structure 3 away from the fulcrum structure is connected with a support rod 7 through a connecting piece, and the support rod 7 is erected on the vehicle through a bracket. bottom of the shelf.

Embodiment 3

[0037] On the basis of embodiment 1, when carrying out consignment to motorcycle, be provided with the position-limiting structure I5 that is used to limit the movement of wheel on the bottom plate 1 top, position-limiting structure I5 comprises two support frames that are arranged oppositely, and the position-limiting structure I5 of support frame The bottom and the bottom plate are fixed, the end of the support frame away from the rear of the frame is closed, and the end close to the rear of the frame is open, wherein the two support frames are correspondingly provided with vertically arranged connecting plates, and the connecting plates are provided with A plurality of holes, between the two corresponding holes on the two connecting plates, is used to install the limiting structure II to prevent the rotation of the wheel. In the hole, to adapt to the limit of the wheels of different diameters.

[0038] Wherein, a traction structure 6 is also included, and the traction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com