A device for detecting the strength of building materials

A technology for building materials and strength detection, applied in the field of detection, can solve problems such as poor detection and characterization capabilities, and achieve the effects of increasing detection capabilities, improving continuity, and realizing sequential detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

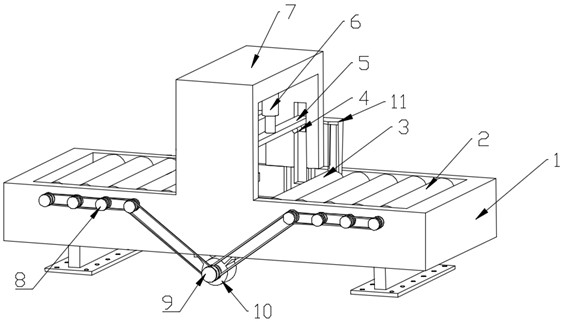

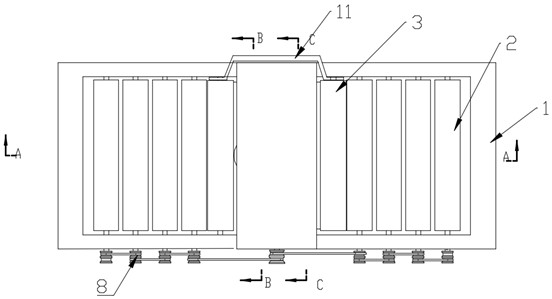

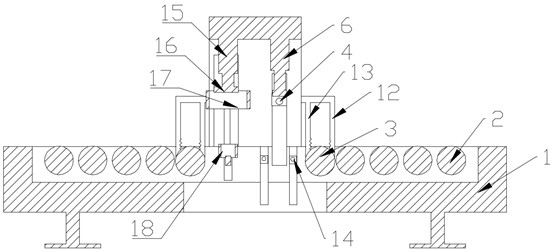

[0033] refer to Figure 1~Figure 3 In this embodiment, a building material strength detection device is proposed, which is used for strength detection of building panels, and the building material strength detection device includes: a workbench 1, a support frame 7, a first drive telescopic rod 6 and The second drives the telescopic rod 15 .

[0034] The workbench 1 is provided with support legs at the bottom, and the bottom of the support legs is fixedly connected with a backing plate, and the support legs support the workbench 1 to a specified height, and the setting of the backing plates increases the stability of the support legs. A through hole is provided on the backing plate, and the setting of the through hole is convenient for fixing the supporting legs by screws, thereby fixing the device. A support frame 7 is fixedly arranged on the workbench 1 .

[0035] The second installation frame 16 and the lifting frame 22 are relatively liftable and arranged inside the supp...

Embodiment 2

[0045] Two groups of transmission rollers 2 are arranged on the workbench 1 for relative rotation, and each group of transmission rollers 2 is provided with several. Drive pulley 8, connect by belt between each driven pulley 8, motor 10 is installed on the workbench 1, the coaxial output shaft of motor 10 is fixedly connected with drive pulley 9, and drive pulley 9 is connected with driven pulley 8 by belt, In this way, the transmission of building materials can be completed. When the conveying roller 2 at one end conveys the building materials to the feeding roller 3, the conveying roller 2 stops conveying. The material is delivered. The feeding roller 3 and the conveying roller 2 are provided with a rubber layer, and the conveying roller 2 and the driven pulley 8 are unidirectionally driven. When the feeding roller 3 conveys intermittently, the conveying roller 2 rolls to avoid hindering the building materials. Thereby, the smoothness of the transmission of the feed drum 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com