Improved anti-theft butterfly valve

An improved, butterfly valve technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of inability to automatically switch the valve function, inconvenient disassembly and maintenance, etc., to enhance stability, improve rotation function, and improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

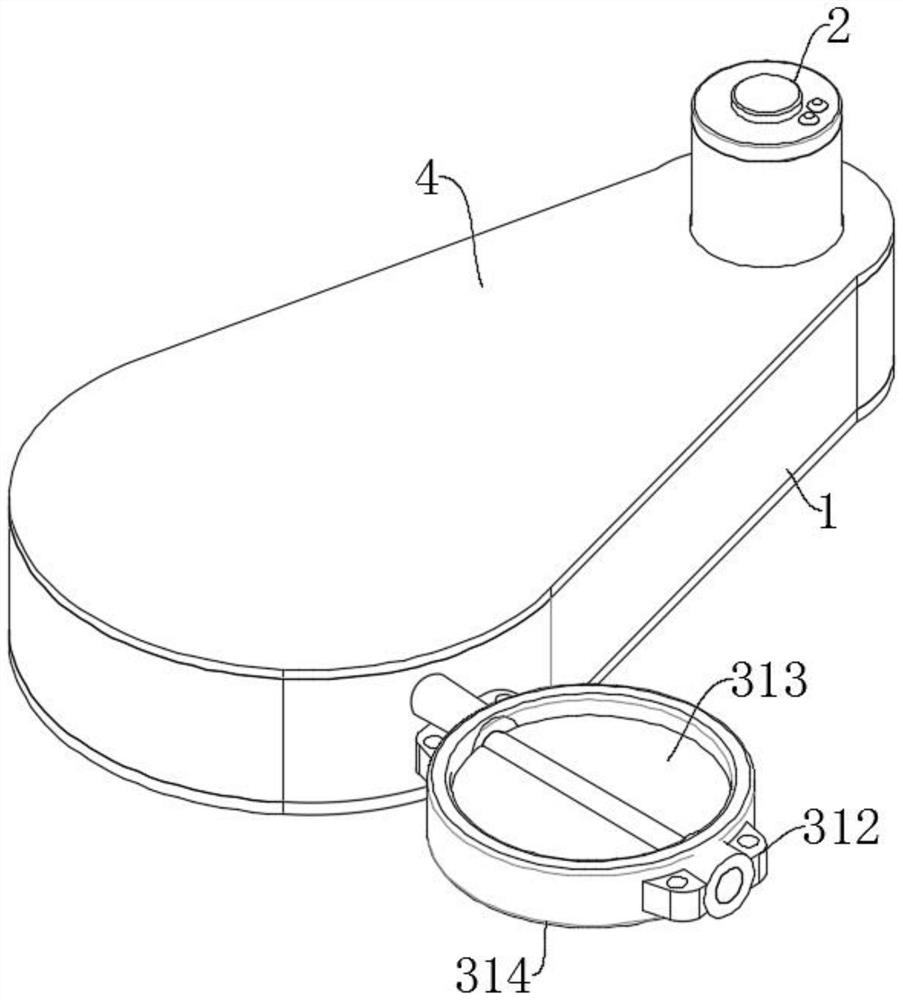

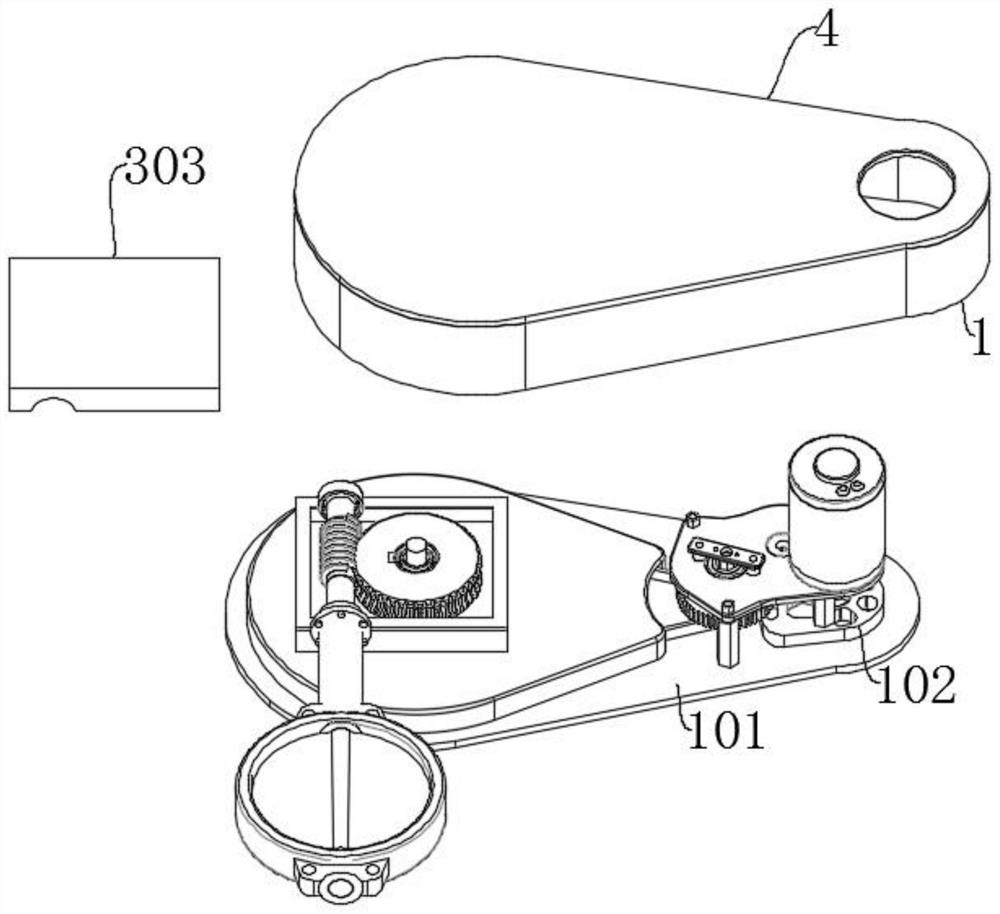

[0041] see Figure 1-10 , the present invention provides the following technical solutions:

[0042] An improved anti-theft butterfly valve, including:

[0043] Bottom plate 101;

[0044] The first fixed block 102, the first fixed block 102 is fixedly connected to the upper end of the base plate 101, the upper end of the first fixed block 102 is fixedly connected with a rhombus rod 103, and the upper end of the rhombic rod 103 is fixedly connected with a second fixed block 104; and

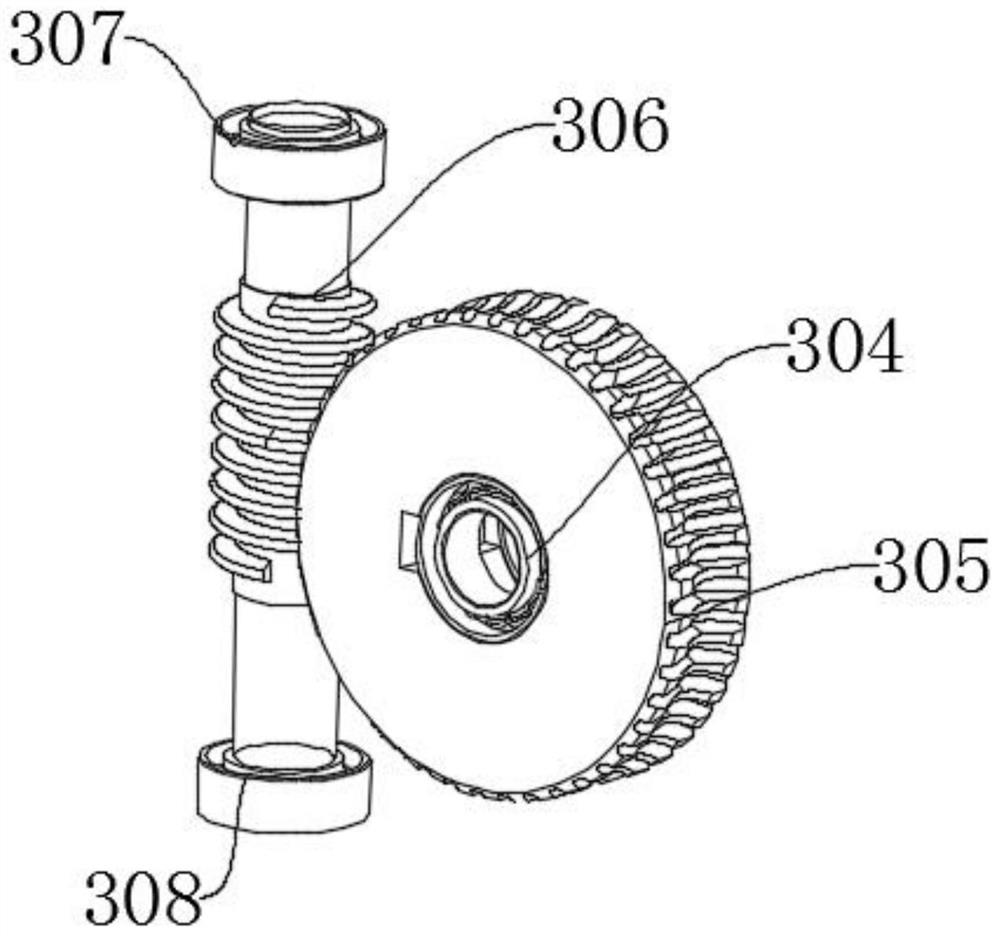

[0045] Turning mechanism; the turning mechanism includes a second gear 204, a third gear 205, a second rotating bearing 206, a fourth gear 207, a first I-shaped wheel 208, a fourth rotating bearing 209, a second I-shaped wheel 210, and a connecting belt 211 , the eighth rotating bearing 212 and the driving part, the second gear 204 is fixedly connected to the upper end of the base plate 101 through the rotating shaft, the third gear 205 is fixedly connected to the lower end of the third gear 205, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com