Ultrasound transducer assembly having low viscosity kerf fill material

A technology for ultrasonic transducers and filling materials, which can be used in piezoelectric devices/electrostrictive devices, ultrasonic/sonic/infrasonic diagnosis, piezoelectric/electrostrictive/magnetostrictive devices, etc., and can solve problems such as crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

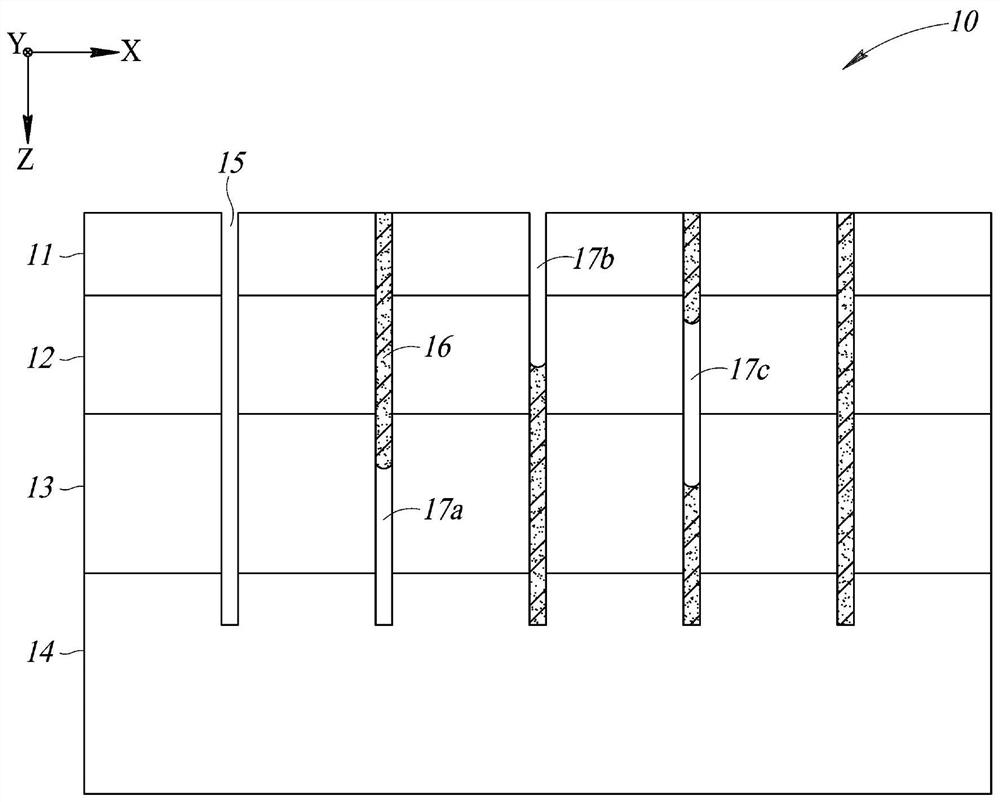

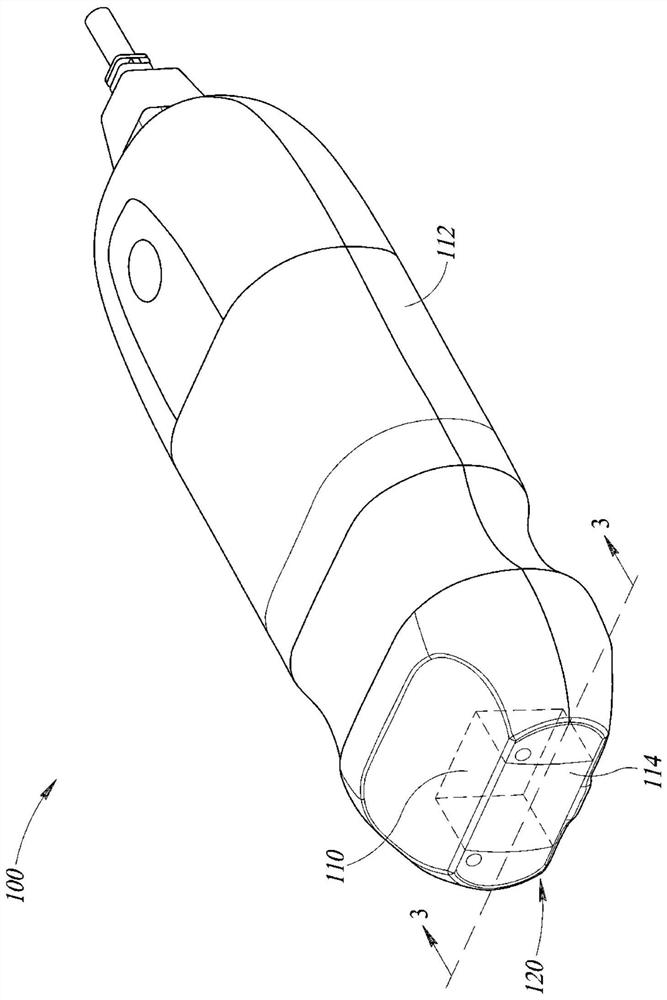

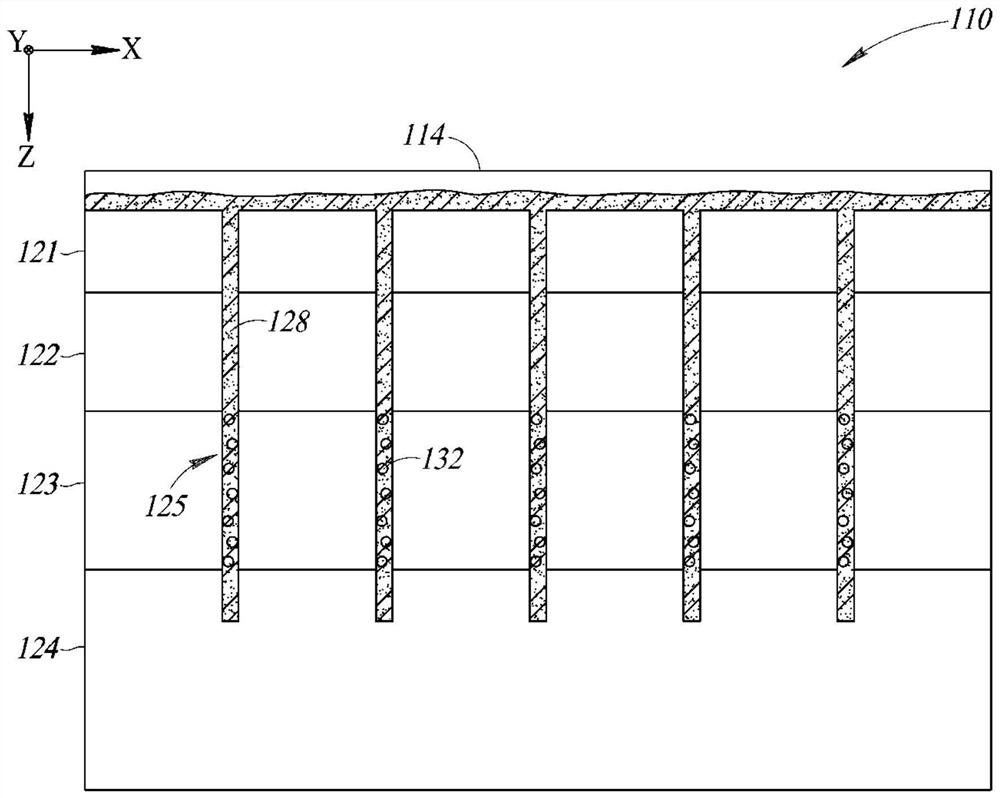

[0013] An ultrasound transducer assembly may include an acoustic backing, a plurality of piezoelectric transducer elements on the acoustic backing, and one or more matching layers on the transducer elements. A plurality of cutouts extend through the matching layer and separate adjacent transducer elements from each other. The incision is filled with an incision filling material that includes a first material, such as RTV silicone, and a solvent that reduces the viscosity of the incision filling material, such as a volatile methylsiloxane (VMS) fluid.

[0014] By reducing the viscosity of the incision filling material, more complete filling of the incision can be achieved. In addition, the reduced viscosity incision filling material facilitates the inclusion of one or more additives into the incision filling material while maintaining a viscosity suitable for completely filling the incision. Such additives may be included to modify the properties of the incision filling materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com