Compression-resistant composite cable and preparation method thereof

A composite cable and cable core technology, which is applied in the manufacture of cables/conductors, insulation of conductors/cables, circuits, etc., can solve problems such as the inability to prepare compression-resistant cables, and achieve the effect of increasing compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below with reference to the accompanying drawings.

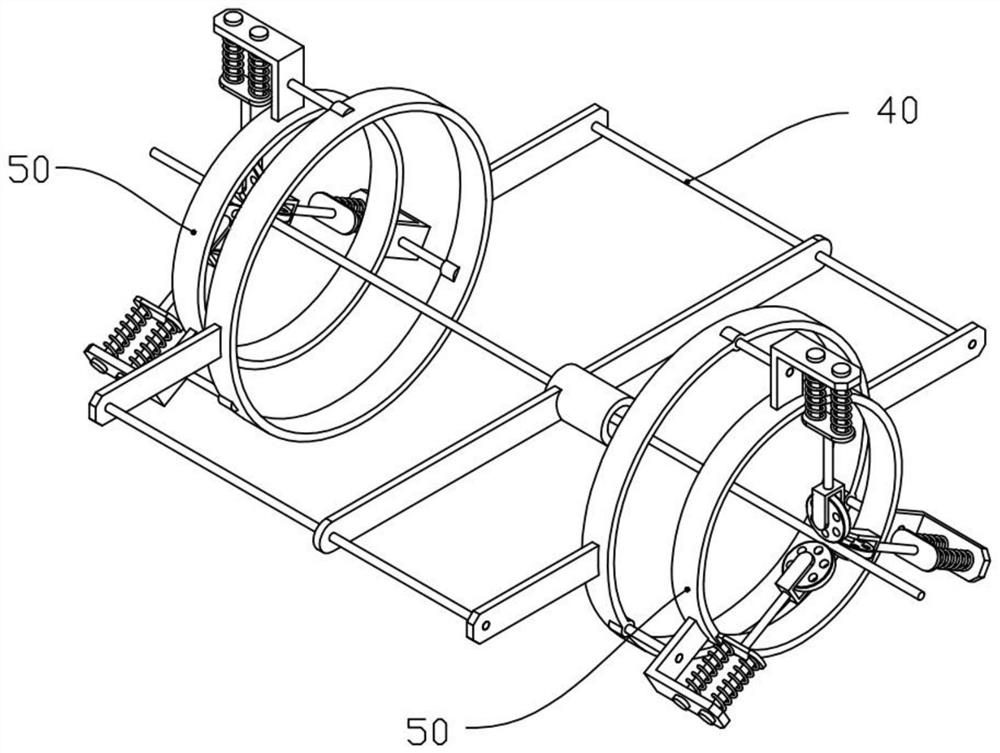

[0030] By below Figure 1 to 10 DESCRIPTION present embodiment, a compression method for preparing a composite cable, the method comprising the steps of:

[0031] Step a: a cable core feeding mechanism 10 passes through the rear side of the apparatus 50 Preparation of compression of the composite cable, the feeding mechanism 90 and the front side 50 of the injection mechanism;

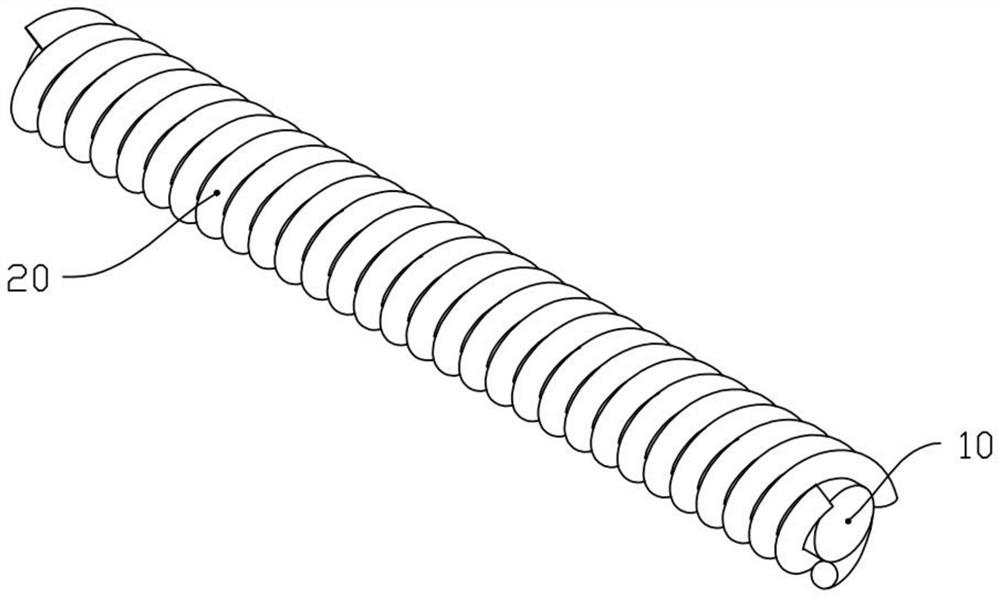

[0032] Step two: three rotation bodies through the rubber column 80 is wound around the cable core 10, three rotation drive mechanism 80 rotating the rubber column 10 is wound around the cable core 20 is formed of rubber spiral column;

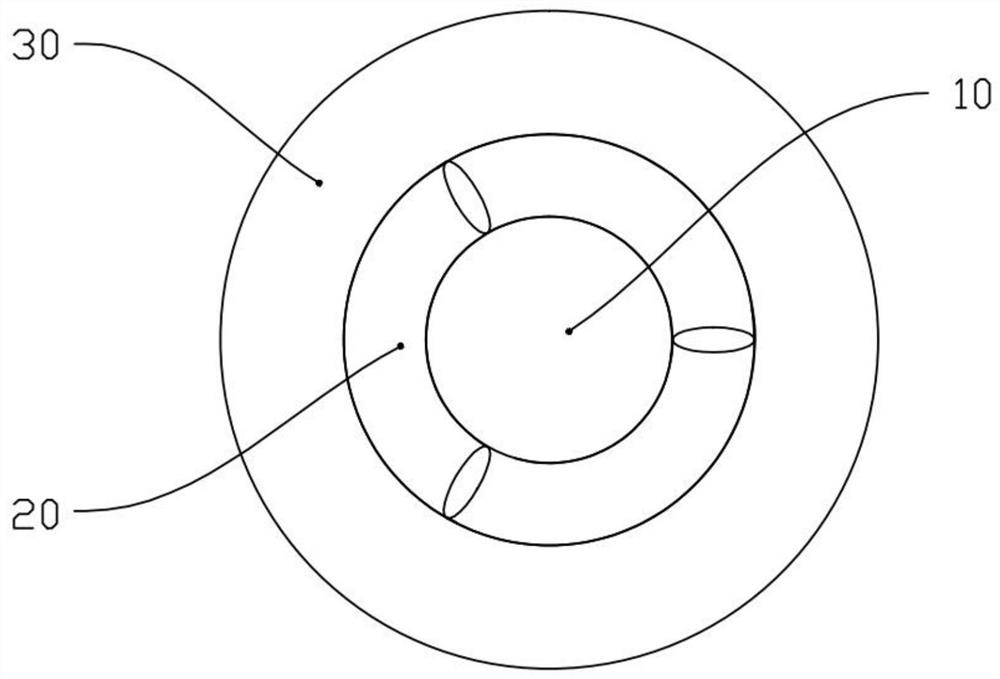

[0033] Step Three: injection mechanism 90 and the cable core 10 column three rubber coil 20 is formed by injection insulating jacket 30.

[0034] When the rotary drive mechanism 70 is rotated three column rotation rubber wound on the cable core 20 is formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com