Production order management system

A management system and production order technology, applied in manufacturing computing systems, data processing applications, instruments, etc., to achieve the effects of improving management capabilities, optimizing management capabilities, and solving large material inventories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] Example 1

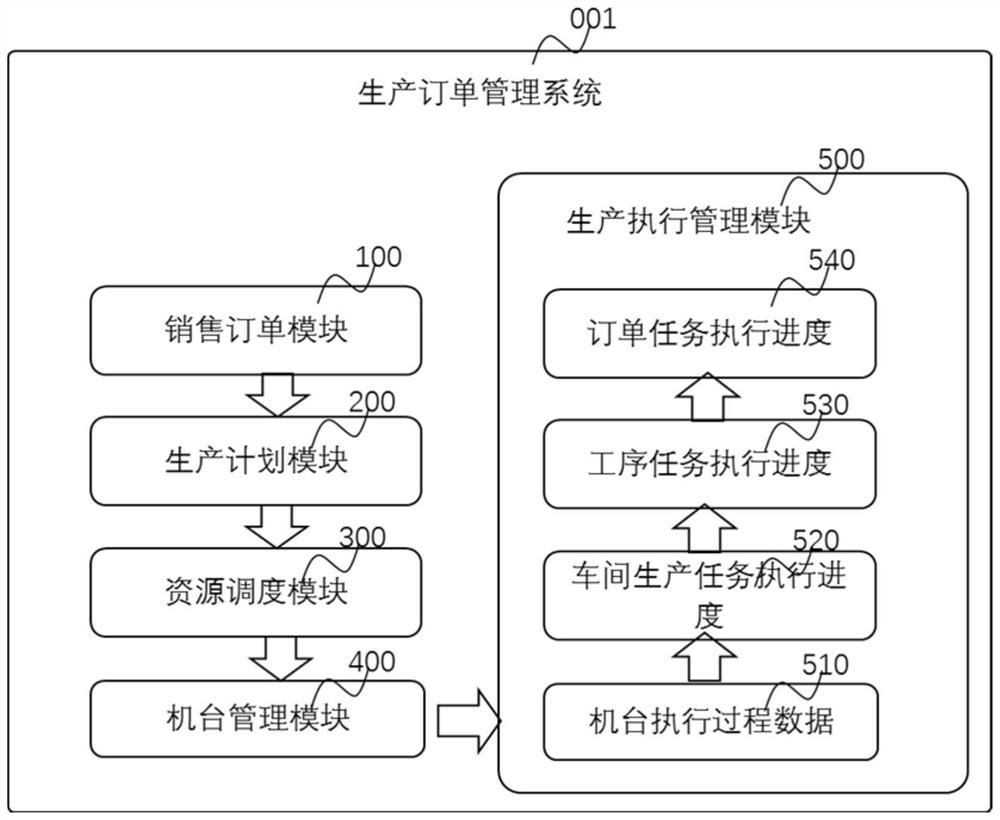

[0024] like figure 1 As shown, it is an illustration of a production order management system 001 embodiment of the present invention, including: sales order module 100, production planning module 200, resource scheduling module 300, machine management module 400, production execution management module 500.

[0025] The sales order module 100 issues an order task to the production plan module 200, the production plan module 200 receives the order task, performs production scheduling and generates a production plan. The order task includes one or more information of customer information, finished product requirements, process requirements, raw material requirements, packaging requirements, delivery requirements, communication requirements. The production plan includes one or more of delivery, process, raw materials, quality standards. When the production order management system 001 is applied to printing and dyeing enterprises, the processes include: a variety of ...

Example Embodiment

[0039] Example 2

[0040] This embodiment provides a production order management system in the field of printing and dyeing fabrics, mainly in the specific application of all production order management systems in the printing and dyeing cloth in Example 1.

[0041] The workshop layer in the field of production and processing in the printing and dyeing cloth includes: white blank warehouse, front treatment workshop, printing / dyeing shop, post-finishing workshop, stereotype, surgical workshop; the workshop scheduling module is in the white blank warehouse, front treatment , Printed / dyeing workshop, step-by-duty workshop, surfaculation workshop, or cross-car implementation resource allocation, and generate production tasks.

[0042] Through the application of the production order management system in the field of printing and dyeing cloth, it is greatly solved the communication cost of printing and dyeing cloth production enterprises, with a single difficult, and customers also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com